Design method of full-dynamic mobile robot chassis with self-adaptive adjustment function

A mobile robot and self-adaptive adjustment technology, applied in the direction of motor vehicles, elastic suspensions, suspensions, etc., can solve the problems of not being able to turn quickly, slow moving speed, high price, etc., to improve the ability to overcome obstacles, ensure stability, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

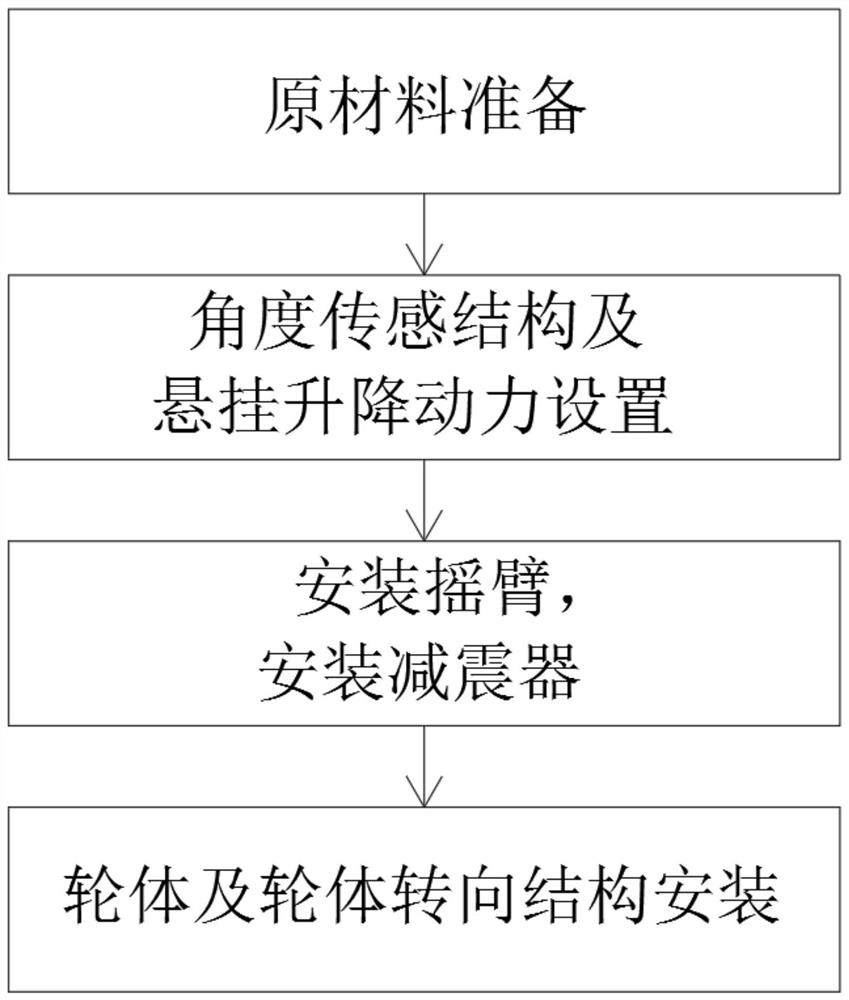

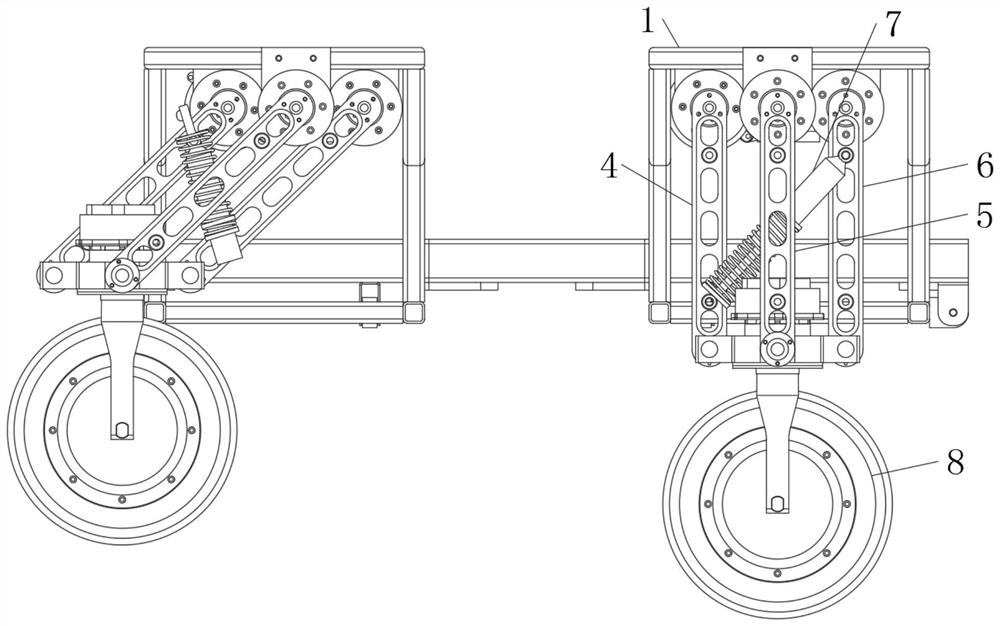

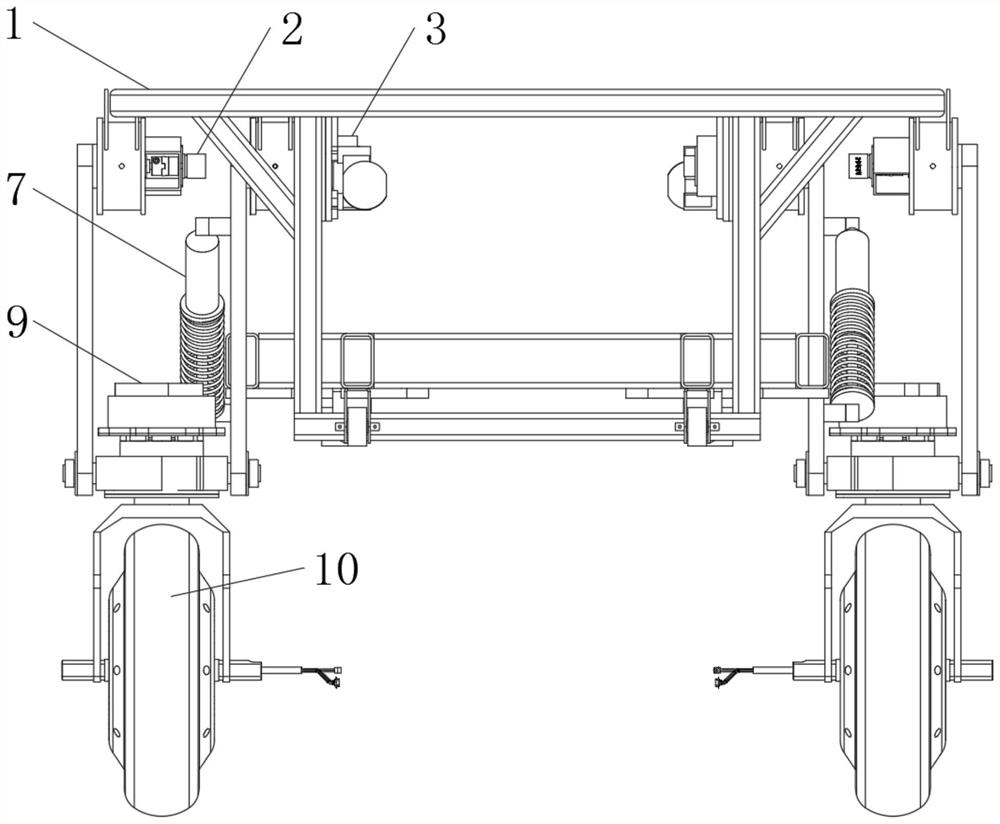

[0042] See Figure 1-5 Fully dynamic mobile robot chassis design method with adaptive adjustment function, including raw material preparation - angle sensing structure and suspension lifting power setting - mounting rocker arm, mounting shock absorber 7-wheel body and wheel steering structure mounting design steps, Specific steps are as follows:

[0043] (1) Raw material Preparation: A certain amount of frame body 1, angle sensor 2, suspended lift motor 3, rocker arm, shock absorber 7, tire, hub motor 10 and tire steering mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com