A vegetable processing equipment

A vegetable processing and equipment technology, applied in metal processing, etc., can solve the problems of inedible vegetable roots, large labor force, slow work efficiency, etc., and achieve good root removal effect, convenient centralized collection, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

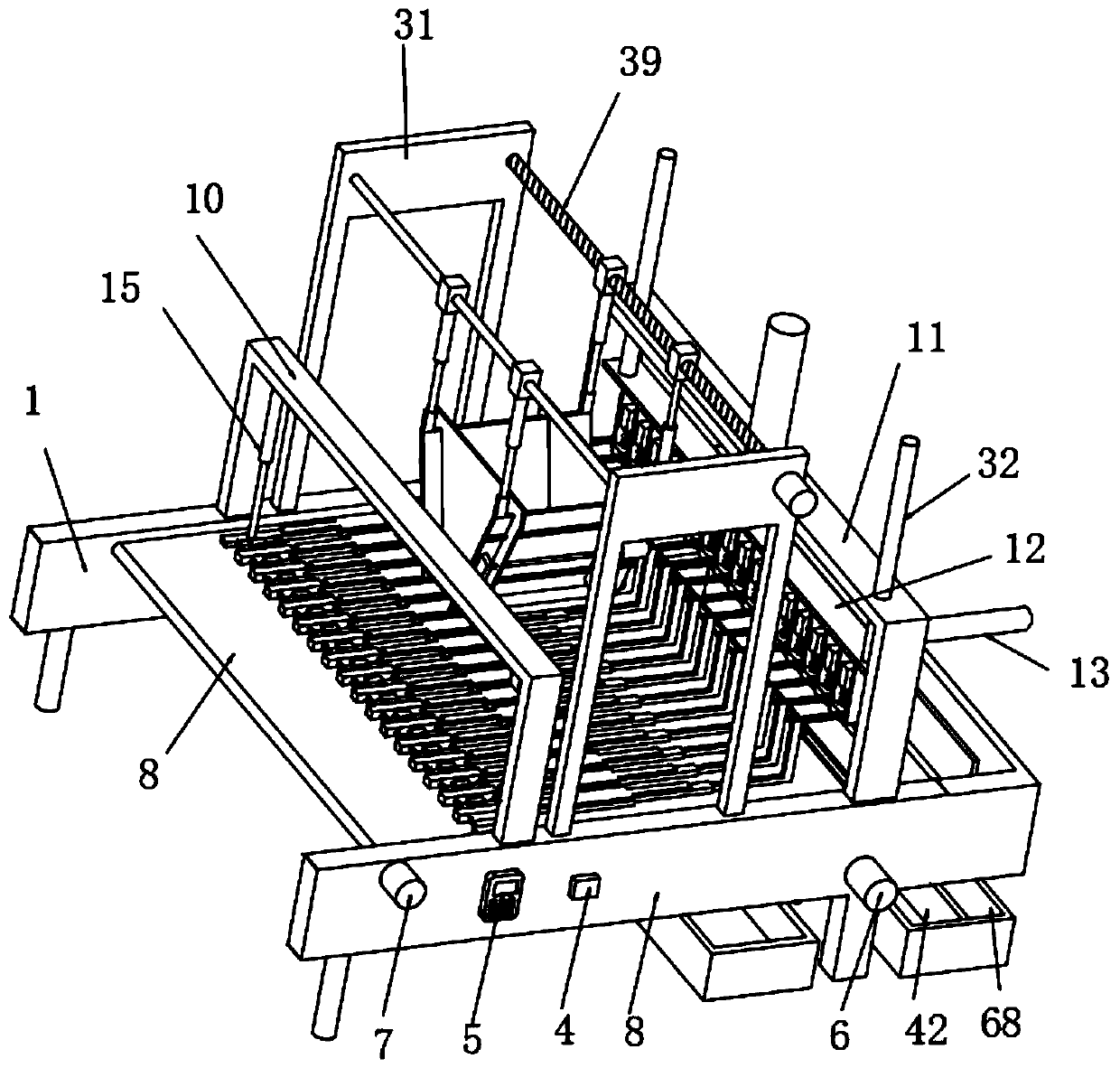

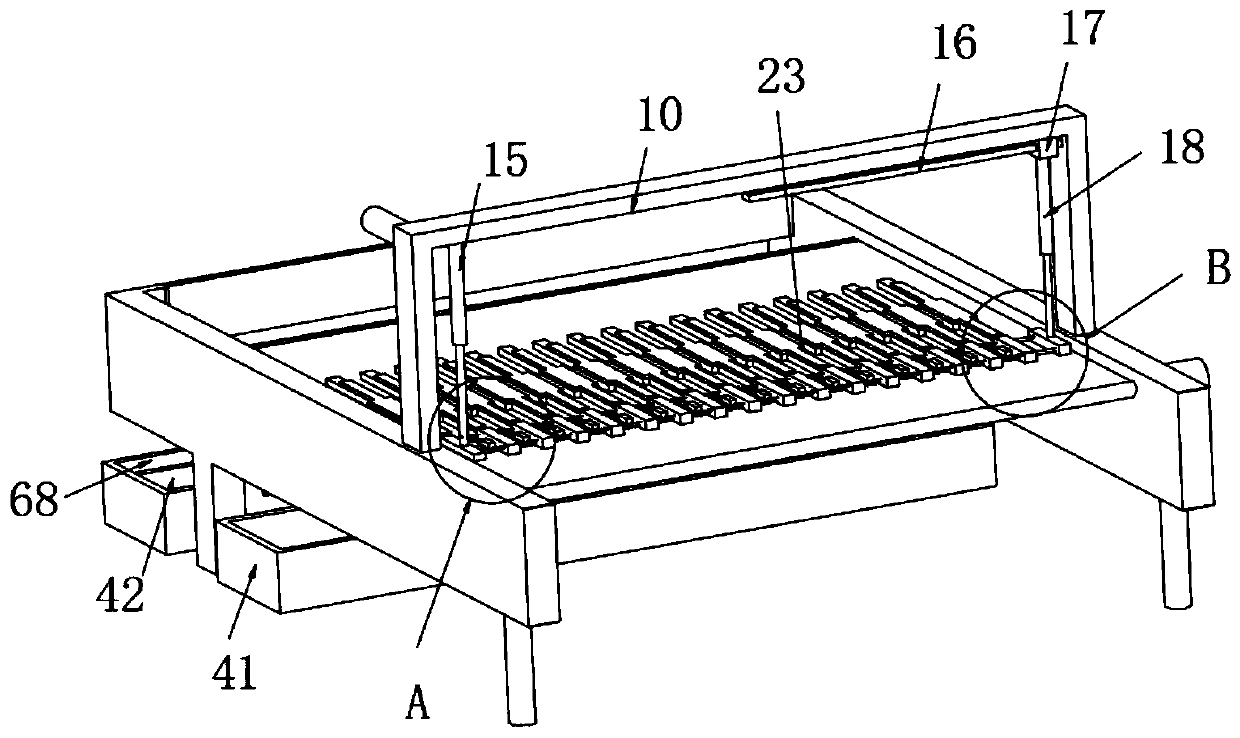

[0039] Example 1, please refer to Figure 1-8 , the present invention provides a technical solution: a vegetable processing equipment, including a frame 1, a control panel 5, a conveyor belt 8, a cutting platform 9, a mounting frame 10, a support frame 11, a cutting device 12, a feeding device 39 and a guide Material plate 40, the inner side of the frame 1 is provided with a driving shaft 2 and a driven shaft 3, and the two ends of the driving shaft 2 and the driven shaft 3 are respectively connected to the inner walls of the corresponding two sides of the frame 1 through bearings. , a side wall of the frame 1 is fixed with a current regulator 4, a control panel 5, a guide motor 6 and a drive motor 7, and the output shaft of the drive motor 7 is fixedly connected with one end of the drive shaft 2 through a coupling, The driving shaft 2 is connected to the driven shaft 3 through a transmission belt 8. A cutting platform 9 is fixed on the inside of the frame 1, and the cutting p...

Embodiment 2

[0040] Embodiment 2, the inside of the frame 1 is located directly below the cutting platform 9 and is provided with a material guide plate 40, and both ends of the material guide plate 40 are rotatably connected to the inner walls of the corresponding two sides of the frame 1 through bearings. The output shaft of the guide motor 6 is fixedly connected with one end of the material guide plate 40 .

Embodiment 3

[0041] Embodiment 3, the inner side of the frame 1 facing the material guide plate 40 is provided with a finished product trough 41 , an old root storage trough 68 and a recycling trough 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com