Novel automobile injection molding nozzle

A technology for injection nozzles and automobiles, applied in the field of molding tools, can solve problems such as difficulty in meeting and impact on nozzle life, and achieve the effect of avoiding wear and promoting physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

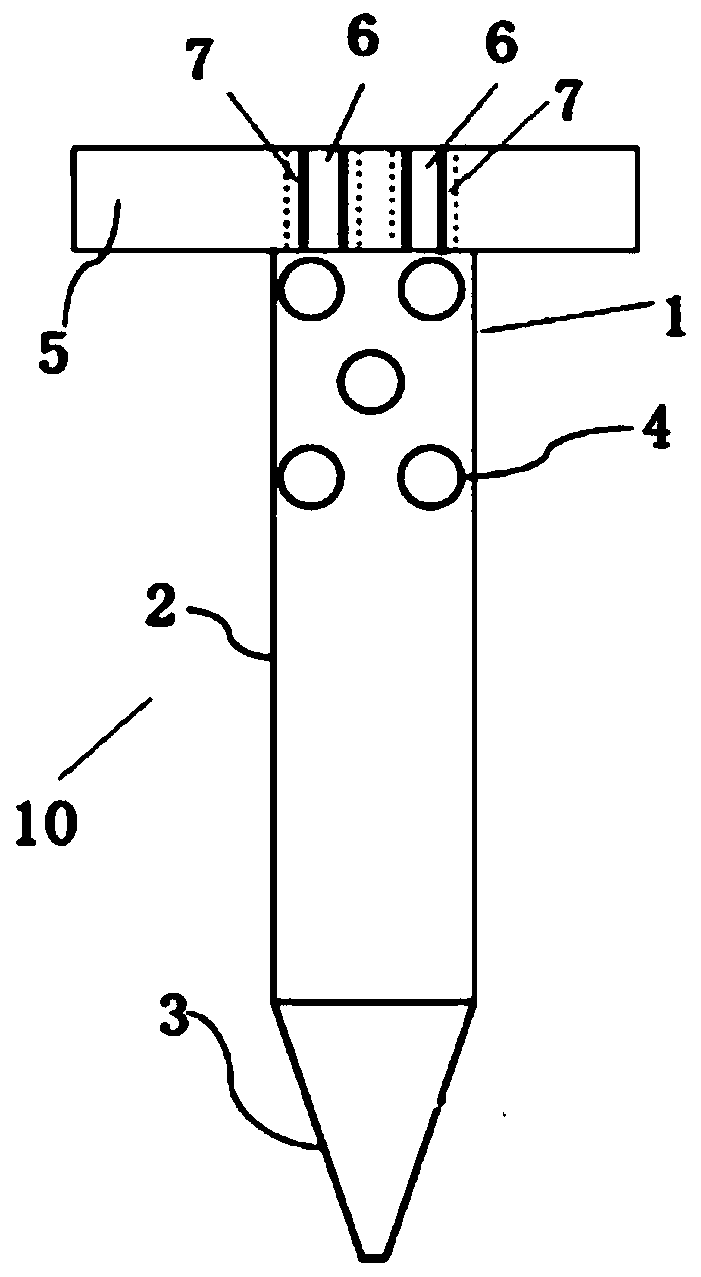

[0020] Such as figure 1 As shown, a new type of automobile injection molding nozzle of the present embodiment has an inlet 1, a nozzle chamber 2 and an outlet 3, the inlet 1 is connected with the injection molding material 4 in a molten state, and the nozzle chamber 2 is connected to the Injection molding material is introduced into the outlet 3 , wherein a heating device 5 is provided at the inlet 1 .

[0021] The invention continues to heat the injection molding material entering the nozzle inlet to ensure that it can be in a completely melted state when it enters the nozzle, and avoids the wear of the nozzle as a whole by the remaining particles during injection molding.

[0022] As an improved embodiment of the present invention, the heating device 5 includes: a porous channel 6 and a heating component 7 located on the outer wall of the channel. The injection molding material through the channel 6 is heated, and at the same time, the channel adjusts the injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com