Square and rectangular tube packing machine pressing device applying spring cotter and grooves and working method

A technology of a spring latch and a pressing device, which is applied in the directions of packaging and bundling machinery parts, etc., can solve the problems of the strength discount of solder joints, the disconnection of the packing tape of the rectangular tube, and the reduction of work efficiency, so as to ensure the welding quality and avoid the Economic loss, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

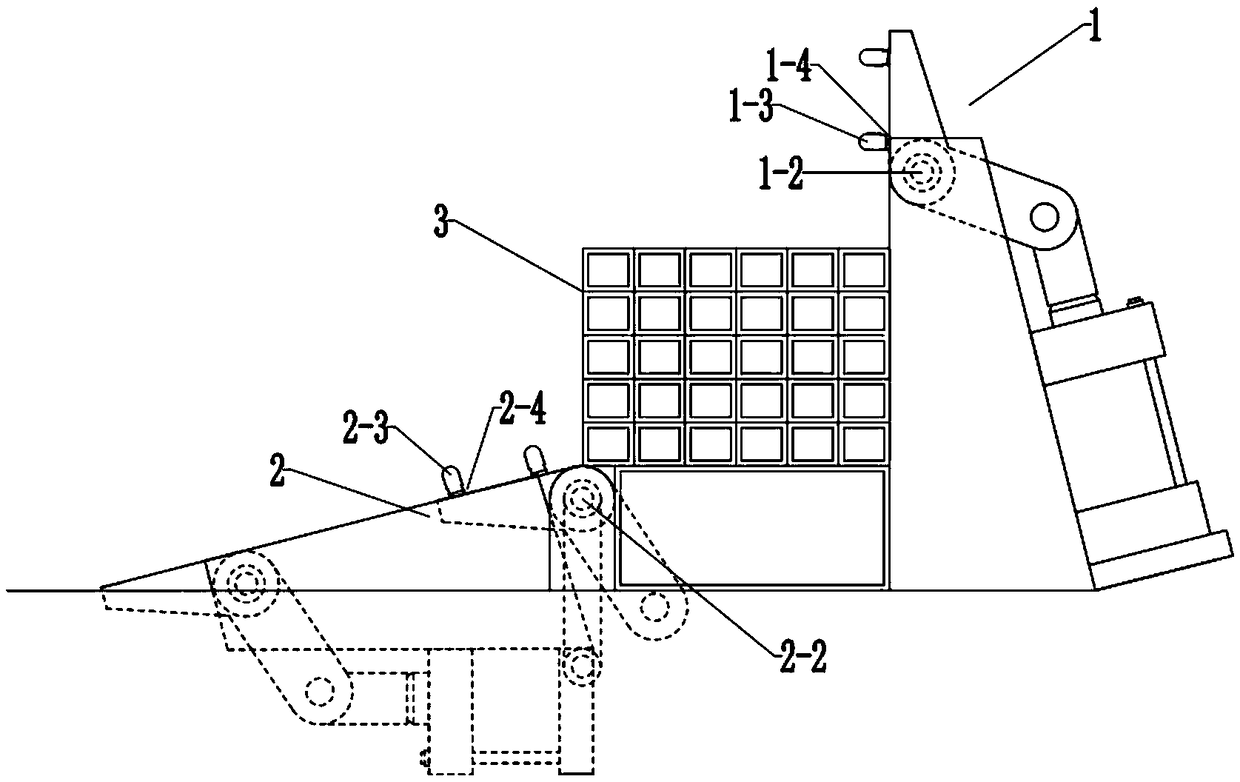

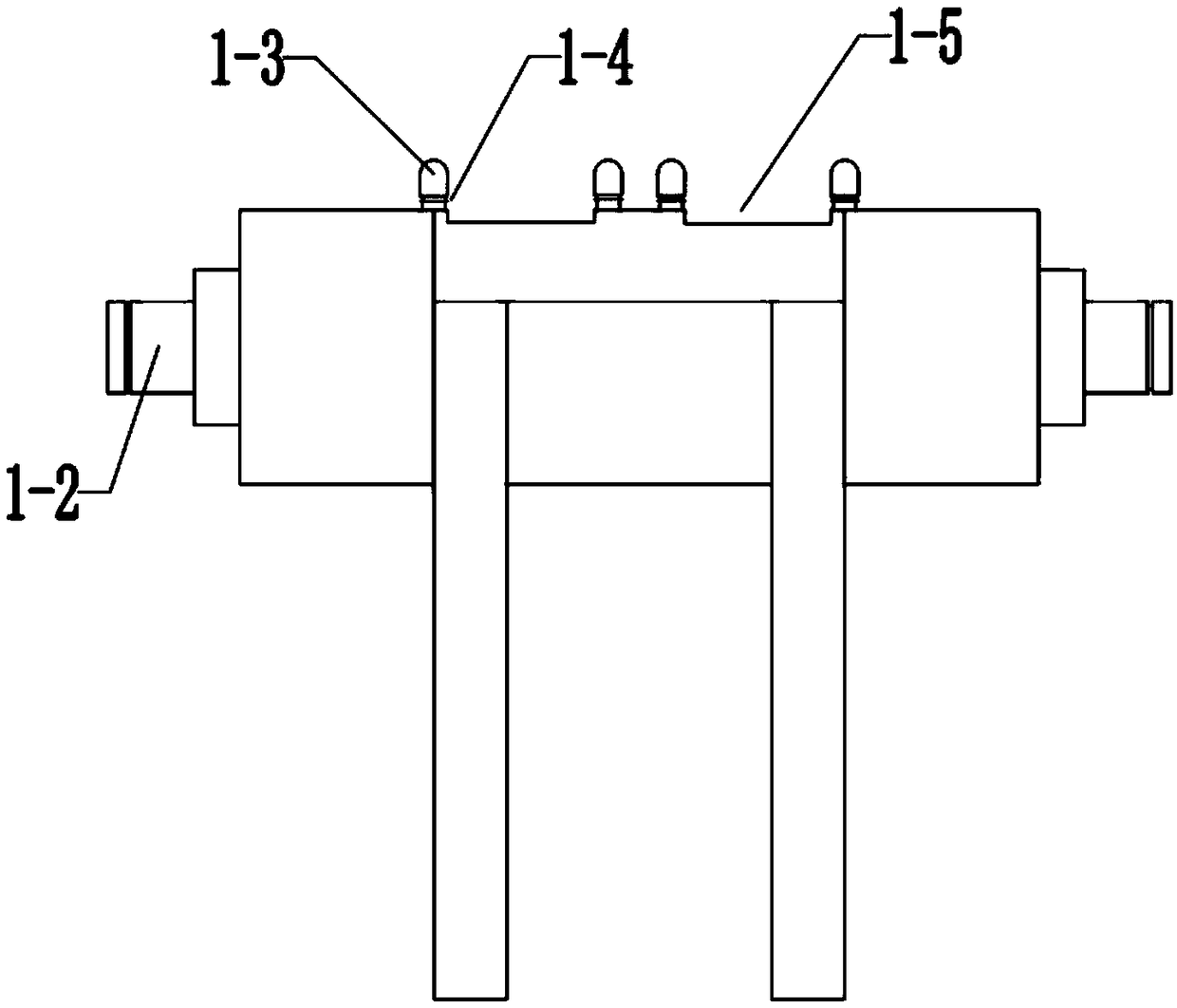

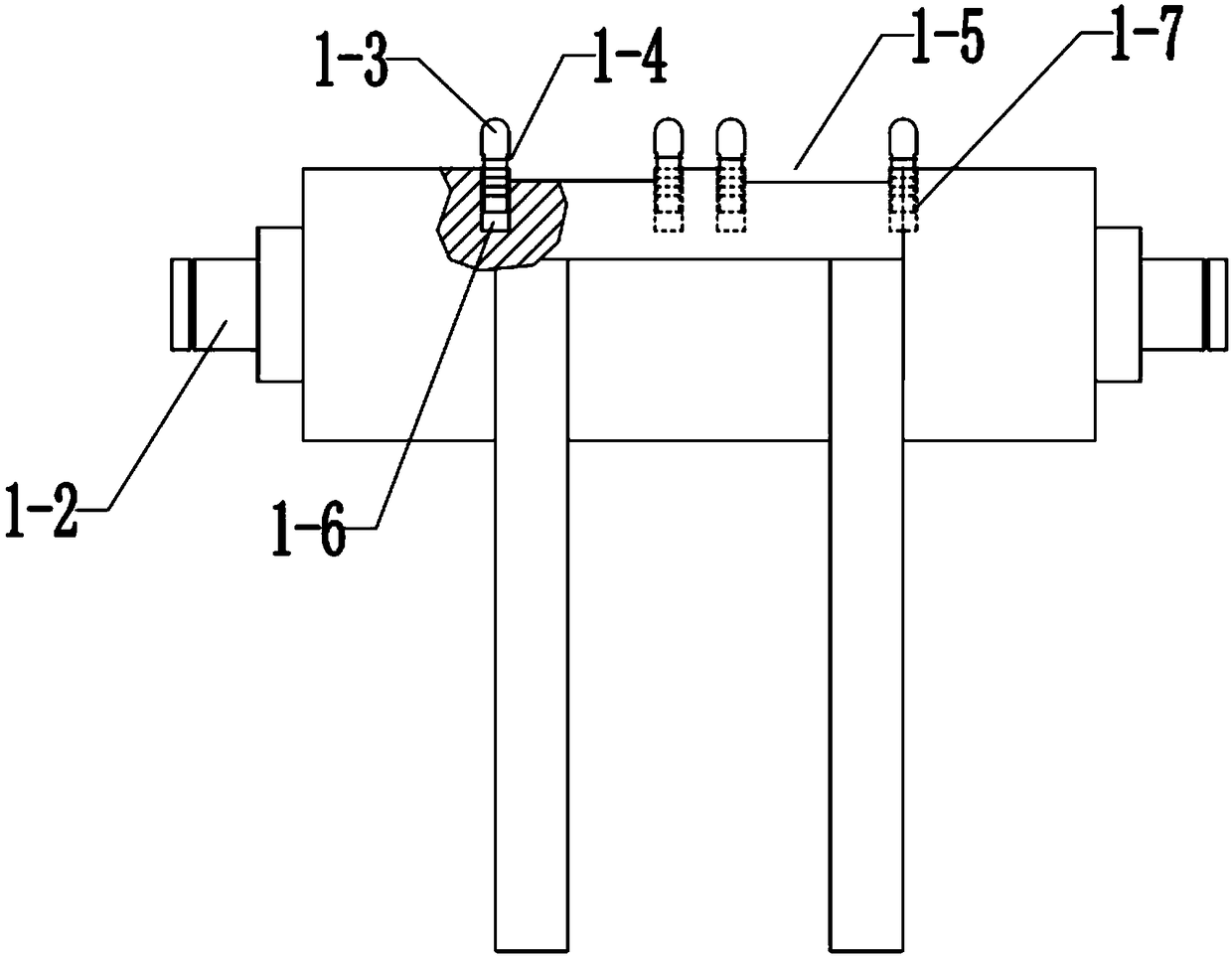

[0044] Embodiment: the compression device (see Figure 1-Figure 15 ), including a pressing plate A1 and a pressing plate B2, the pressing plate A1 includes a pressing plate A body 1-1 and an axis A1-2, the middle part of the pressing plate A body 1-1 is assembled with the axis A1-2, and the pressing plate B2 includes a pressing plate B Body 2-1 and shaft B2-2, the middle part of the press plate B body 2-1 is assembled with the shaft B2-2, which is characterized in that the working surface of the press plate A body 1-1 is used for positioning square tube packing belt groove A1-5, the direction of the groove A1-5 is along the direction of the rectangular tube packing belt, and the working surface of the pressing plate B body 2-1 has a groove B2 for positioning the rectangular tube packing belt -5, the direction of the groove B2-5 is along the direction of the rectangular tube packing belt, the number of the groove A1-5 and the groove B2-5 are the same and the positions correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com