Square and rectangular tube packer pressing device using cylinders and sliding blocks and operation method thereof

A technology of a pressing device and a working method, which is applied to the parts of packaging and bundling machinery, etc., can solve the problems of disconnection of square and rectangular tube packing belts, reduction of solder joint strength, and reduction of work efficiency, so as to avoid economic losses, welding Effects of quality assurance and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

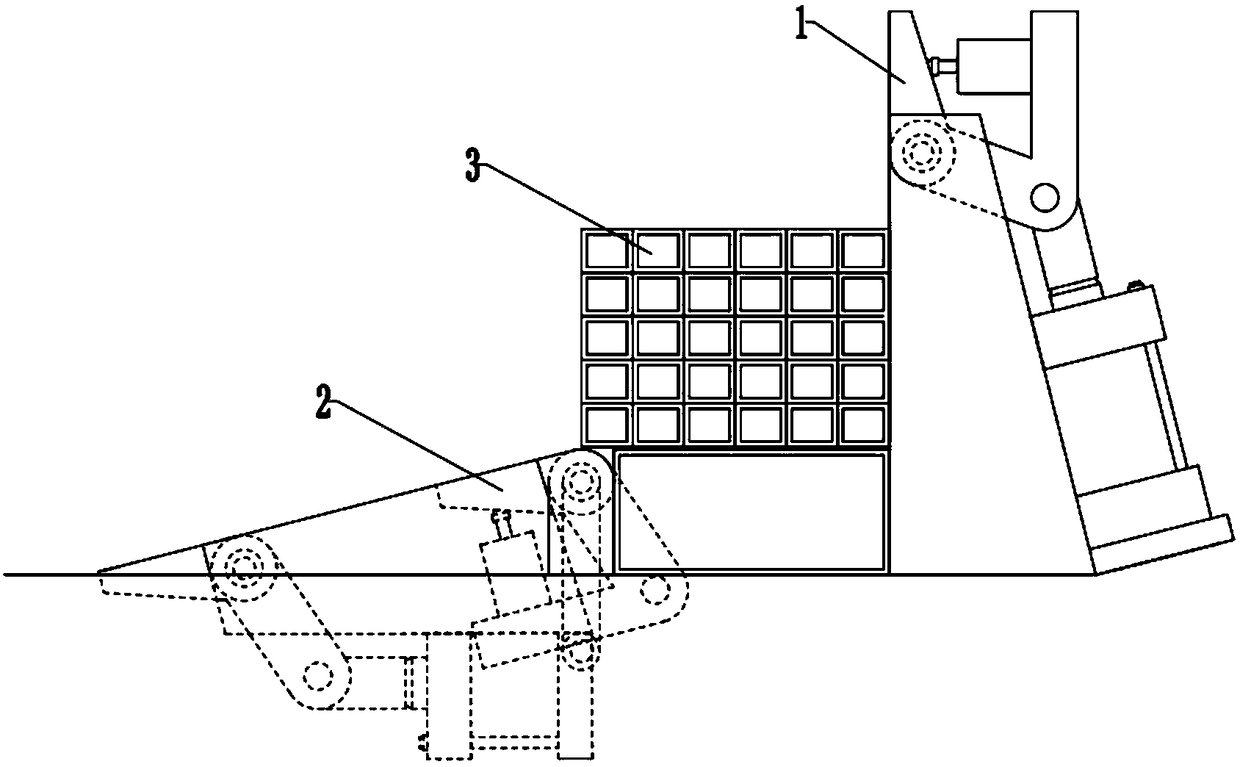

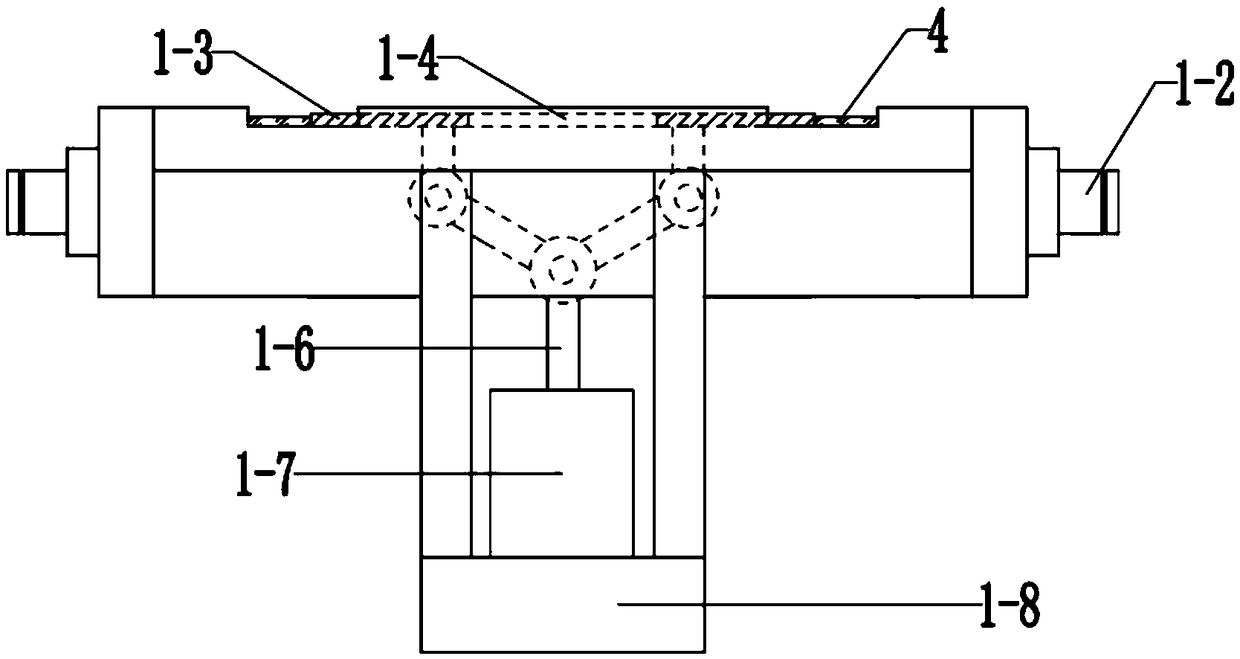

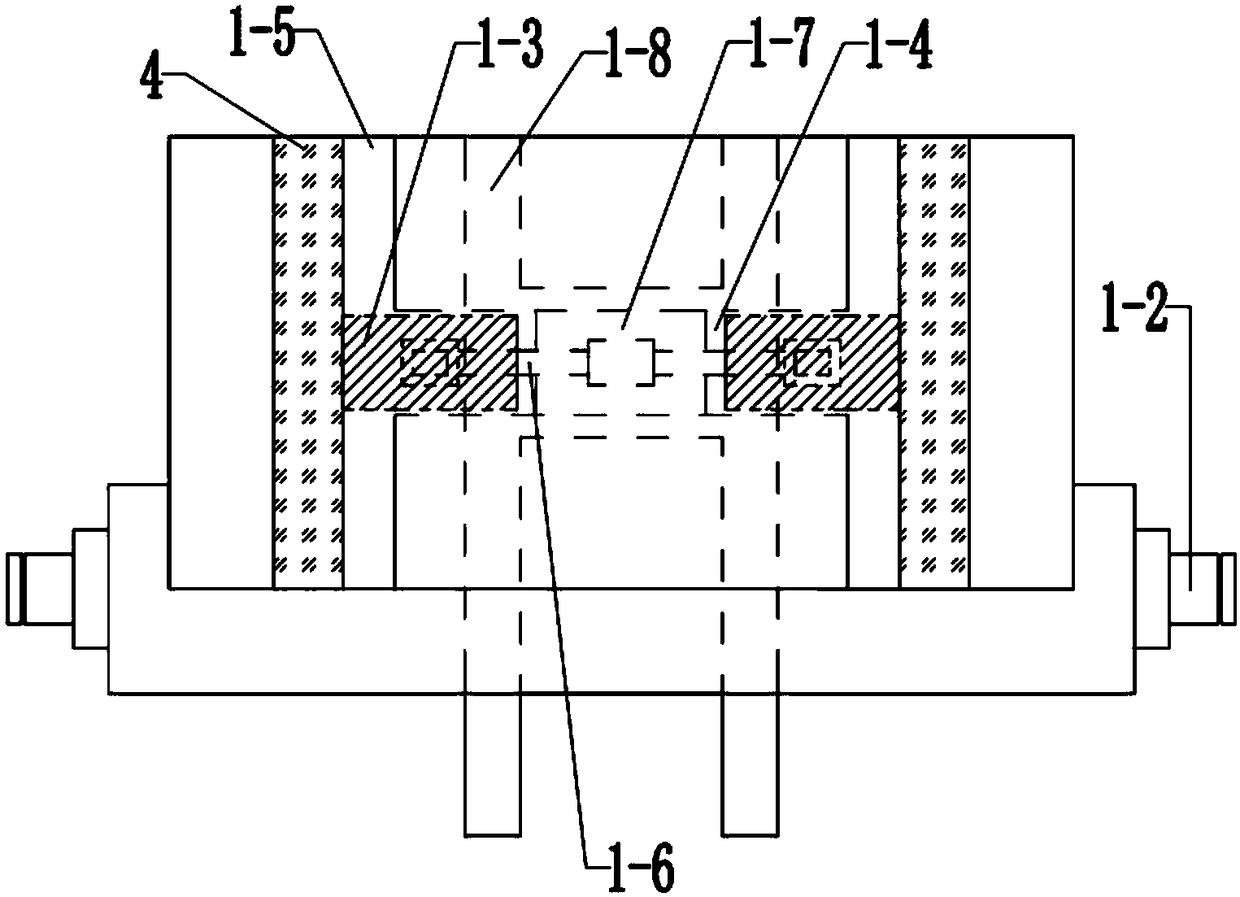

[0032] Embodiment: the compression device of square tube baler (seeing Figure 1-Figure 7 ), including pressing plate A 1 and pressing plate B 2, said pressing plate A 1 includes pressing plate A body 1-1 and shaft A 1-2, the middle part of said pressing plate A body 1-1 is assembled with shaft A 1-2, said The pressing plate B 2 includes the pressing plate B body 2-1 and the shaft B 2-2, the middle part of the pressing plate B body 2-1 is assembled with the shaft B 2-2; it is characterized in that the pressing plate A 1 also includes a slider A 1- 3 and slider A pushing structure, the pressing plate B 2 also includes a sliding block B2-3 and a sliding block B pushing structure; the working surface of the head of the pressing plate A body 1-1 is set for positioning the rectangular tube packing The groove A 1-5 with 4, the direction of the groove A 1-5 is along the direction of the rectangular tube packing belt 4, and the working surface of the head of the pressure plate B body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com