Method for improving hydrophilicity of cocoon shells through low-temperature contact steaming of dried cocoons

A hydrophilic, touch-steaming technology, applied in the chemical post-treatment of fibers, textiles and papermaking, fiber processing, etc., can solve the problems of uneven touch-steaming, uneven moisture absorption, molecular weight reduction, etc., to achieve uniform moisture absorption, improve The effect of infiltration penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

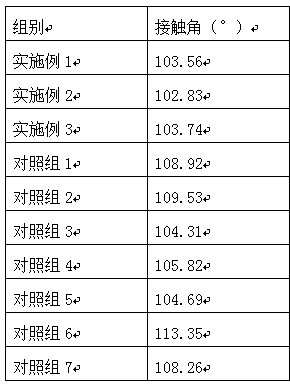

Examples

Embodiment 1

[0016] A method for improving the hydrophilicity of the cocoon layer by steaming dry cocoons at low temperature, comprising the following content:

[0017] (1) Soak the selected cocoons in the finishing solution for 50 minutes at a temperature of 40°C. After completion, store them in the dark for 1.5 hours at a temperature of 5°C;

[0018] The finishing liquid includes the following raw materials in parts by weight: 1 part of sodium fatty alcohol polyoxyethylene ether carboxylate, 2.9 parts of glycolic acid, 4 parts of ginger powder extract, 3.2 parts of vitamin B, 35 parts of ethanol, and 55 parts of water;

[0019] (2) Put the treated cocoons into a cloth bag, put them into a saturated steam touch steamer, set the touch steam temperature to 80°C, keep for 8 minutes, adjust the touch steam temperature to 50°C, and keep it for 35 minutes. .

[0020] Wherein, the step (1) soaking process also includes ultrasonic treatment, and the ultrasonic frequency is 24kHz.

[0021] Where...

Embodiment 2

[0027] A method for improving the hydrophilicity of the cocoon layer by steaming dry cocoons at low temperature, comprising the following content:

[0028] (1) Soak the selected cocoons in the finishing solution for 60 minutes at a temperature of 35°C. After completion, store them in the dark for 1 hour at a temperature of 6°C;

[0029] The finishing solution includes the following raw materials in parts by weight: 0.8 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, 3.4 parts of glycolic acid, 5 parts of ginger powder extract, 2.8 parts of vitamin B, 40 parts of ethanol, and 60 parts of water;

[0030] (2) Put the treated cocoons into a cloth bag, put them into a saturated steam touch steamer, set the touch steam temperature to 80°C, keep it for 10 minutes, then adjust the touch steam temperature to 50°C, and keep it for 40 minutes. .

[0031] Wherein, the step (1) soaking process also includes ultrasonic treatment, and the ultrasonic frequency is 22kHz.

[...

Embodiment 3

[0038] A method for improving the hydrophilicity of the cocoon layer by steaming dry cocoons at low temperature, comprising the following content:

[0039] (1) Soak the selected cocoons in the finishing solution for 40 minutes at a temperature of 45°C. After completion, store them in the dark for 2 hours at a temperature of 4°C;

[0040] The finishing solution includes the following raw materials in parts by weight: 1.2 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, 2.4 parts of glycolic acid, 3 parts of ginger powder extract, 3.6 parts of vitamin B, 30 parts of ethanol, and 50 parts of water;

[0041] (2) Put the treated cocoons into a cloth bag, put them into a saturated steam touch steamer, set the touch steam temperature to 80°C, keep it for 5 minutes, adjust the touch steam temperature to 50°C, and keep it for 30 minutes to get the product .

[0042] Wherein, the step (1) soaking process also includes ultrasonic treatment, and the ultrasonic frequency i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com