Continuous prefabricated safety fence connecting method

A connection method and safety guardrail technology, which can be applied to road safety devices, bridge parts, roads, etc., can solve the problems of lack of interchangeability and multiple uses, cumbersome installation, high cost, etc., and achieve reliable protection, firm and reliable connection, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

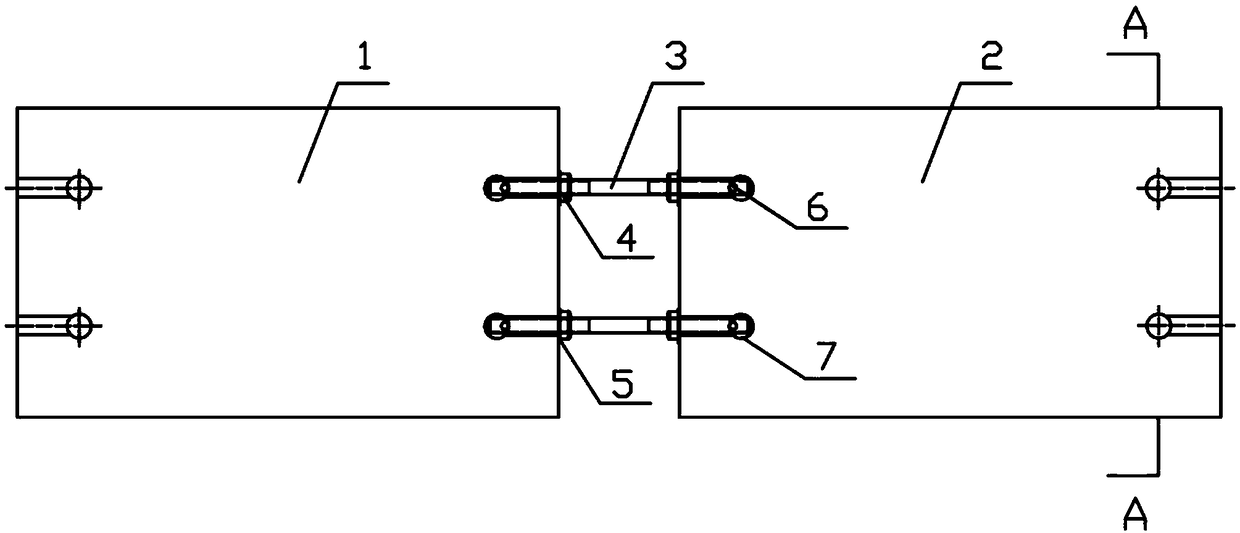

[0032] Such as figure 1 and Figure 7 As shown, a continuous prefabricated safety guardrail connection method described in the present invention,

[0033] Include the following steps:

[0034] 1) Lay out the line at the position where the guardrail needs to be installed as the starting position;

[0035] 2) Hoist the section N guardrail 1 to the starting position first;

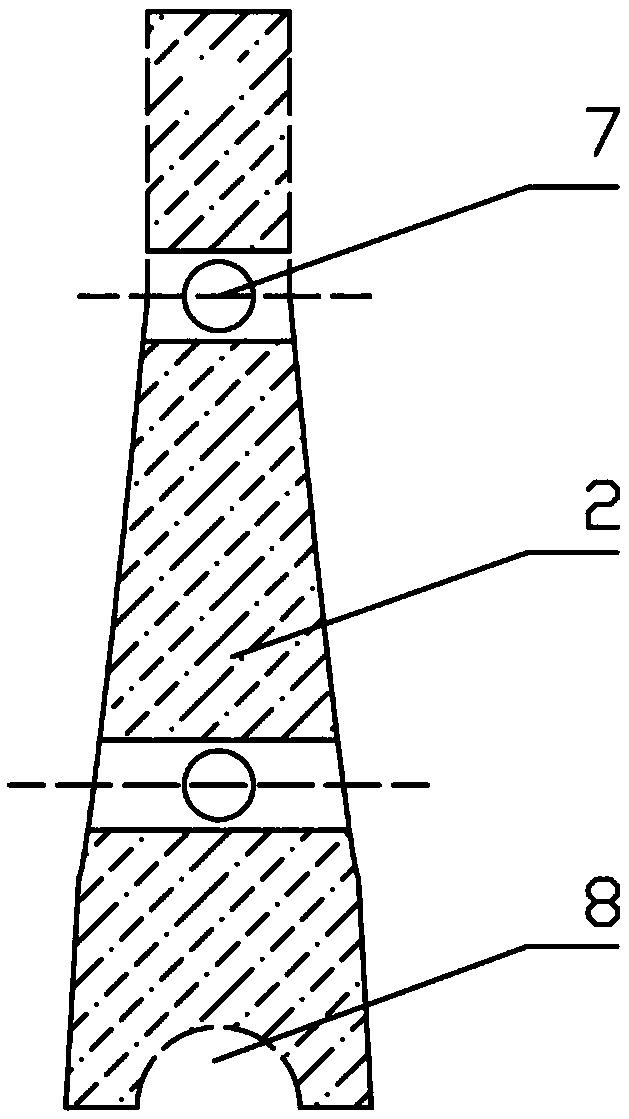

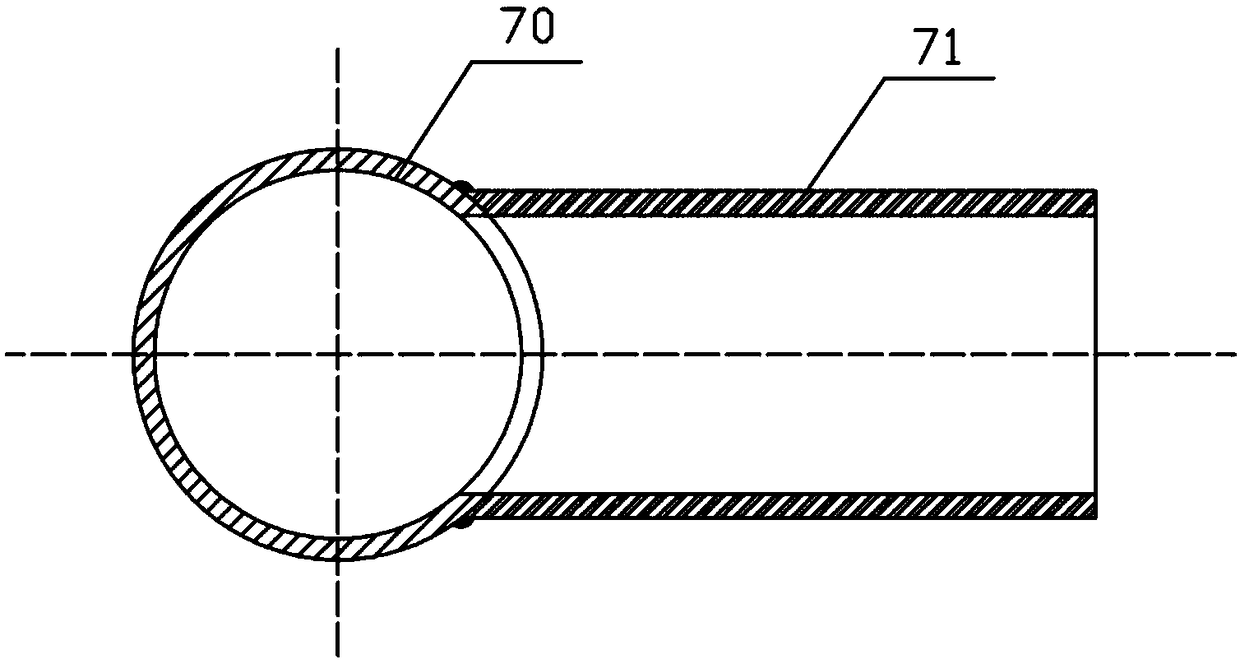

[0036] 3) Put the nut assembly on the two ends of the double-ended screw rod 3 respectively, and insert one end into the embedded part 7 of the guardrail embedded in the guardrail 1 of the Nth section;

[0037] 4) Fix the end of the double-ended screw mandrel 3 in the guardrail embedded part 7 on the Nth section guardrail 1 through the screw mandrel pin 6;

[0038] 5) Appropriately tighten the nut assembly at the end of guardrail 1 of Section N, but not too tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com