Prefabricated stair temporary support device and application and construction methods thereof

A temporary support and stair technology, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, construction, etc., can solve problems such as difficulty in support positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

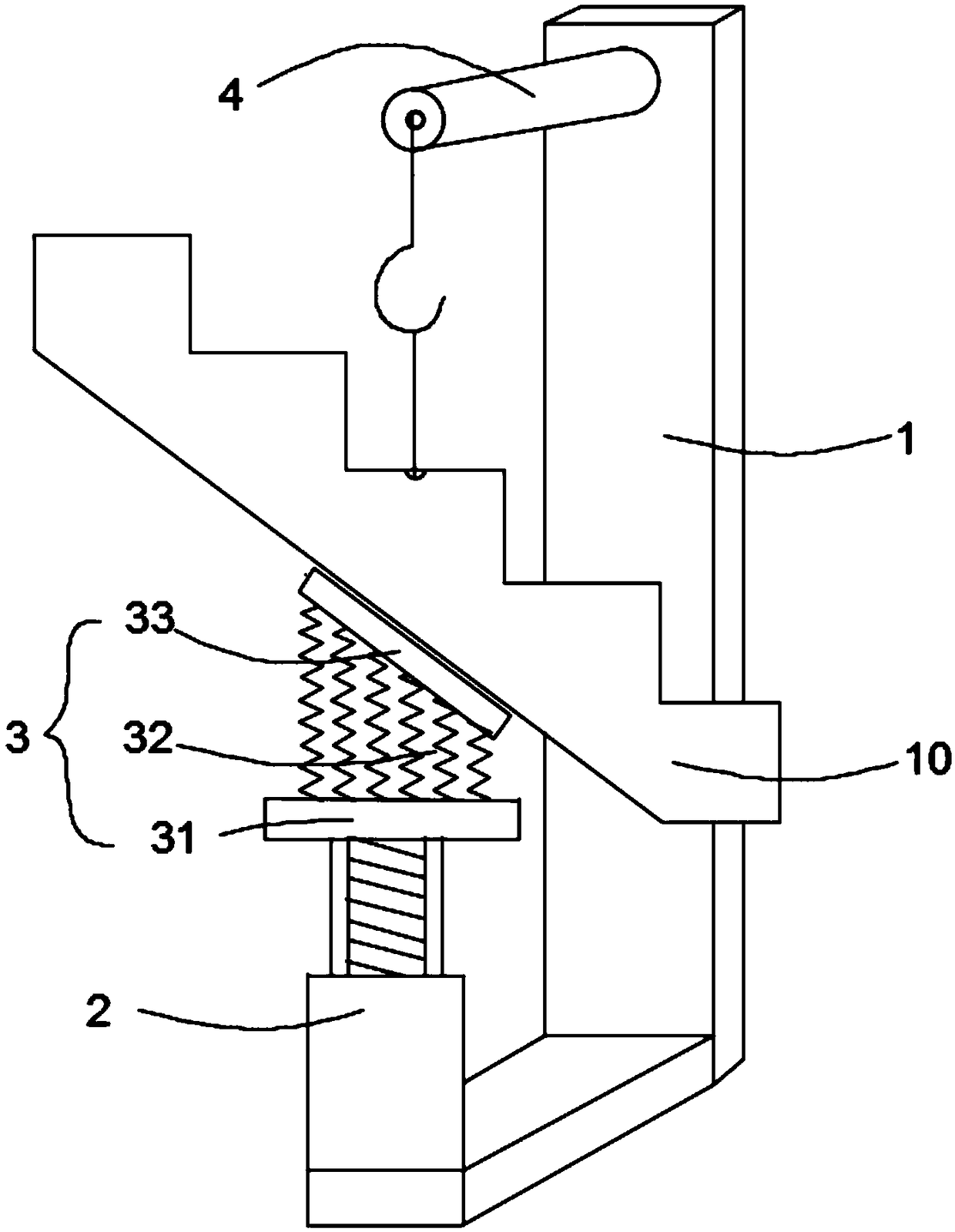

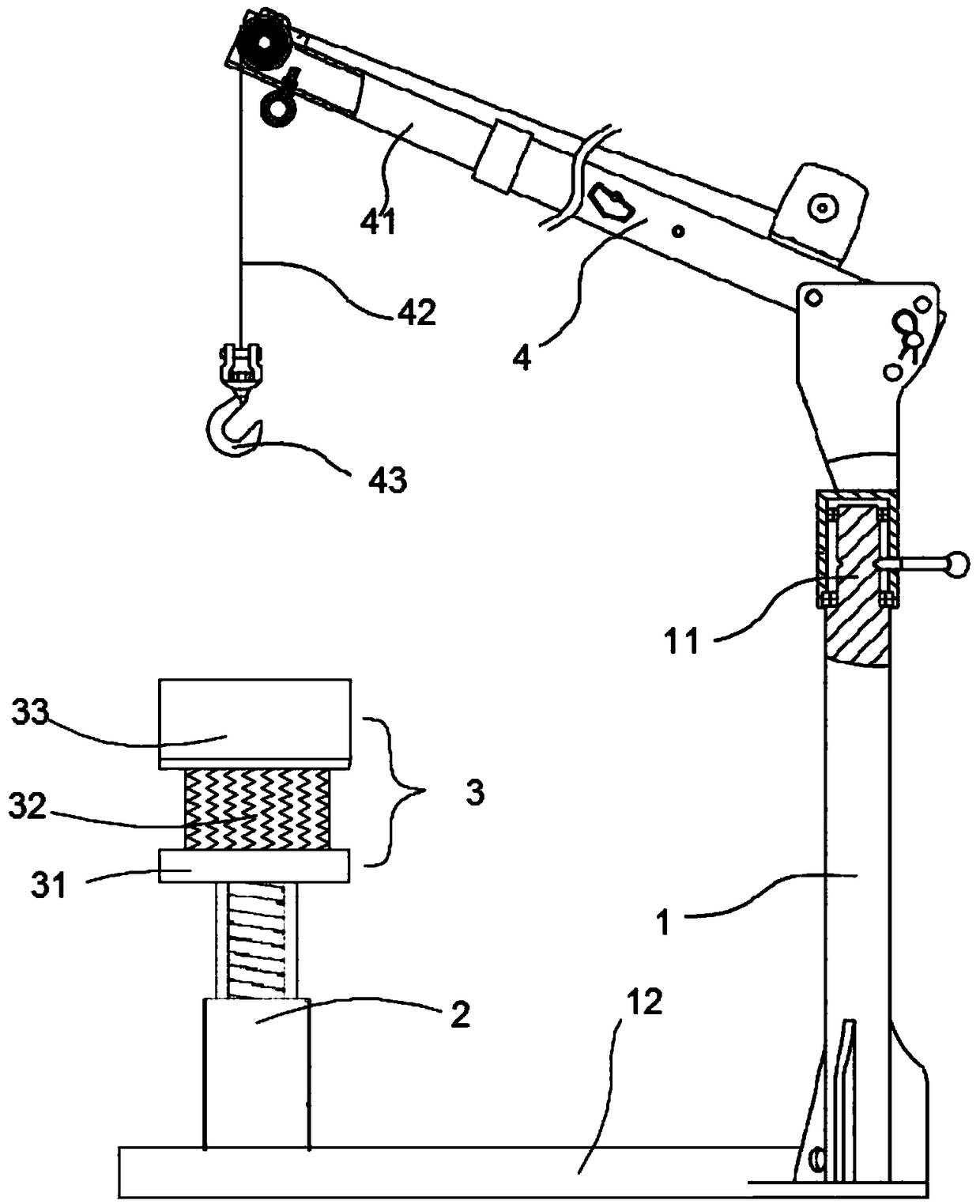

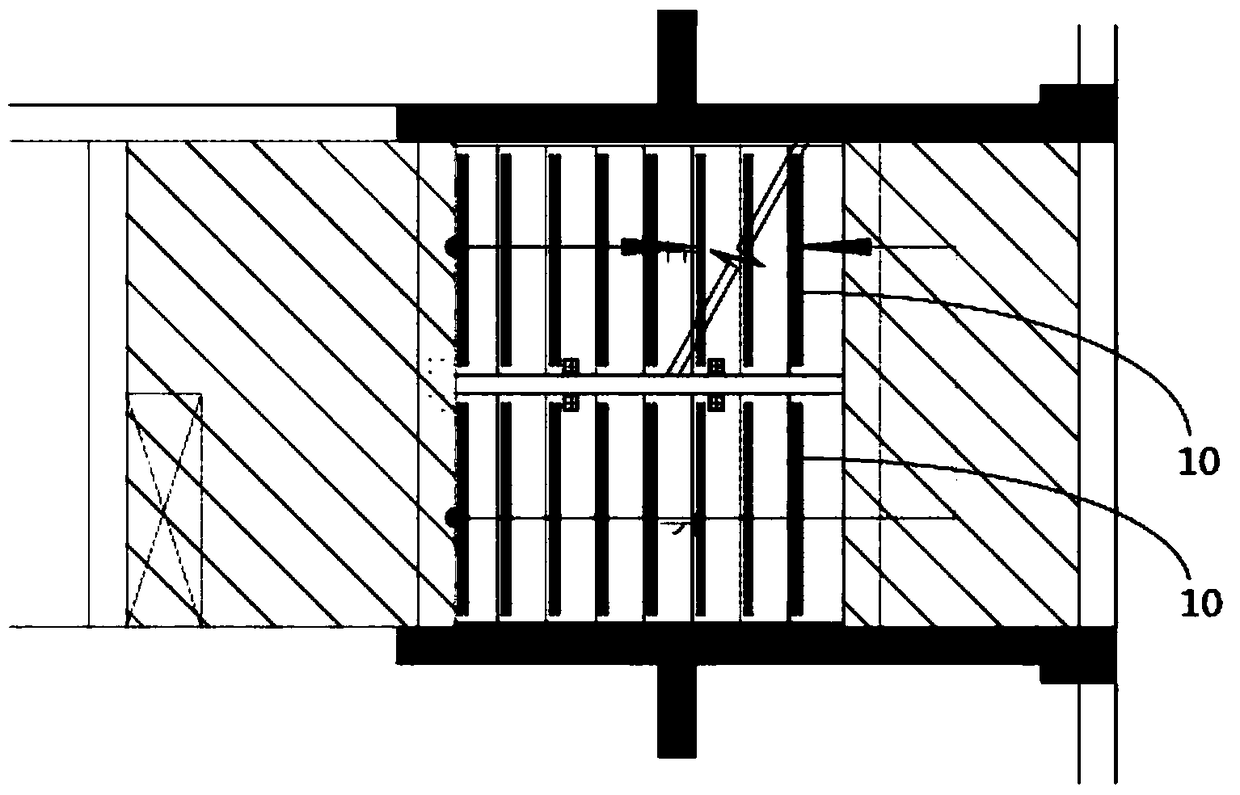

[0043] Such as figure 1 As shown, the prefabricated stair temporary support device of an embodiment includes a main body 1, a lifting part 2, a support part 3, and a suspension part 4; the main body 1 is fixed on the scaffold by a fixing member; the lifting part 2 is arranged on the The extension part 12 below the main body part 1; the support part 3 is located between the lifting part 2 and the prefabricated staircase; the suspension part 4 is arranged on the upper part of the main body part. The prefabricated staircase 10 is supported through the cooperation of the support part 3 and the suspension part 4 .

[0044] as attached figure 2 As shown, the support part 3 includes a first support part 31, a second support part 32 and a third support part 33 connected in sequence, the first support part 31 is connected with the lifting part 2, and the second support part One end of the member 32 is connected to the first support member 31, and the other end is connected to the th...

Embodiment 2

[0057] In this embodiment, a bar-shaped slider is provided on the outside of the third support member 33, and a chute matching the slider is fixed on the outside of the first support member; The upper end of the shaped slider is hinged with the third support member 33, and the lower end is inserted into the chute. The first switch and the second switch are arranged at intervals of a certain distance in the chute; when the third support member compresses the second support member downward, the slider moves along the slide The slot slides to actuate the first switch and the second switch in sequence. The first switch and the second switch may be buttons arranged on one side inside the chute, and when the slider passes by, the buttons are pressed to send a switch signal. Of course, the first switch and the second switch may also be switches in other forms that can be mechanically or inductively triggered by the slider, which will not be detailed here.

[0058] One end of the fi...

Embodiment 3

[0062] In this embodiment, the difference from Embodiment 1 is that the swing arm 41 of the suspension part 4 is non-stretchable, and a pulley structure is provided on the suspension arm 41, and the lifting and lowering of the hook is adjusted by a plurality of cables. The principle of the movement along the direction of the swing arm 41 is the same as that of the hook control of the hoisting machinery in the prior art, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com