Single-cavity spring brake chamber for energy storage air break

A brake chamber, single-chamber technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of increased cost burden, waste of diaphragm cavity, etc., and achieve the effect of saving production and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

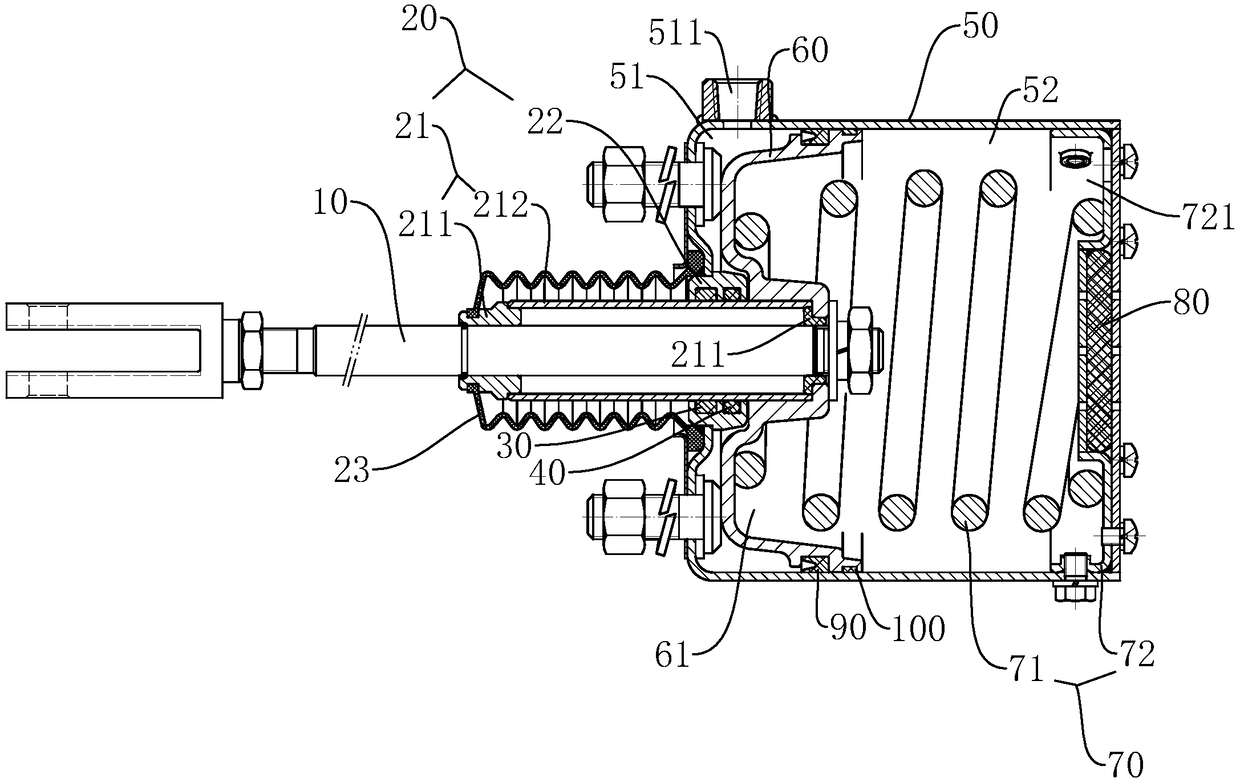

[0012] combine figure 1 The single-chamber spring brake chamber of the air cut-off brake of the present invention is further described.

[0013] A single-chamber spring brake chamber for an air cut-off brake, comprising a cylinder body 50 , a push rod disc 60 , a push rod 10 and a spring assembly 70 . The push rod plate 60 is arranged in the cylinder body 50, and can move along the axial direction of the cylinder body 50, and divides the inside of the cylinder body 50 into an air chamber 51 and a spring chamber 52, and the air chamber 51 and the spring chamber 52 Arranged along the axial direction of the cylinder body 50; a sealing ring 90 and a nylon ring 100 are arranged between the edge position of the push rod disc 60 and the inner wall of the cylinder body 50, and the sealing ring 90 can seal the air cavity 51 and the spring cavity 52 to avoid The air pressure in the air chamber 51 is lost into the spring chamber 52, resulting in air pressure loss. The air cavity 51 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com