Manufacturing method of sliding bracket for steam pipeline, and sliding bracket

A steam pipeline and sliding support technology, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of low efficiency and complex production of sliding supports, and achieve the effects of simple production, reduced construction period and improved production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

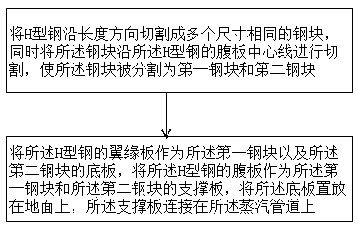

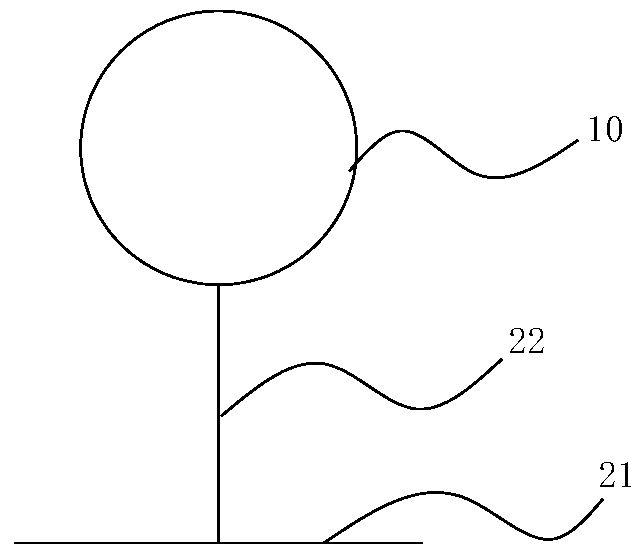

[0020] Such as figure 1 and figure 2 As shown, the present embodiment provides a method for manufacturing a sliding bracket for a steam pipe, which is placed under the steam pipe 10, and includes the following steps: Step S1: Cut the H-shaped steel into multiple steel blocks of the same size along the length direction, and at the same time Cutting the steel block along the web centerline of the H-shaped steel, so that the steel block is divided into a first steel block and a second steel block; Step S2: using the flange plate of the H-shaped steel as the The bottom plate 21 of the first steel block and the second steel block, the web of the H-shaped steel is used as the support plate 22 of the first steel block and the second steel block, and the bottom plate 21 is placed On the ground, the support plate 22 is connected to the steam pipe 10 .

[0021] The steam pipeline sliding support in this embodiment is placed under the steam pipeline 10, including the following steps: ...

Embodiment 2

[0025] This embodiment provides a sliding bracket, which is manufactured using the manufacturing method described in Embodiment 1, such as figure 2 As shown, it includes a bottom plate 21 and a support plate 22 above the bottom plate 21 , wherein the bottom plate 21 and the support plate 22 are integrally formed, and the support plate 22 is fixed on the steam pipe 10 .

[0026] The sliding bracket in this embodiment includes a bottom plate 21 and a support plate 22 above the bottom plate 21, wherein the bottom plate 21 and the support plate 22 are integrally formed, and the support plate 22 is fixed on the steam pipe 10 In fact, due to the simple production, it can greatly improve the installation efficiency, thereby helping to reduce the construction period of the entire project.

[0027] The bottom plate 21 is fixed on the embedded parts, and the flatness can be ensured by the embedded parts. The height direction of the support plate 22 is perpendicular to the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com