Heavy-duty car dual-drive tandem testbed

A technology for double-drive axles and heavy-duty vehicles, which is applied in vehicle testing, machine/structural component testing, and measuring devices. Problems such as the aggravation of spring force and mass can achieve the effect of increasing the cost of test equipment and occupying space, reducing the difficulty of installation and adjustment of test pieces, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

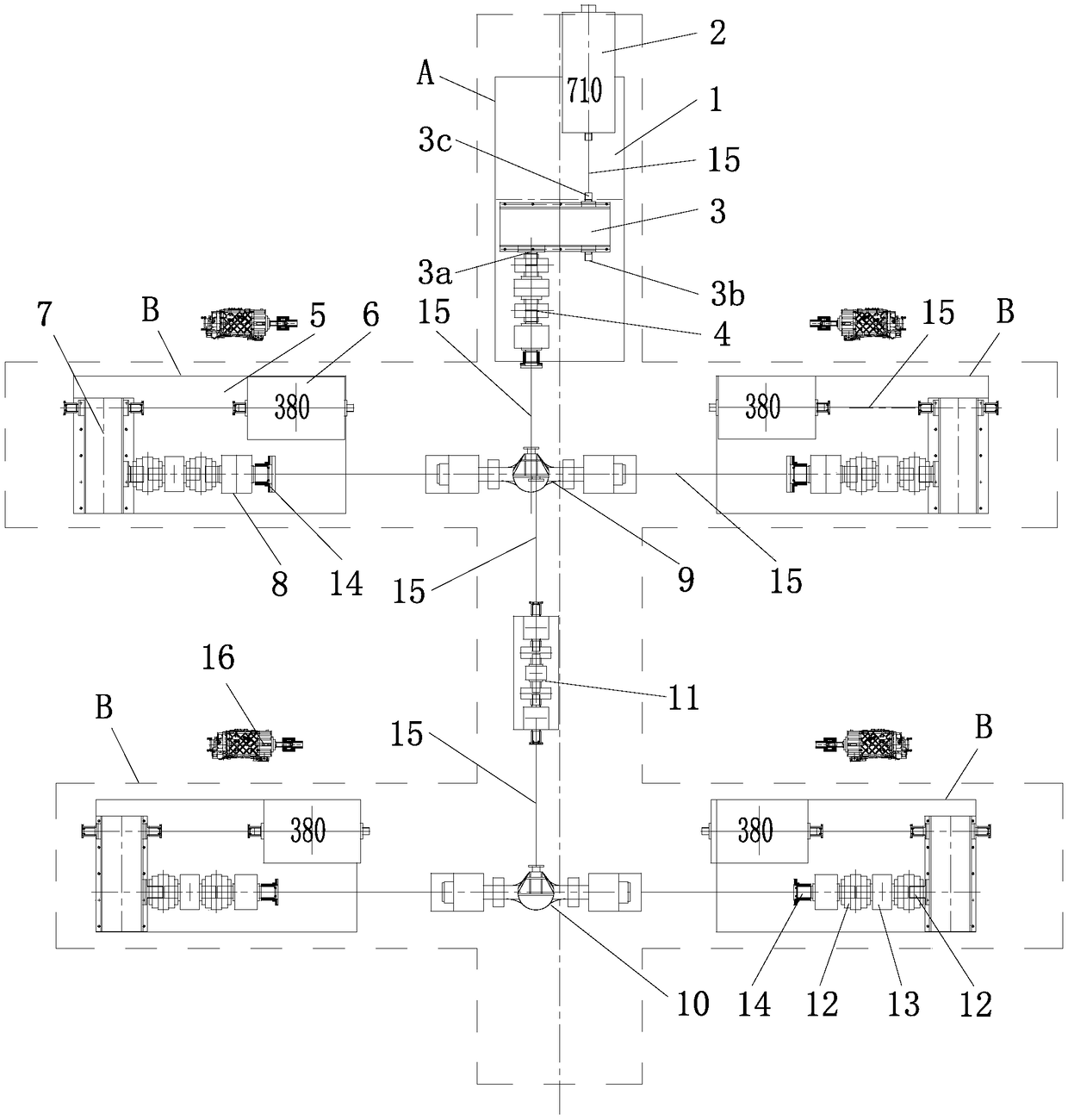

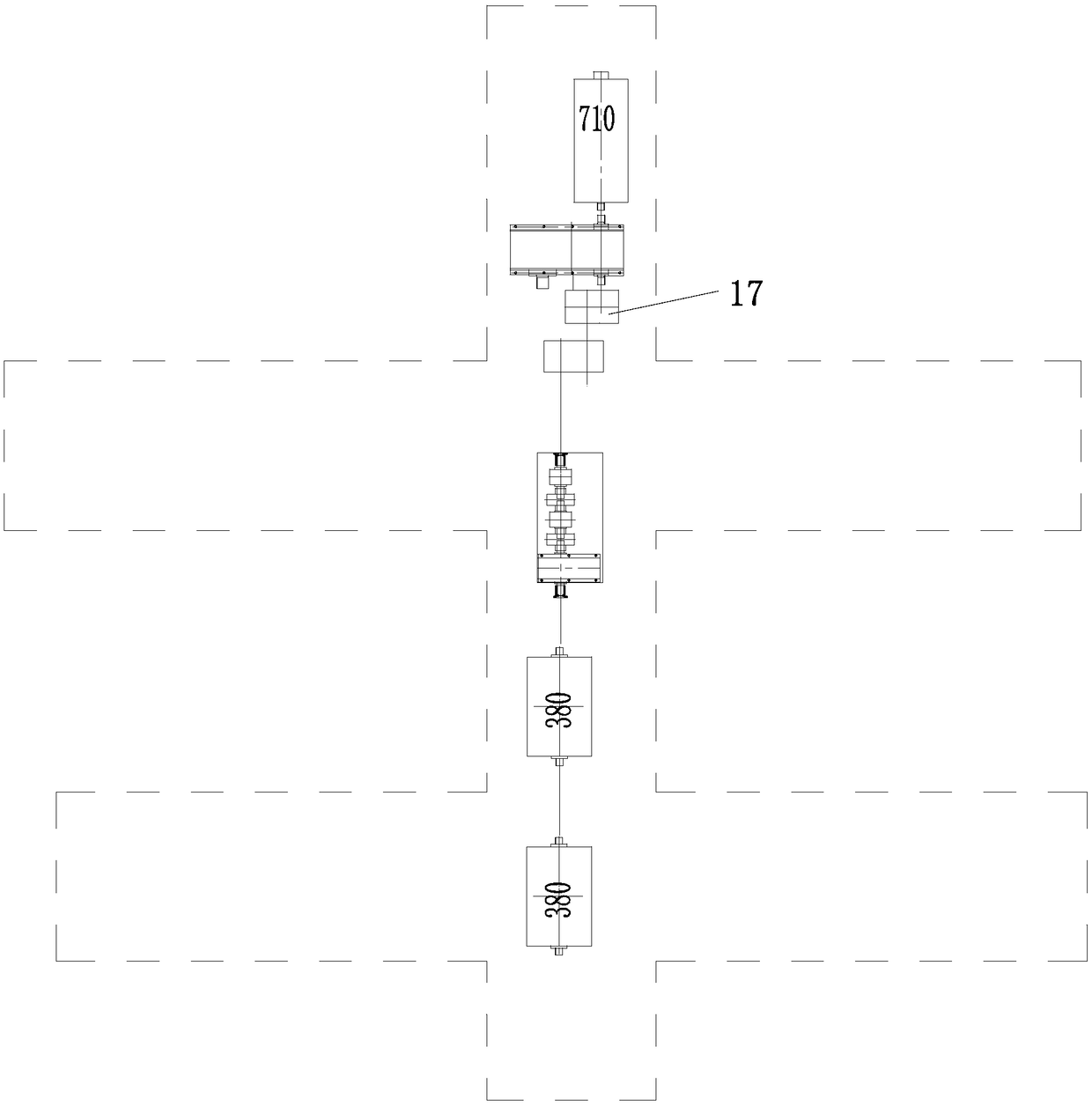

[0019] like figure 1 As shown, a heavy-duty vehicle double drive axle test bench is mainly composed of an integrated driving head A and four integrated loading heads B.

[0020] The integrated drive head A is equipped with a drive head base 1, on which a variable frequency drive motor 2, a deceleration-up-torque transmission box 3 and a system power input testing mechanism 4 are sequentially installed in series. The integrated drive head A is used to simulate the power drive system of heavy vehicles. The system power input testing mechanism 4 is used to test the system power input.

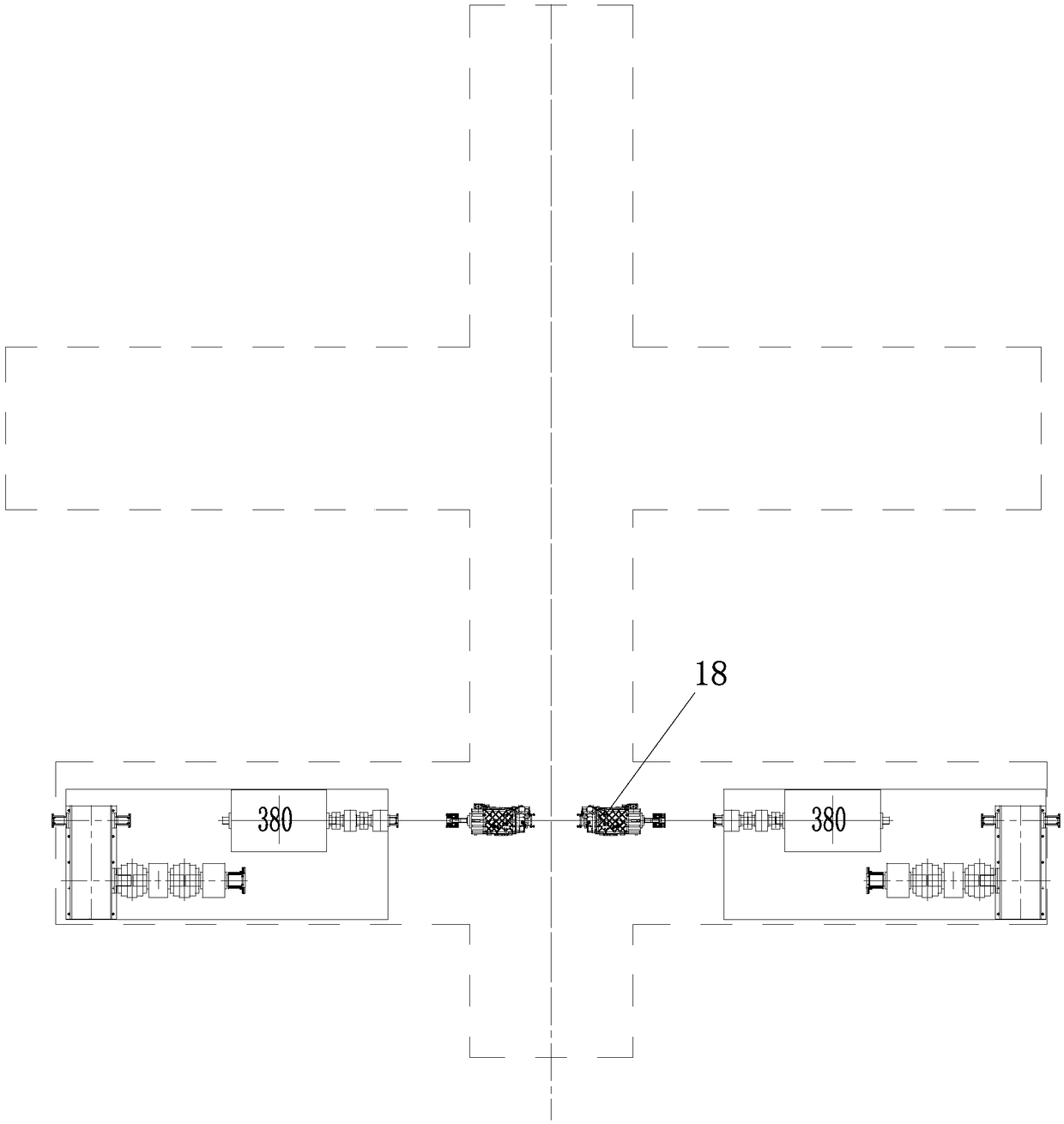

[0021] The integrated loading head B is equipped with a loading head base 5, on which a frequency conversion loading motor 6, a speed-up and torque-down transmission box 7 and a bridge unilateral output power testing mechanism 8 are installed in series. The integrated load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com