Powdery material sampling device

A sampling device and powder technology, applied in the direction of sampling devices, etc., can solve problems such as easy to be affected by moisture, easy to generate dust samples, etc., to achieve the effects of alleviating moisture and agglomeration, reducing waste, and widening industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

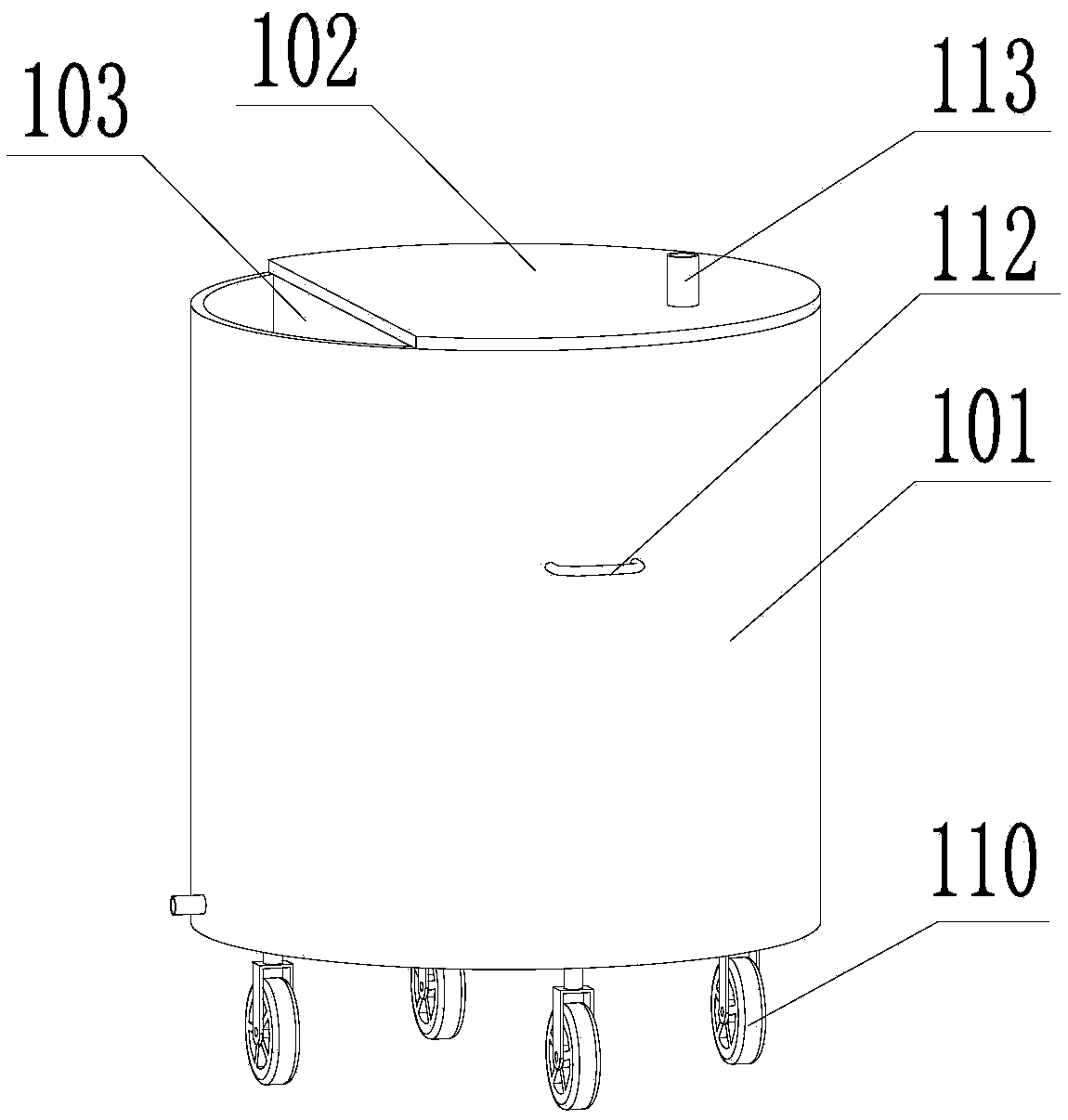

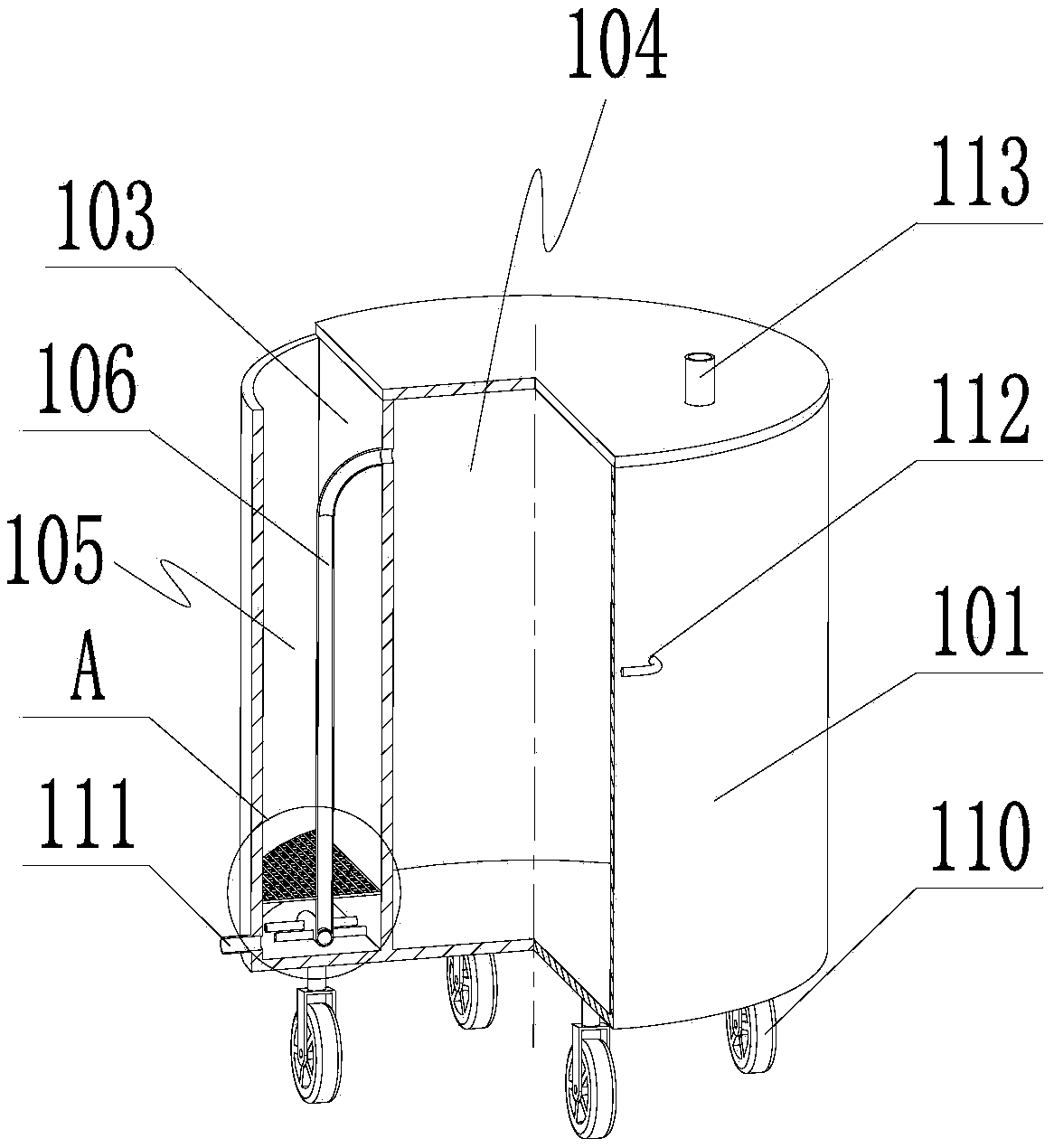

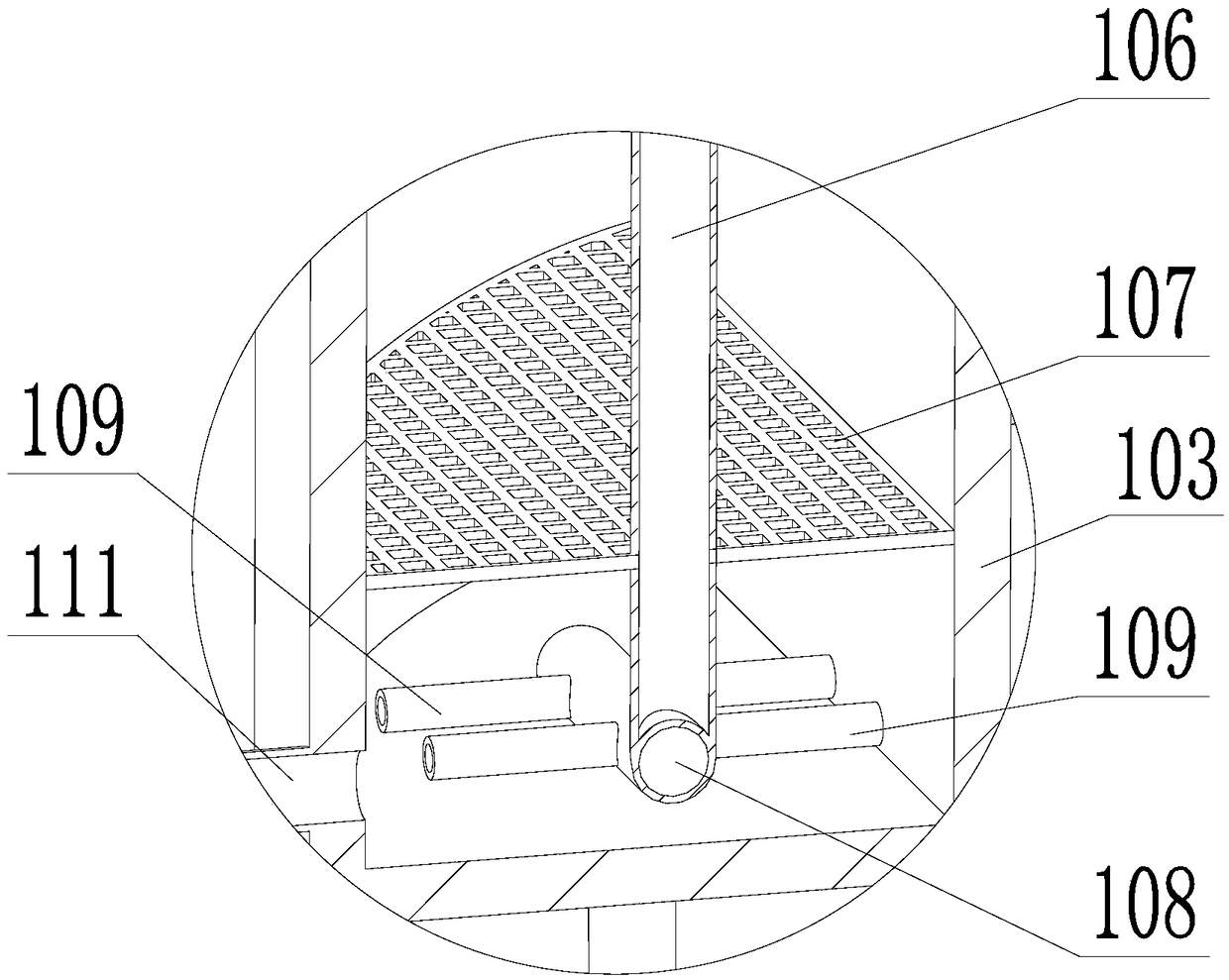

[0029] see Figure 1 to Figure 3 As shown, the present embodiment provides a powder sampling device, including a barrel body 101 and a barrel cover 102, the barrel body 101 is sealed with the barrel cover 102, and a partition 103 is arranged inside the barrel body 101, and the partition plate 103 will The inner space of barrel body 101 is divided into powder holding chamber 104 and liquid holding chamber 105, and partition 103 is provided with through hole; For containing the liquid, the inside of the liquid holding chamber 105 is provided with a conduit 106 and a defoaming net 107, the conduit 106 has a first end and a second end, the first end is located above the liquid level of the liquid, and the first end communicates with the through hole, The second end is located below the liquid surface; the defoaming net 107 is sheathed on the conduit 106, and the defoaming net 107 is located below the liquid surface.

[0030] Based on this structure, the powder sampling device pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com