Backlight module and manufacturing method thereof

A technology for a backlight module and a manufacturing method, applied in the field of backlight modules and their manufacturing, can solve the problems such as the inability to effectively reduce the thickness, the inability of the luminous keyboard to meet the design requirements of light and thin, the inability to reduce the thickness of the light source circuit board 323, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

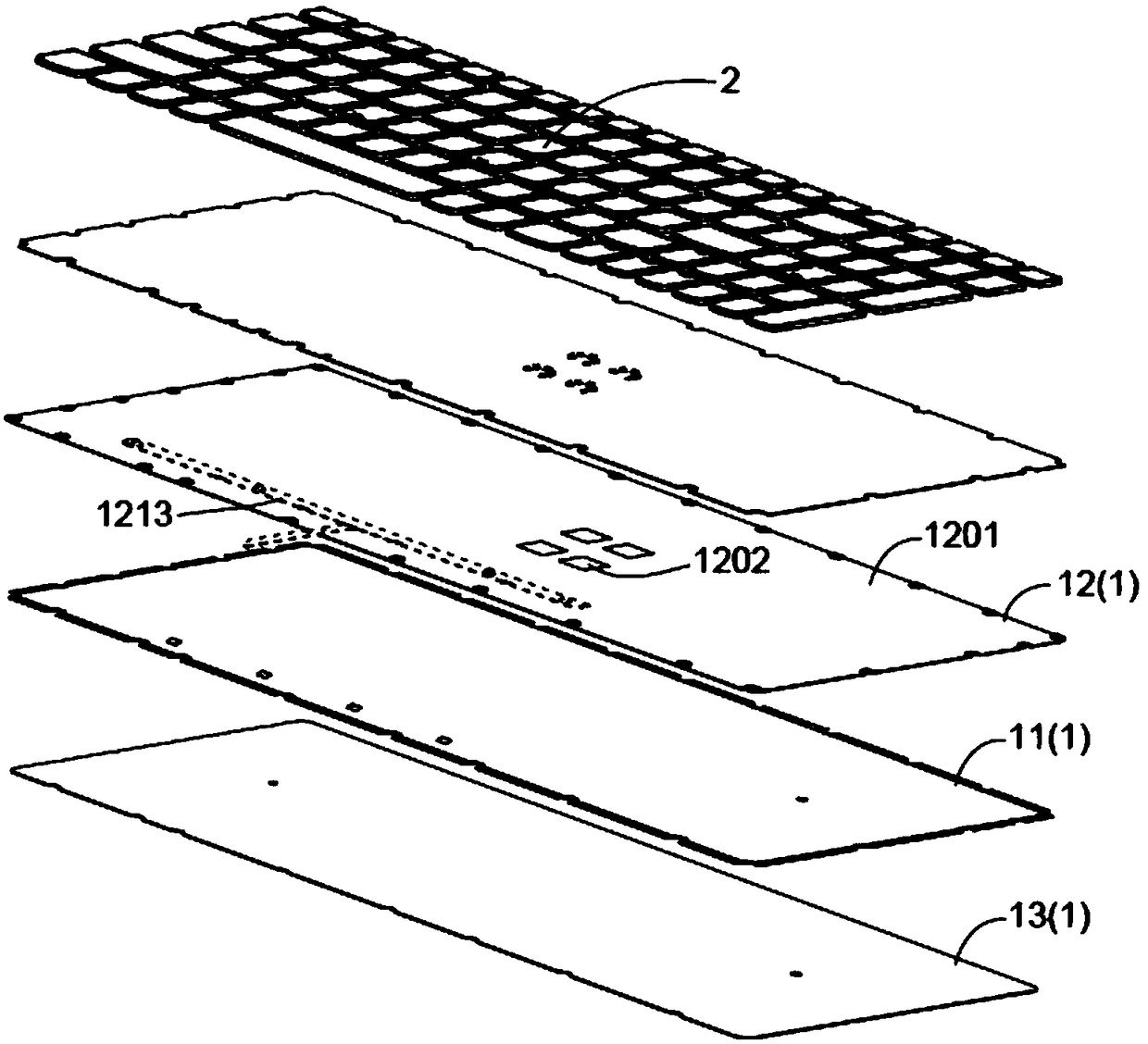

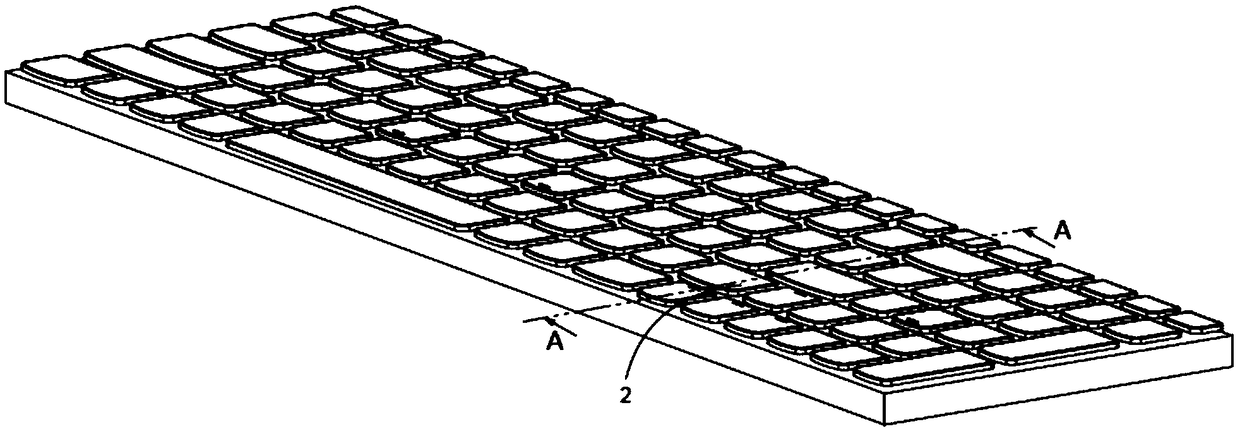

[0033] Please also refer to Figure 2 to Figure 4 , wherein, as shown in the drawings referred to in the left column, the backlight module 1 of the first embodiment is used to provide backlight BL for illuminating a plurality of keycaps 2, wherein there are keycaps between the plurality of keycaps gap. The backlight module 1 of this embodiment includes a light guide plate 11 , a light shielding plate 12 and a reflective plate 13 . The light guide plate 11 is located under the multiple keycaps 2, providing total reflection of the light R inside it, and passing from one end to the other end, and the side of the light guide plate 11 away from the multiple keycaps 2 has multiple scattering structures 111, so The plurality of scattering structures 111 are located under one of the plurality of keycaps 2 respectively, such as concave-convex microstructures or scattering dots, and the concave-convex microstructures may be V-groove structures. In this embodiment, the scattering struc...

no. 2 example

[0044] Please also refer to Figure 5 , wherein, as shown in the drawings referred to in the left column, the biggest difference between the second embodiment and the first embodiment is that the scattering structure 111 of the light guide plate 11 of the backlight module of the second embodiment is arranged on the approach key of the light guide plate 11 The first side of the cap 2 is located below the keycap 2 , and the second side of the light guide plate 11 facing away from the keycap 2 is printed with reflective ink to form a reflective layer 112 of the light guide plate. The position of the scattering structure 111 on the light guide plate 11 destroys the total reflection of the light R in the light guide plate 11, and then scatters the light R in the light guide plate 11, so that the light R can be transmitted toward the keycap 2 and become a backlight BL, so that The light source required for the keycap 2 to emit light is provided. The reflective layer 13 of the light...

no. 3 example

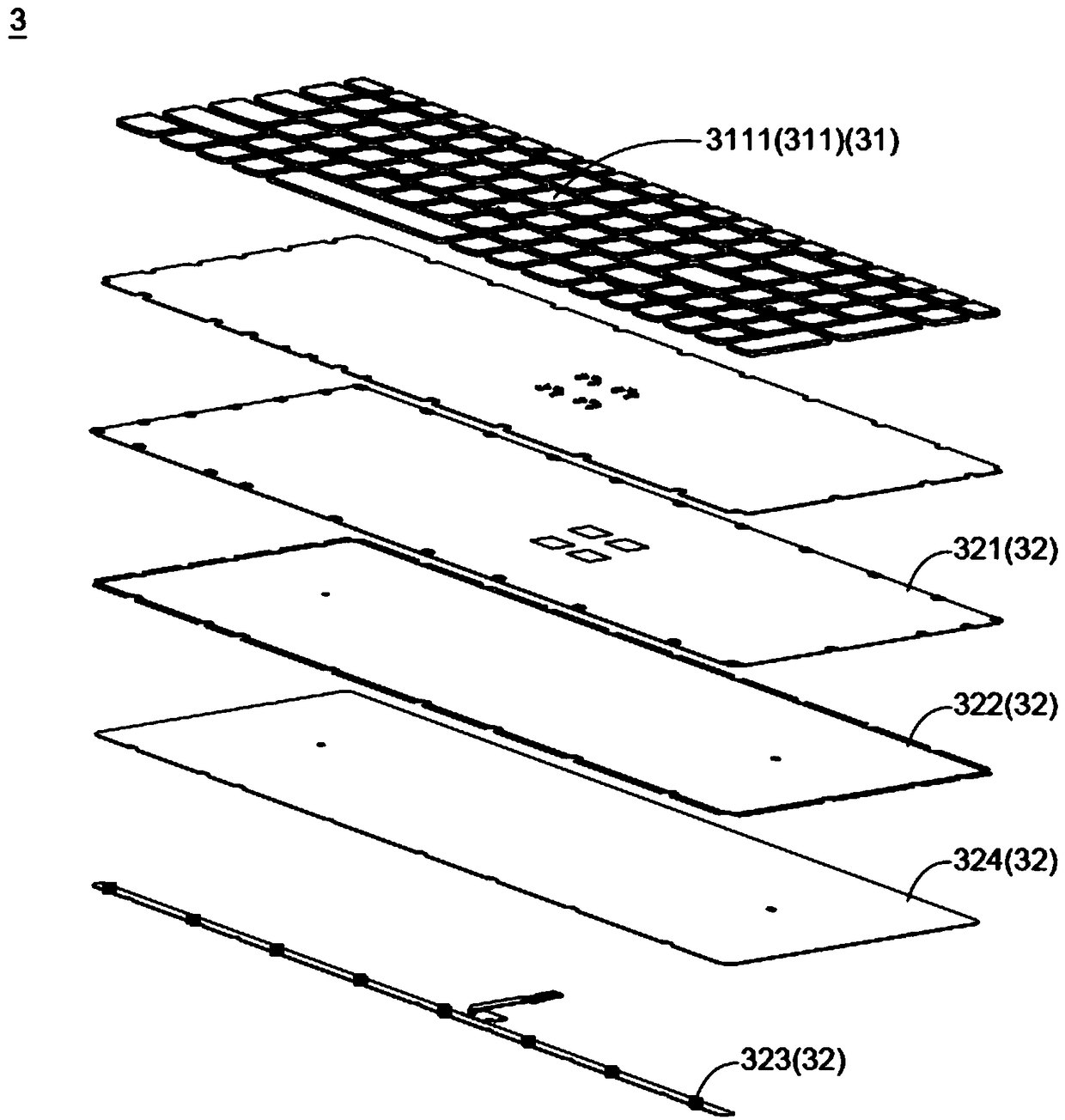

[0047] Please also refer to Figure 6 , wherein, as shown in the drawings referred to in the left column, the reflection plate 13 is arranged on the side of the light guide plate 11 away from the light shielding plate 12, so as to reflect the light R transmitted in the direction away from the light shielding plate 12 and leaving the light guide plate 11, so that The light R returns to the inside of the light guide plate 11 and passes toward the light shielding plate 12 , and the reflection plate can reflect the light R1 leaving the light guide plate 11 back into the light guide plate 11 . The biggest difference between the third embodiment and the first embodiment is that the reflector 13 is provided with a reflector light-emitting element 131 adjacent to the light guide plate 11 . The reflector light-emitting element 131 has a light-emitting surface and can provide light R to the light guide plate 11 .

[0048] To sum up, since the light source of the backlight module of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com