In-pipe electric wire drawing device for building intelligent installation engineering

A technology for installation engineering and pulling device, applied in the field of electric power, can solve the problems of intricate and knotted steel wires, and achieve the effect of avoiding intricate smashing, ensuring cleanliness, and avoiding knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

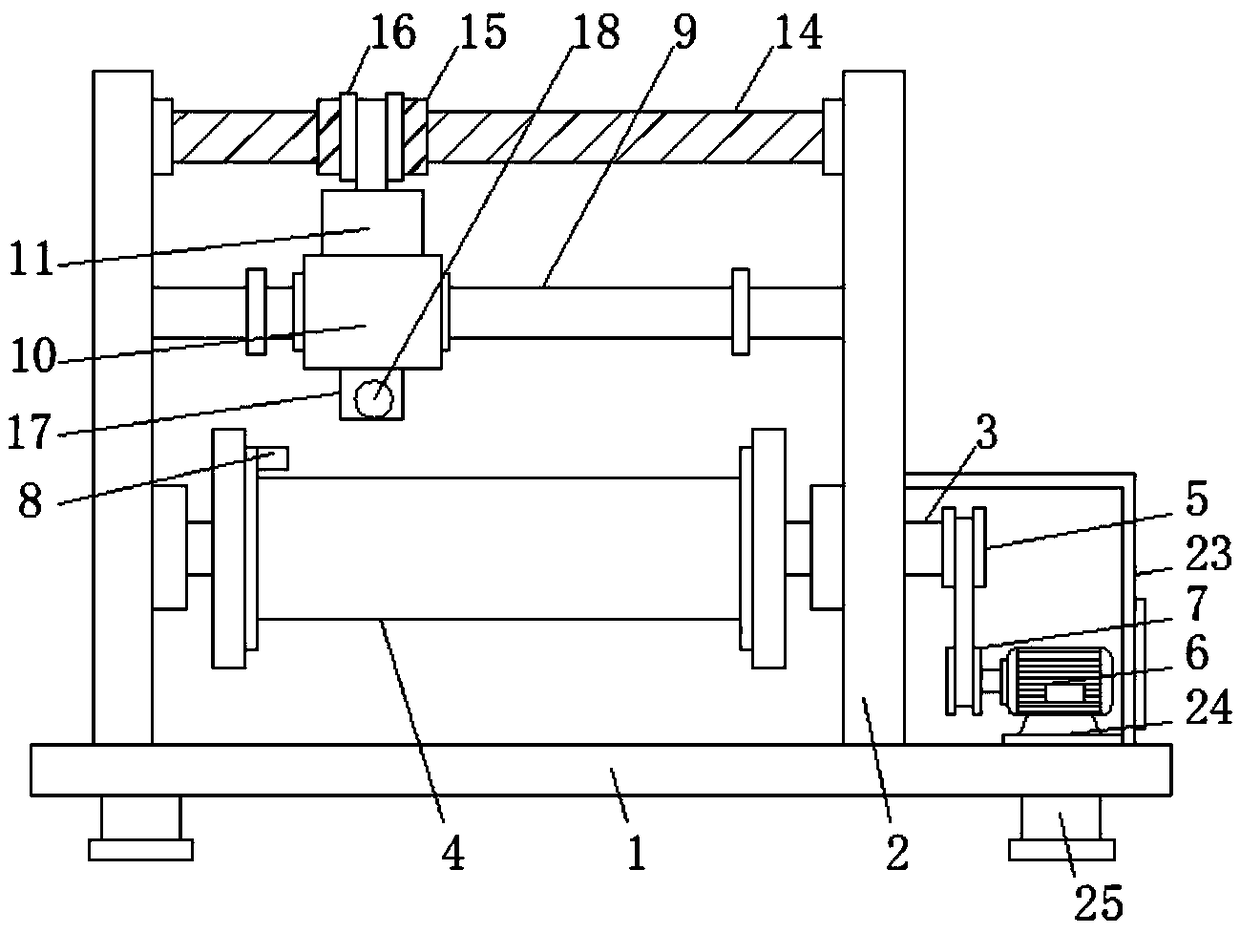

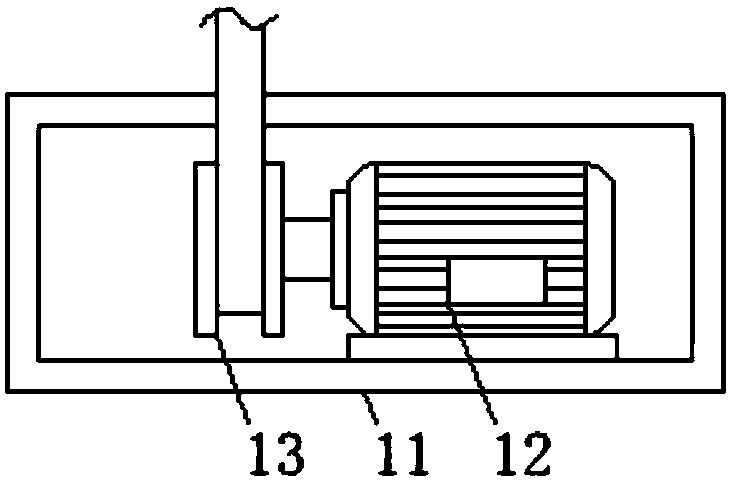

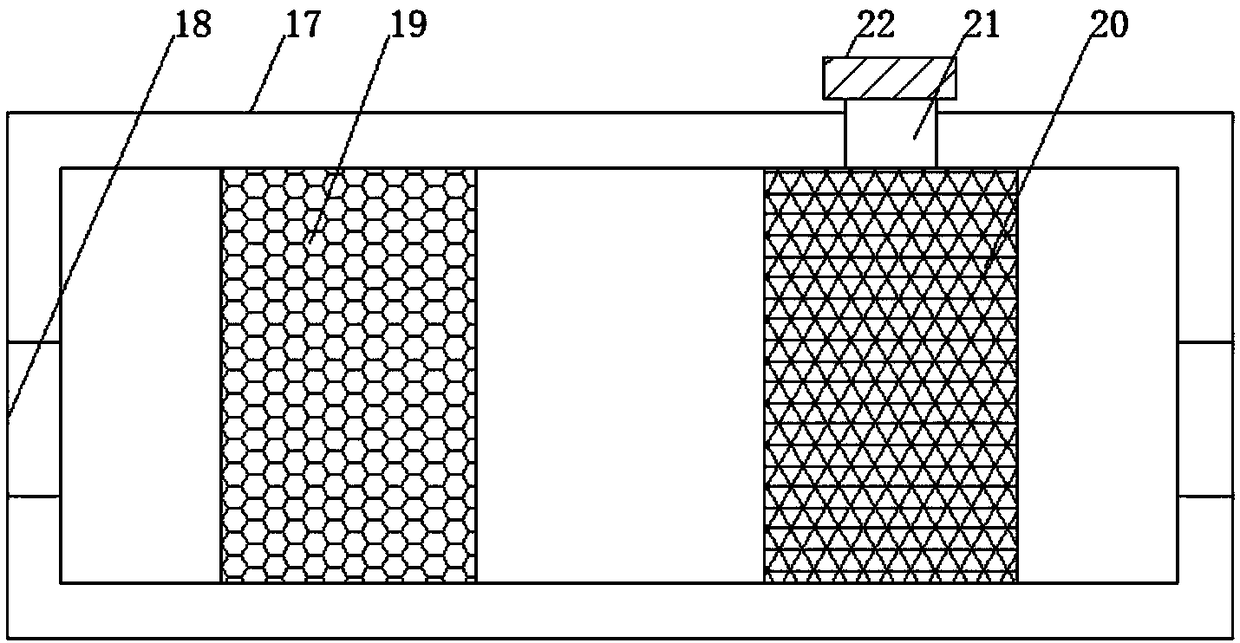

[0021] Such as Figure 1-3 As shown, the present invention provides a technical solution: an in-pipe wire pulling device for building intelligent installation engineering, including a base plate 1, the bottom of the base plate 1 is fixedly connected with a foot 25, and the bottom of the foot 25 is fixedly connected There are anti-slip mats, which can prevent cheap appearance when the whole device is running. The two sides of the top of the bottom plate 1 are respectively fixedly connected with the bottoms of the two support plates 2, and the middle positions of the opposite sides of the two support plates 2 pass through the rotating shaft 3 It is fixedly connected with both sides of the winding roller 4, the right end of the rotating shaft 3 runs through the right side of the support plate 2 and is fixedly connected with the left side of the first driven wheel 5, and the right side of the bottom plate 1 is fixedly connected with a rotating motor 6, and the rotating motor 6 A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com