Dispenser rack convenient to combine with production line

A dispensing machine and production line technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of wasting cost and hindering the combination of dispensing machine and production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

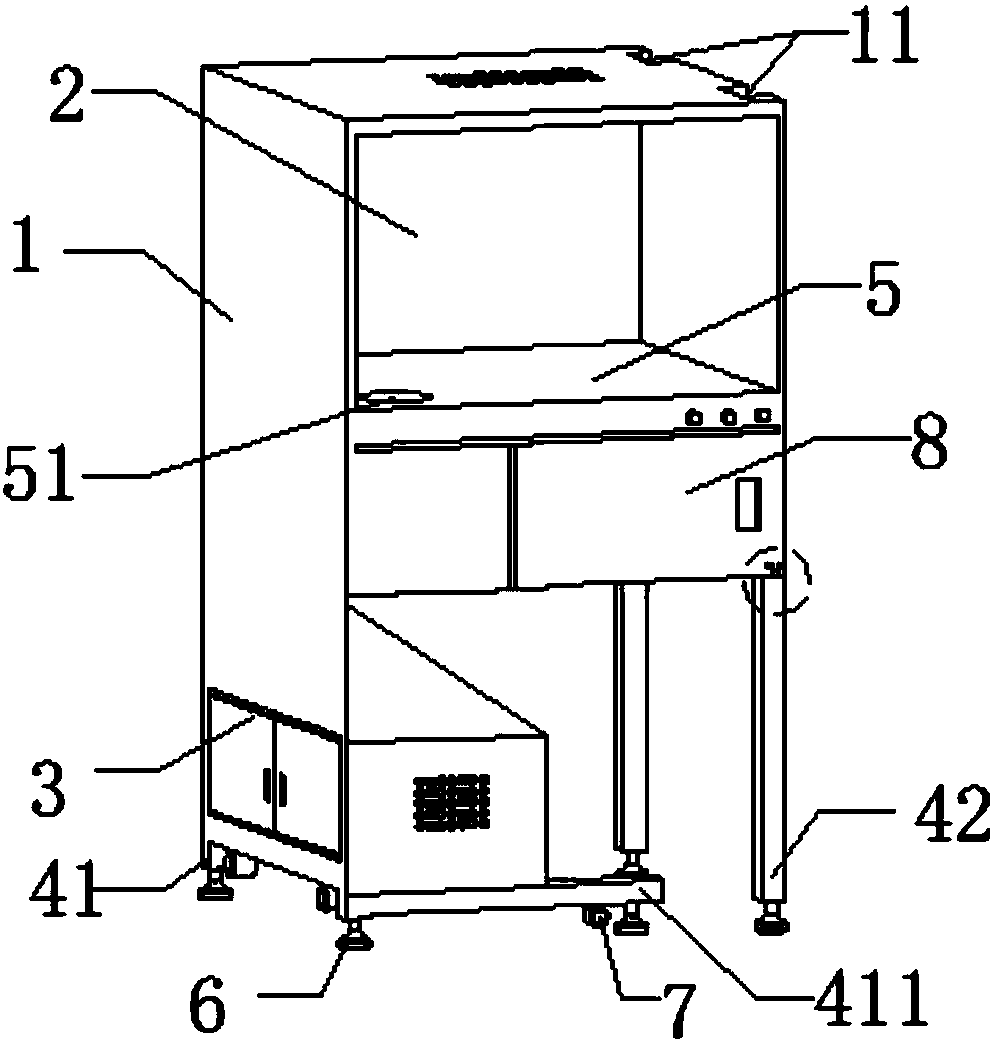

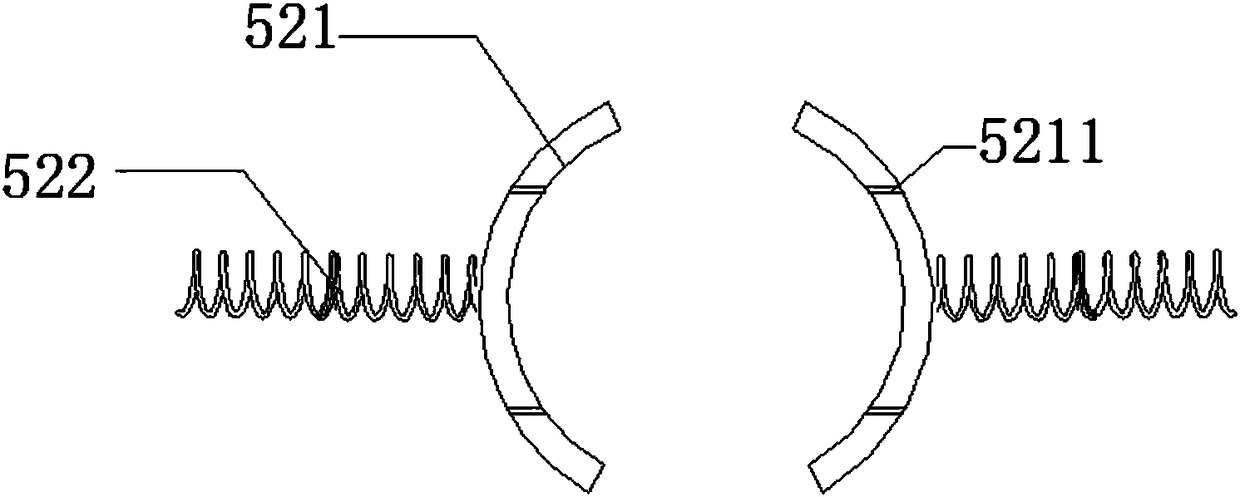

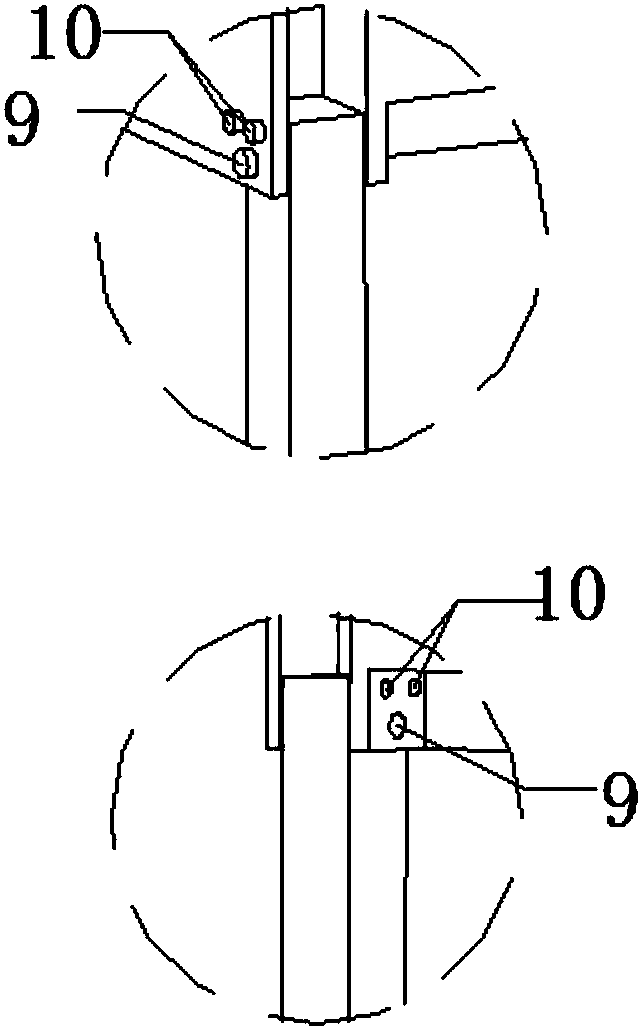

[0023] A dispensing machine frame convenient for production line combination, comprising: a casing 1, a first accommodation chamber 2, a second accommodation chamber 3, a tripod 4, a telescopic support foot 6 is provided at the lower end of the tripod, and the first accommodation chamber 2 is located at the upper end of the casing 1, and the second accommodating chamber 3 is located at the lower end of the casing 1. A first partition plate 5 is provided between the first accommodating chamber 2 and the second accommodating chamber 3, and the first partition plate 5 is close to the second One side of the housing chamber 3 is provided with a threading hole 51 for wiring, and the tripod 4 includes two conjoined tripods 41 on one side of the bottom end of the casing 1 and two off-body tripods 42 on the other side, wherein The vertical direction of the one-piece tripod 41 is fixedly connected with a cross arm 411 and the lower end of the cross arm 411 is provided with a telescopic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com