A production line based on SMD electronic components

A technology for electronic components and production lines, applied to electrical components, resistors, resistors manufactured by photolithography, etc., can solve the problems of reducing the printing quality of printing machines, the impact of printing effects on printing machines, and the lack of cleaning mechanisms, etc., to achieve optimized tin Air filtration process, easy to adjust, optimize the effect of the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

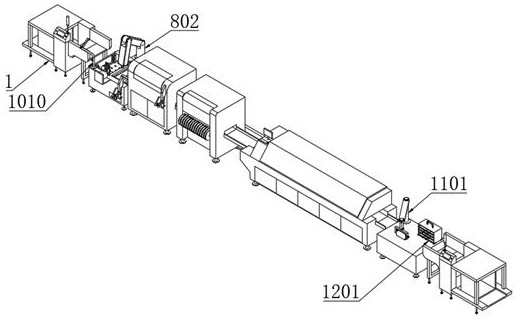

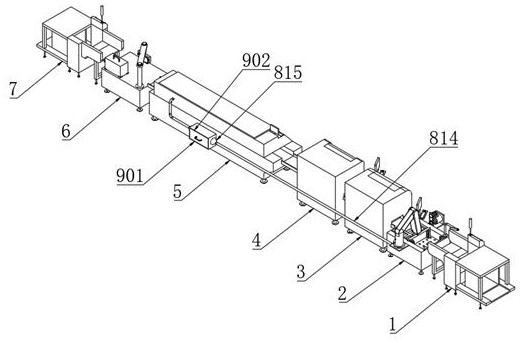

[0038] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a production line based on patch electronic components, including an automatic board loading body 1, one side of the automatic board loading body 1 is connected with a fixed base 2, and one side of the fixed base 2 is connected with a printing Body 3, one side of printing machine body 3 is connected with SMT body 4, one side of SMT body 4 is connected with soldering reflow furnace body 5, one side of soldering reflow furnace body 5 is placed with fixed seat 6, one side of fixed seat 6 is connected There is an automatic lower plate body 7, and a cleaning mechanism 8 is arranged on the top of the fixed base 2;

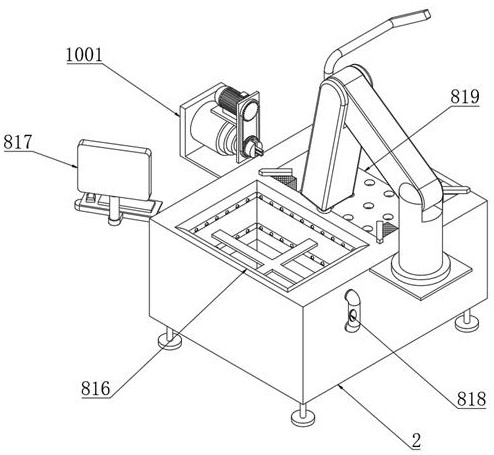

[0039] The cleaning mechanism 8 comprises a fixed plate 801, a mechanical arm 802, a vacuum chuck 803, a rotating motor 804, a rotating disc 805, a stirring blade 806, a positioning groove 807, a positioning frame 808, an active carbon filter screen 809, a support frame 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com