Sulphur analyzer with automatic sample feeder

A technology for sulfur determination instrument and sample delivery, which is applied in the field of sulfur determination instrument, can solve the problems of lowering work efficiency, inability to spread coal samples, and small bottom area, so as to improve accuracy and stability, improve work efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

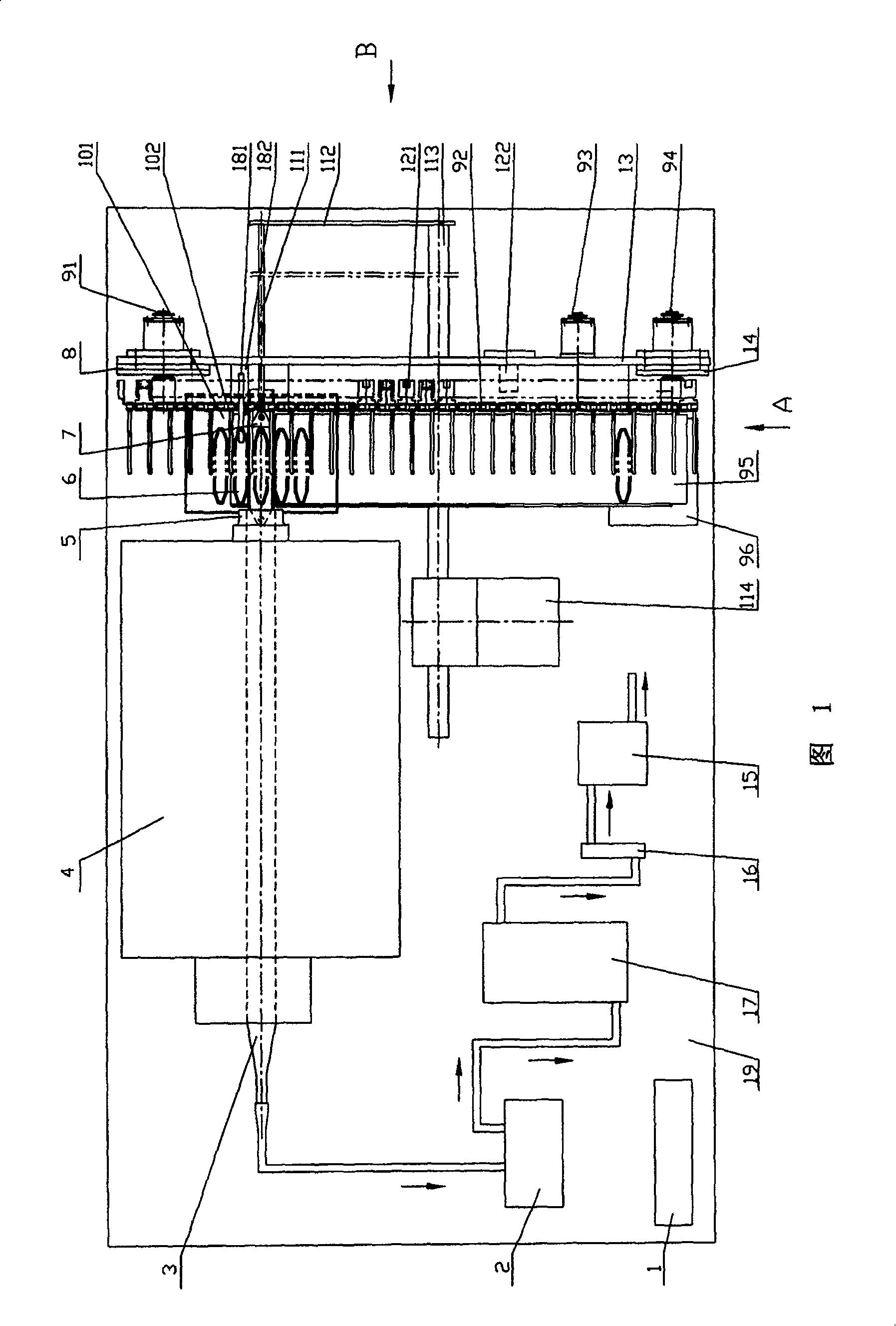

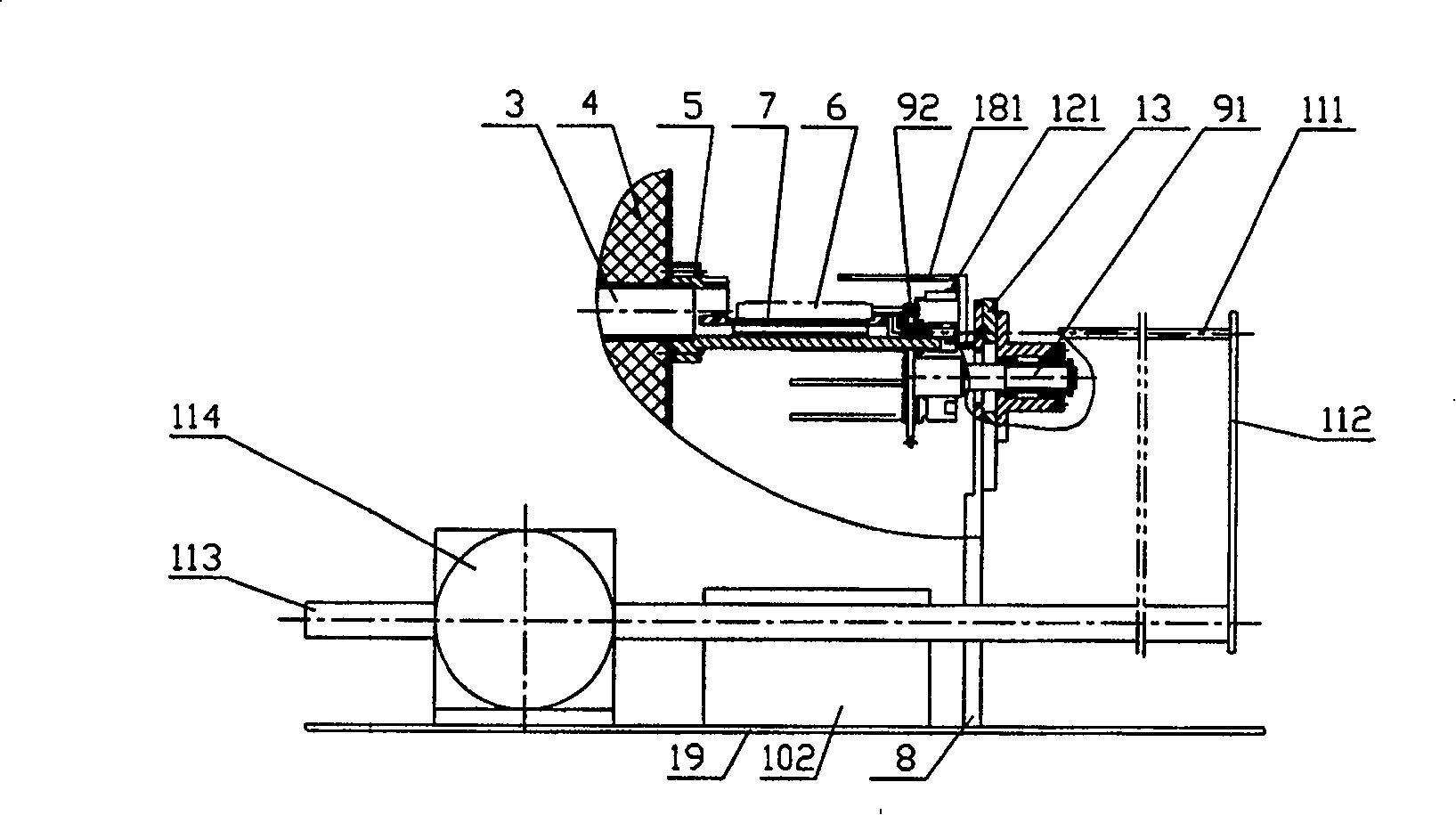

[0035] Embodiment 1: Fig. 1, figure 2 and image 3As shown, the sulfur determination instrument with an automatic sample delivery device of the present invention includes a furnace body 4 fixed on a bottom plate 19, a control mechanism 1, and a sulfur amount sensing device 2, a drying device 17, and a flow sensing device connected in sequence through pipelines. device 16 and circulation pump 15, a combustion tube 3 is installed in the furnace body 4, and the sulfur amount sensing device 2 is connected to the tail end of the combustion tube 3 through a pipeline. The sample delivery nozzle 5 is connected with an automatic sample delivery device. The automatic sample feeding device includes a chain-like conveying mechanism, a sample feeding mechanism and a positioning device. Among them, the control mechanism 1 is used to control the movement, positioning and data collection of the entire instrument; the sulfur sensor device 2 is used to analyze the sulfur content in the airflo...

Embodiment 2

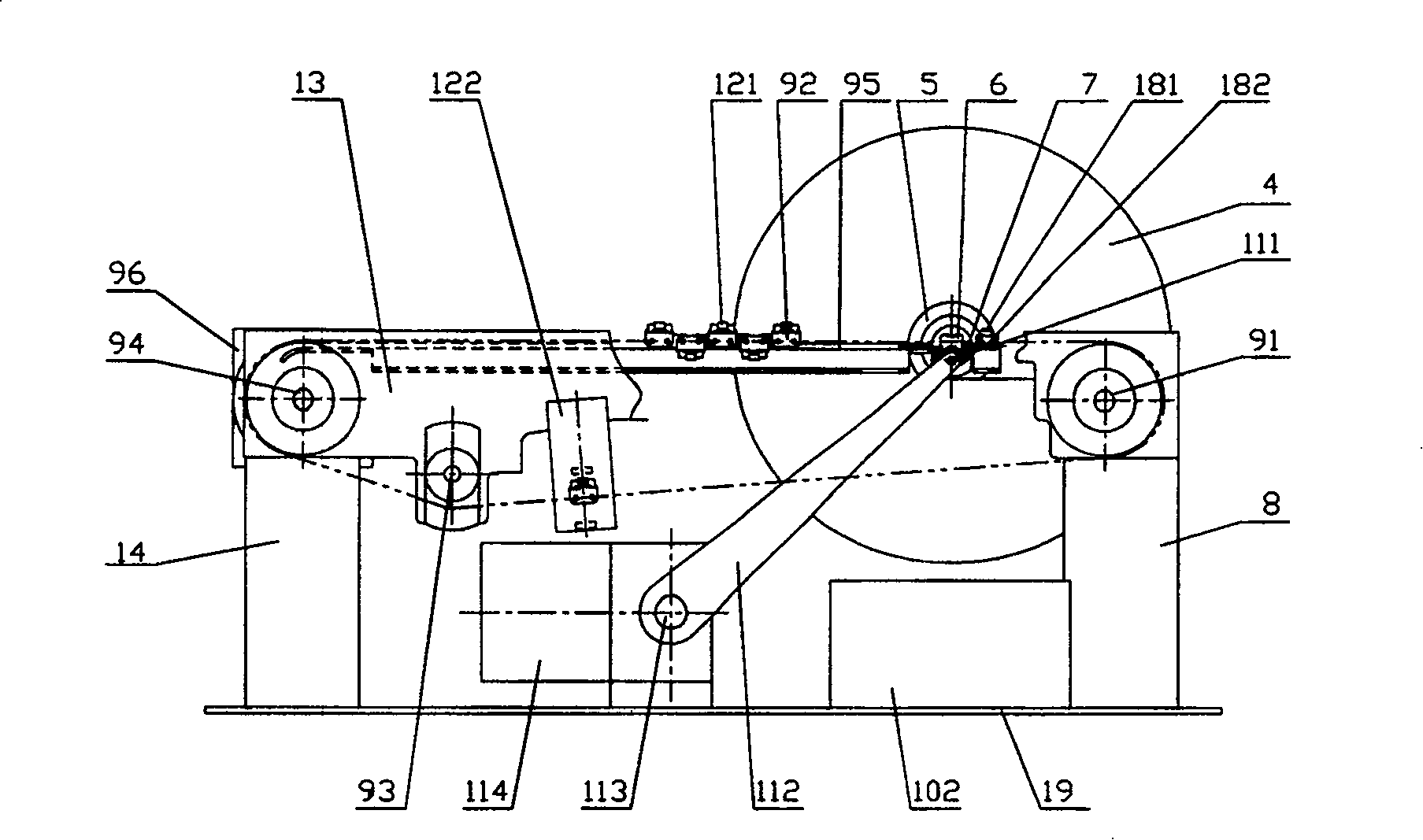

[0037] Embodiment 2: as shown in Figure 4 and Figure 5 As shown, the sulfur determination instrument with an automatic sample delivery device of the present invention includes a furnace body 4 fixed on the bottom plate, a control mechanism 1, and a sulfur amount sensing device 2 connected in sequence through pipelines, a drying device 17, and a flow sensor. 16 and a circulating pump 15, a combustion tube 3 is installed in the furnace body 4, and the sulfur amount sensing device 2 is connected to the tail end of the combustion tube 3 through a pipeline. The sample delivery nozzle 5 is connected with an automatic sample delivery device. The automatic sample delivery device includes a disc type transmission mechanism, a sample delivery mechanism and a positioning device. Among them, the control mechanism 1 is used to control the movement, positioning and data collection of the entire instrument; the sulfur sensor device 2 is used to analyze the sulfur content in the airflow ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com