Cable leading-down facility for established double-circuit strain tower

A technology for tension towers and cables, applied in the spatial arrangement/configuration of cables, etc., can solve problems such as not too close spacing, waste of resources, poor overall aesthetics, etc., achieve a wide range of applicable voltage levels, reduce construction costs, and avoid demolition and reconstruction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

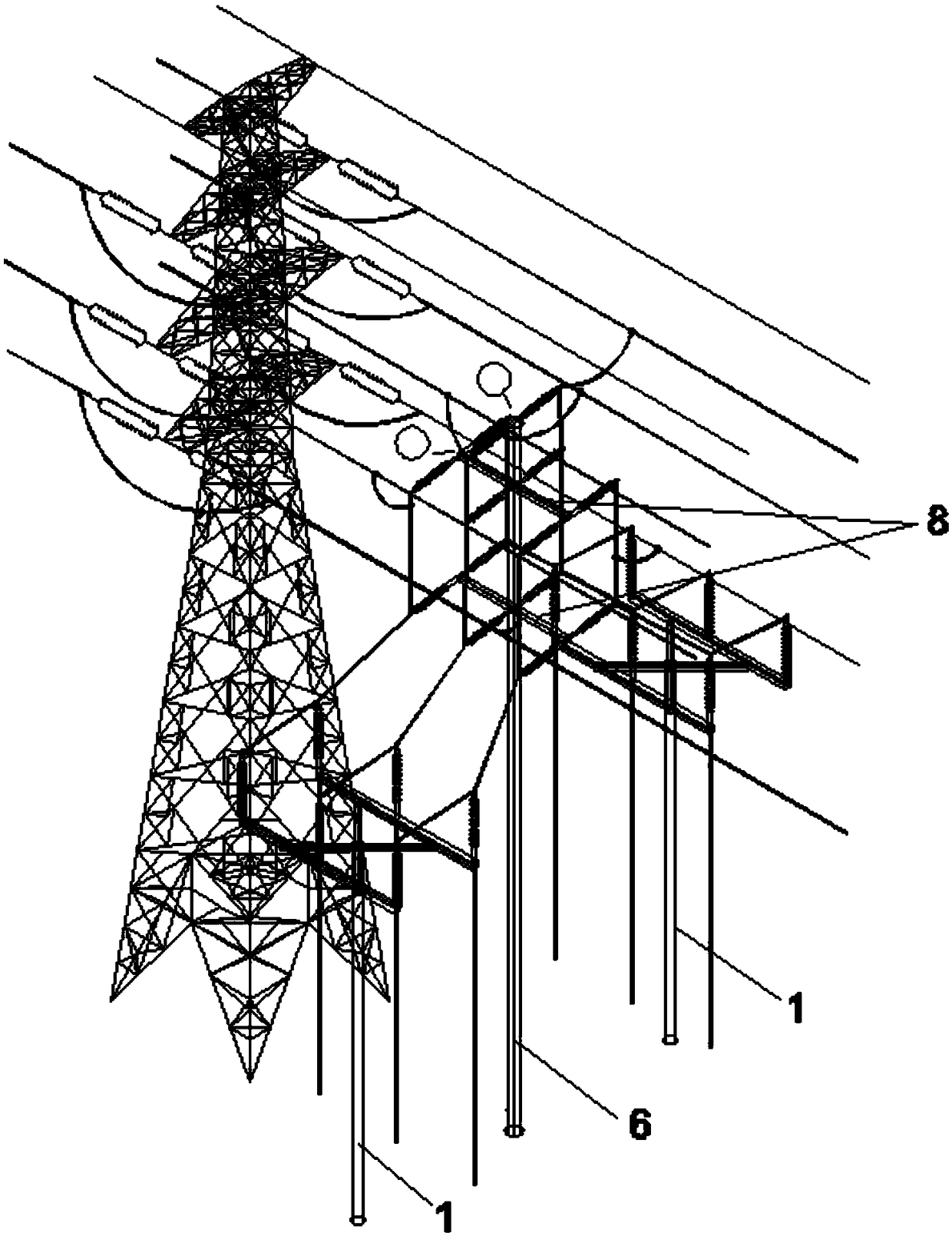

[0014] Such as Figure 1-4 As shown in Fig. 1, a cable down-conduction facility for an established double-circuit tension tower consists of two parts: an independent cap and a down-conductor tower.

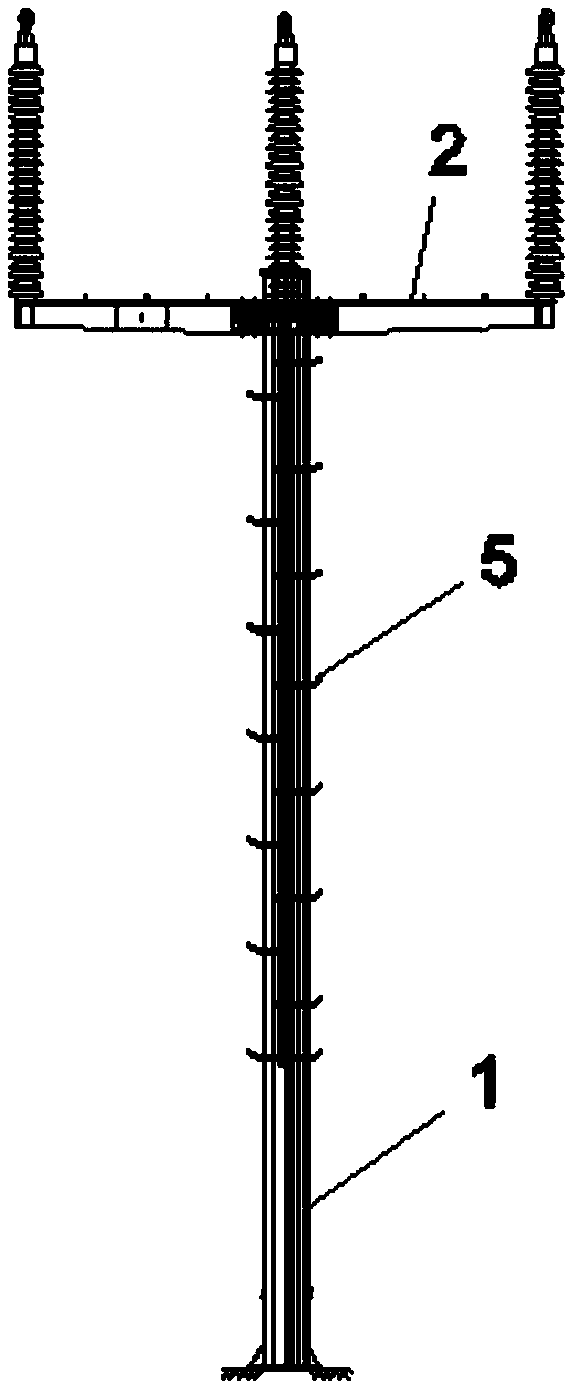

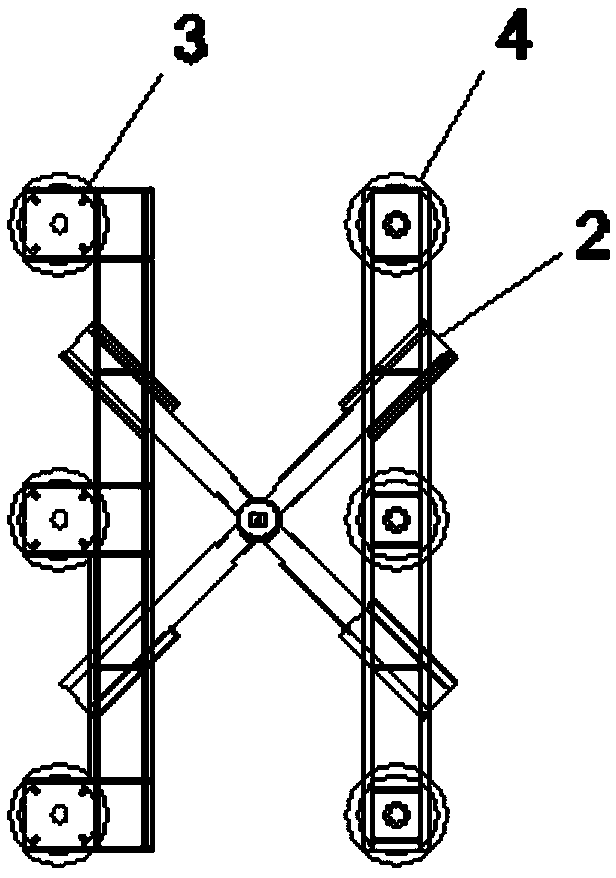

[0015] The independent platform includes a support rod 1 , a support platform 2 , a seat type cable terminal 3 , and a seat type lightning arrester 4 .

[0016] The support platform 2 is set above the cross arm at the top of the support rod 2, and is composed of an "X"-shaped cross arm and a "one"-shaped cross arm. The angle between the "X"-shaped cross arm and the transmission line is 45 degrees, and the upper part is used for supporting "One"-shaped cross arm, seat type cable terminal 3, seat type lightning arrester 4, the center is located on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap