Motor and mounting and adjusting device for pedestal thereof

A technology for installing and adjusting bolts, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of affecting the service life of adjusting bolts, large wear and tear of adjusting bolts, etc., to maintain stability, reduce vibration force, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

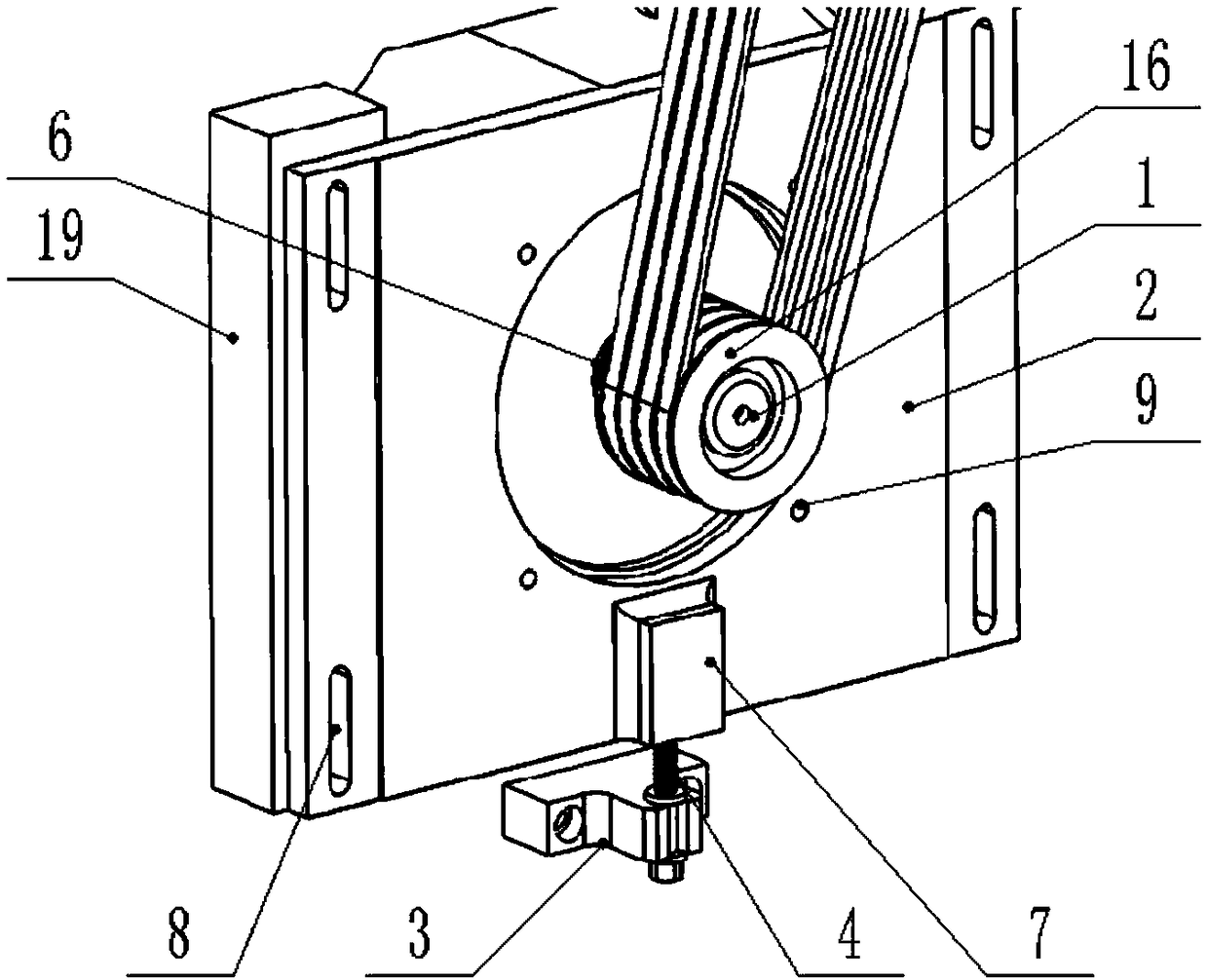

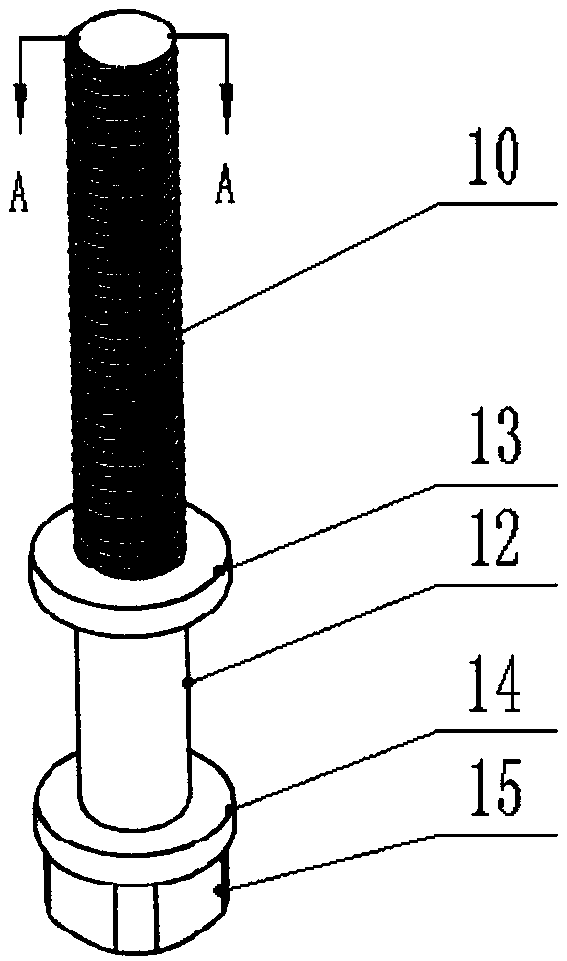

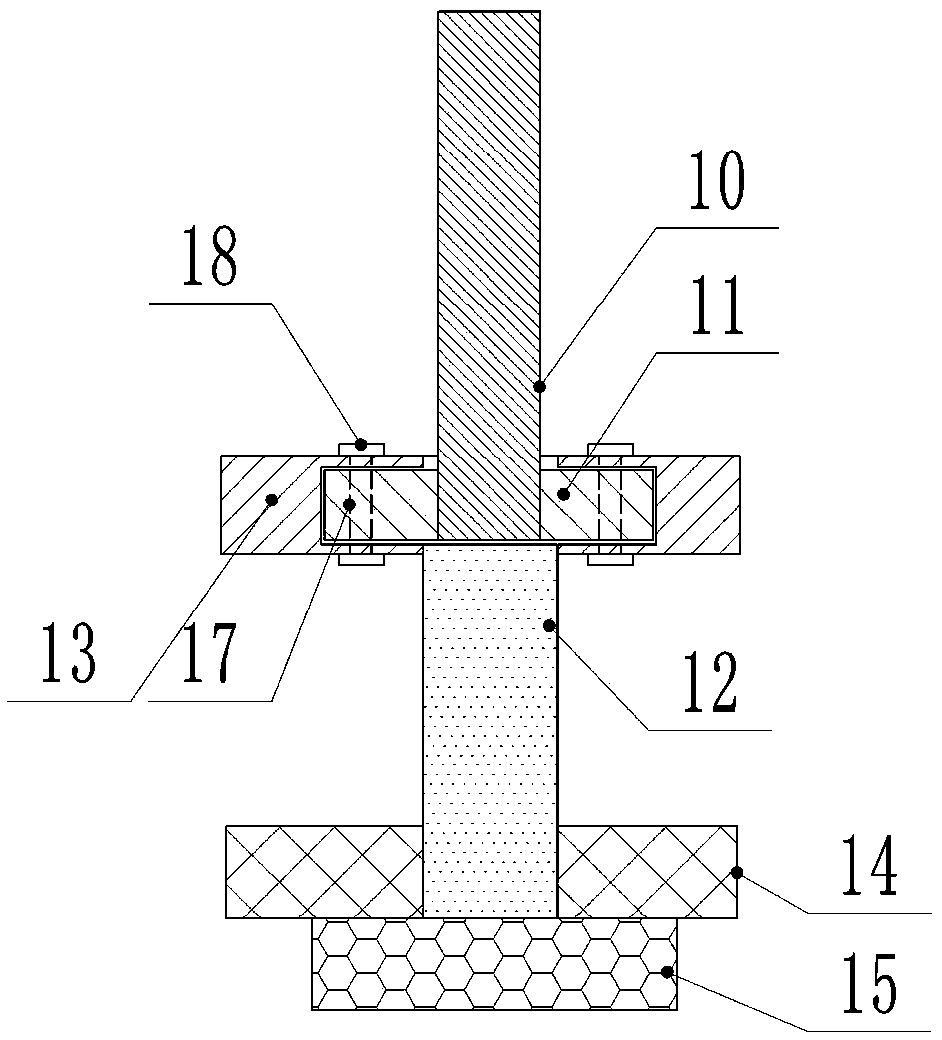

[0022] The reference signs in the drawings of the specification include: motor spindle 1, plate body 2, adjustment seat 3, adjustment bolt 4, clip groove 5, perforation 6, bump 7, strip hole 8, positioning hole 9, rod body 10, protrusion Ring 11, tail body 12, first flange 13, second flange 14, screw 15, tensioning wheel 16, inserting rod 17, limit block 18, machine tool 19.

[0023] Example figure 1 Shown: a motor and its base installation adjustment device, including adjustment bolt 4, plate body 2, adjustment seat 3 and motor body.

[0024] The structure of adjusting bolt 4 is as follows: figure 2 As shown, including a rod body 10 and a tail body 12, the rod body 10 is provided with threads, the tail body 12 is provided with a first flange 13 and a second flange 14, the first flange 13, the tail body 12 and the second flange 14 are distributed in an I shape. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com