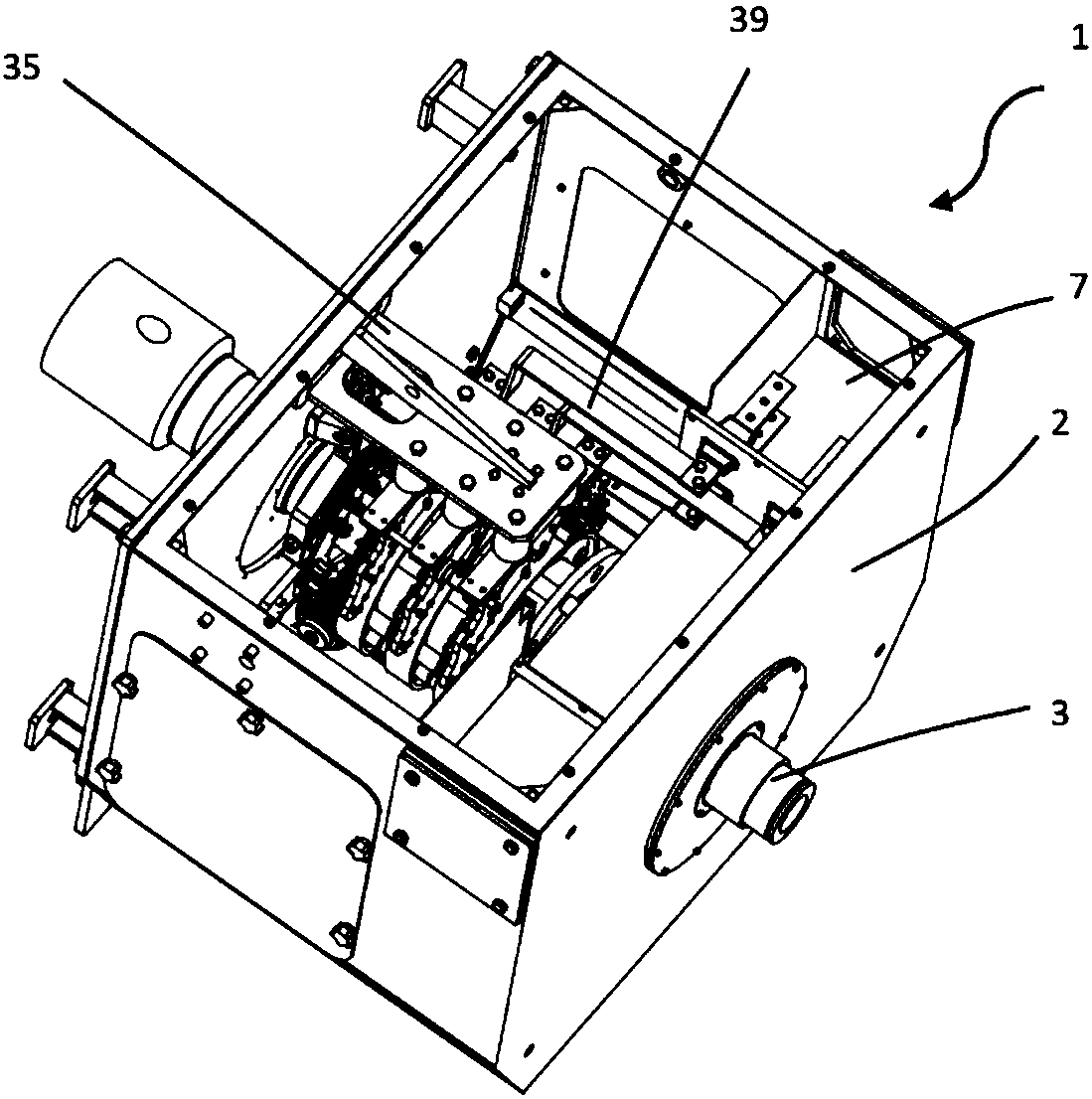

Slipring unit for a wound rotor motor

A winding, motor technology, applied in asynchronous induction motors, electrical components, rotating current collectors, etc., can solve the problems of troublesome setting and maintenance, and high motor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

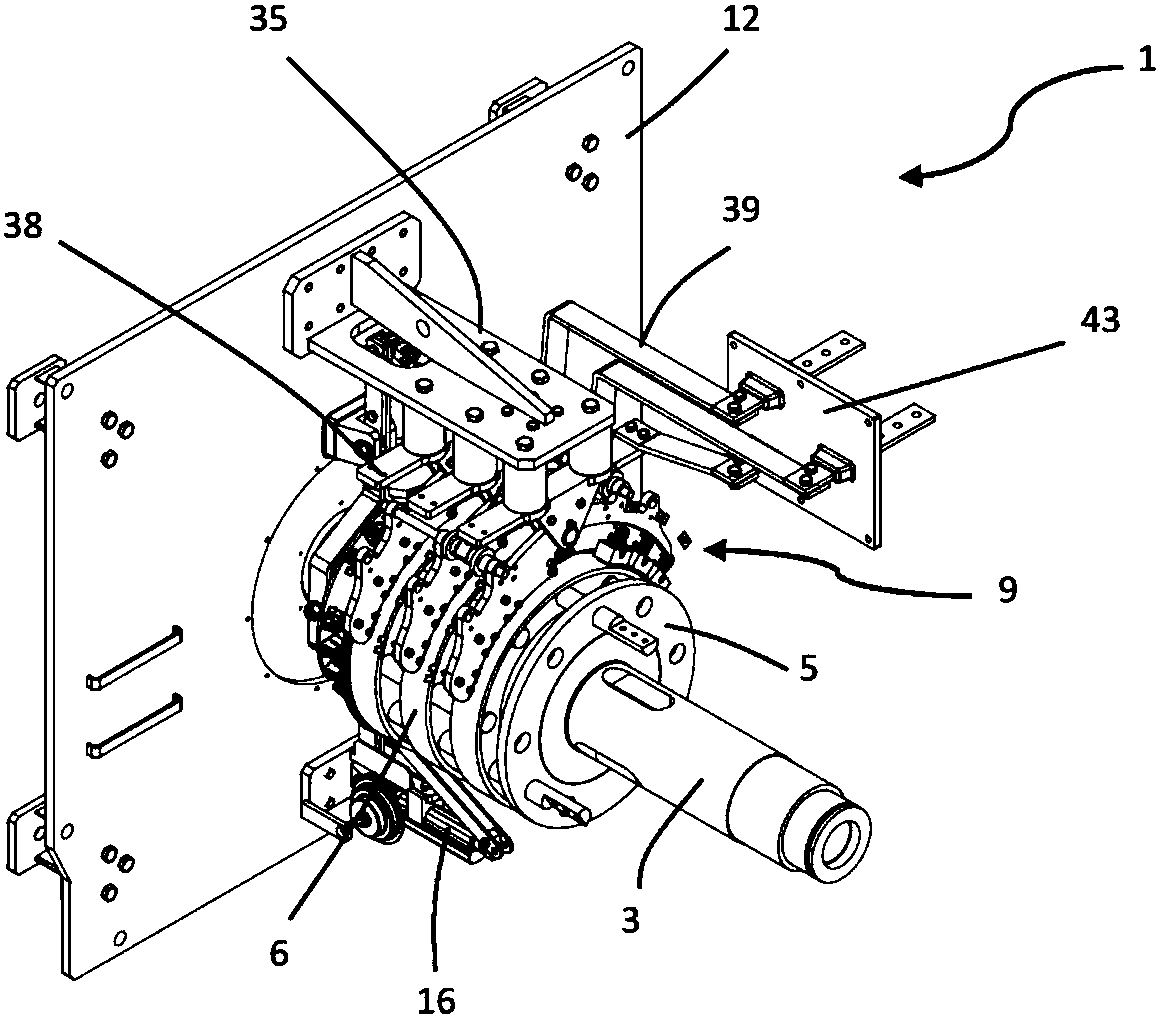

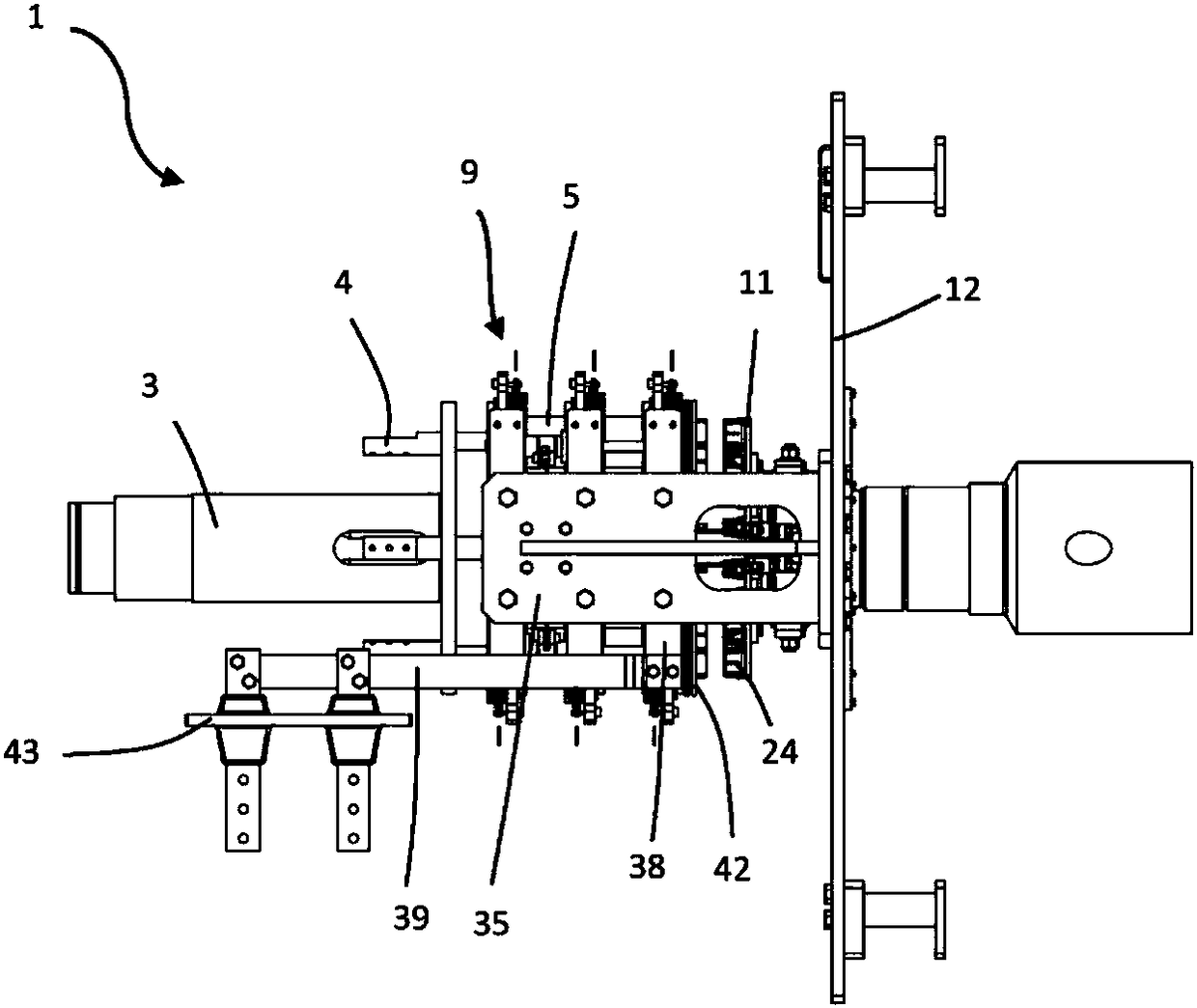

[0053] According to one embodiment, each brush assembly 9 includes a protruding portion 38, which can be, for example, a fixed plate 30 extending transverse to the axial direction of the shaft 3, preferably extending perpendicular to the axial direction of the shaft 3. Part. Still more preferably, the protruding portion 38 extends on both sides of the brush assembly 9. The protruding portion 38 is electrically connected to the brush 10 and electrically insulated from the support frame 35. For example, the protruding portion 38 may be positioned between the insulating spacer 36 and the fixing plate 30, wherein the fixing plate 30, the plate pivot 31, the half plate 29, and the brush holder 32 are made of conductive materials.

[0054] According to a possible embodiment, the actuator 16 is in the upper position (see Figure 7 ), the support frame 35 can also form an actuator plate 46.

[0055] Advantageously, the unit 1 includes an auxiliary conductive rod 39 for electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com