Linear vibration motor

A technology of linear vibration and vibration unit, which is applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of small driving force and long vibration response time, and achieve the effect of improving driving force and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

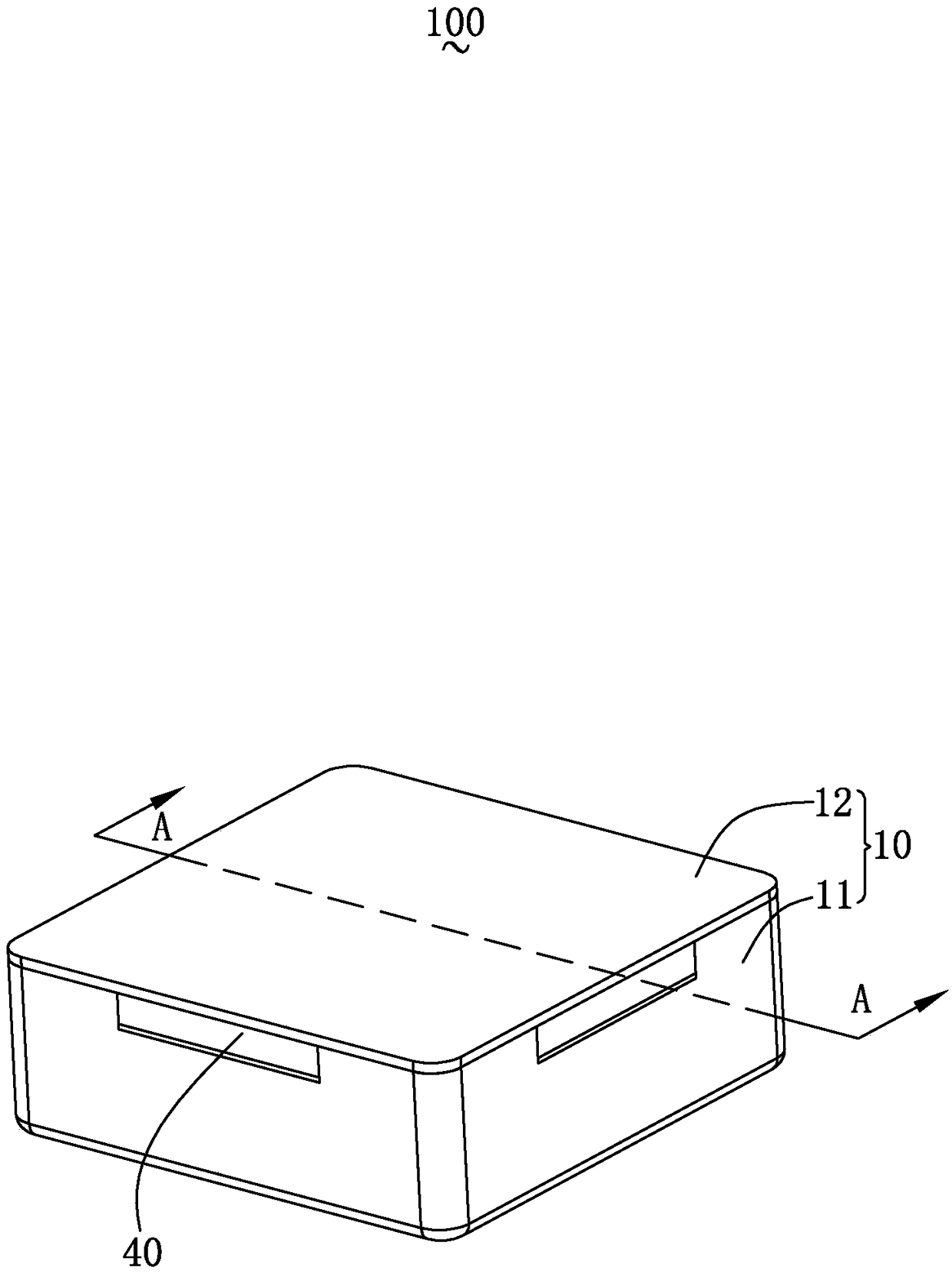

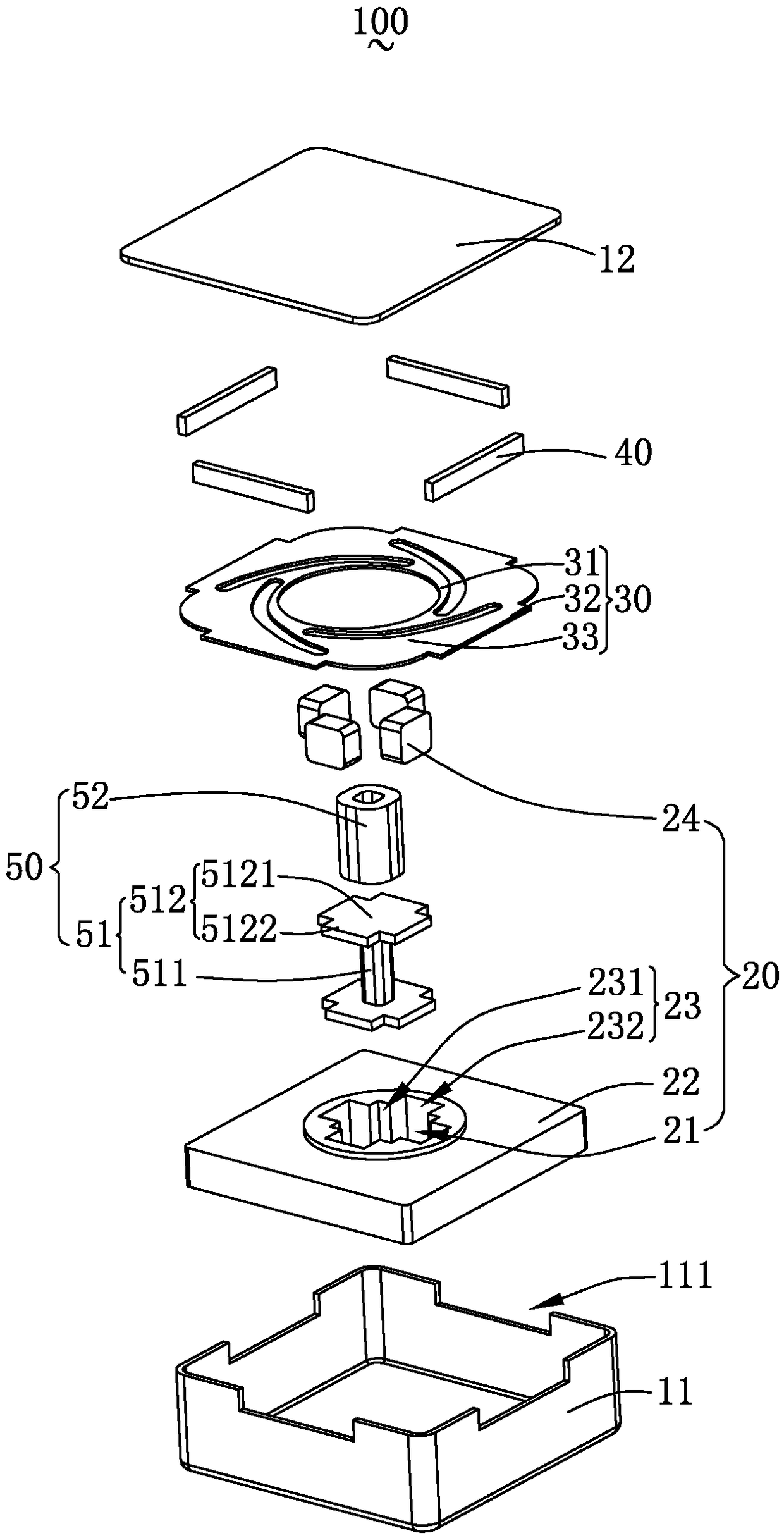

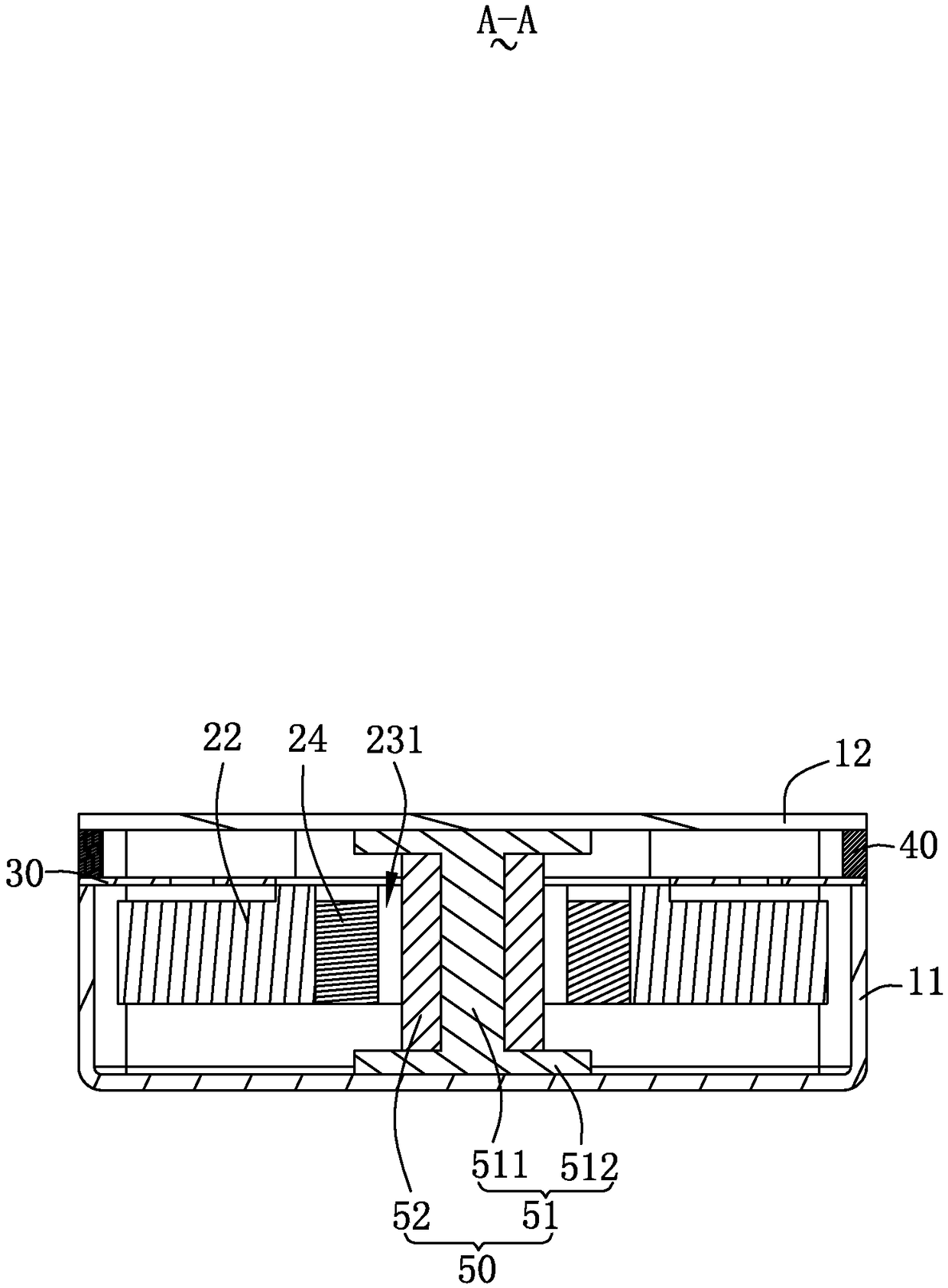

[0027] Please refer to Figure 1 to Figure 3 . The present invention provides a linear vibration motor 100, which includes a housing 10 with a housing space, a vibration unit 20 accommodated in the housing space, and an elastic component for suspending the vibration unit 20 in the housing space 30. The baffle 40 disposed on the casing 10 and the driving unit 50 for driving the vibrating unit 20 to vibrate.

[0028] The casing 10 includes a first casing 11 having a side wall and a second casing 12 covering the first casing 11 and forming the receiving space.

[0029] The vibration unit 20 includes a mass 22 having a through hole 21 , a permanent magnet support 23 installed in the through hole 21 , and a permanent magnet 24 embedded in the permanent magnet support 23 .

[0030] Specifically, the mass block 22 is made of a non-magnetic material.

[0031] The permanent magnet bracket 23 includes a rectangular through hole 231 located at the center of the permanent magnet bracke...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, the difference lies in:

[0055] Please refer to Figure 5 to Figure 7 The vibration unit 120 in the linear vibration motor 200 provided in this embodiment also includes a first magnetically conductive sheet 125 and a second magnetically conductive sheet 126 positioned on the upper surface and the lower surface of the permanent magnet 124 (here the upper surface and the lower surface of the permanent magnet 124 The surfaces are two ends close to the abutting portions 1512 of the two iron cores respectively). In this embodiment, the magnetic circuit structure adopts a permanent magnet array structure so that the driving force received by the mass block 122 is better, and the response speed of the linear vibration motor 200 is faster.

[0056] Compared with the related art, the linear vibration motor provided by the present invention is set by arranging the iron core so that the coil is wound around the iron core bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com