Piezoelectric motor with variable rotate speed and torque, and use method thereof

A piezoelectric motor and torque technology, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. To meet the output requirements and other issues, to achieve the effect of high torque-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

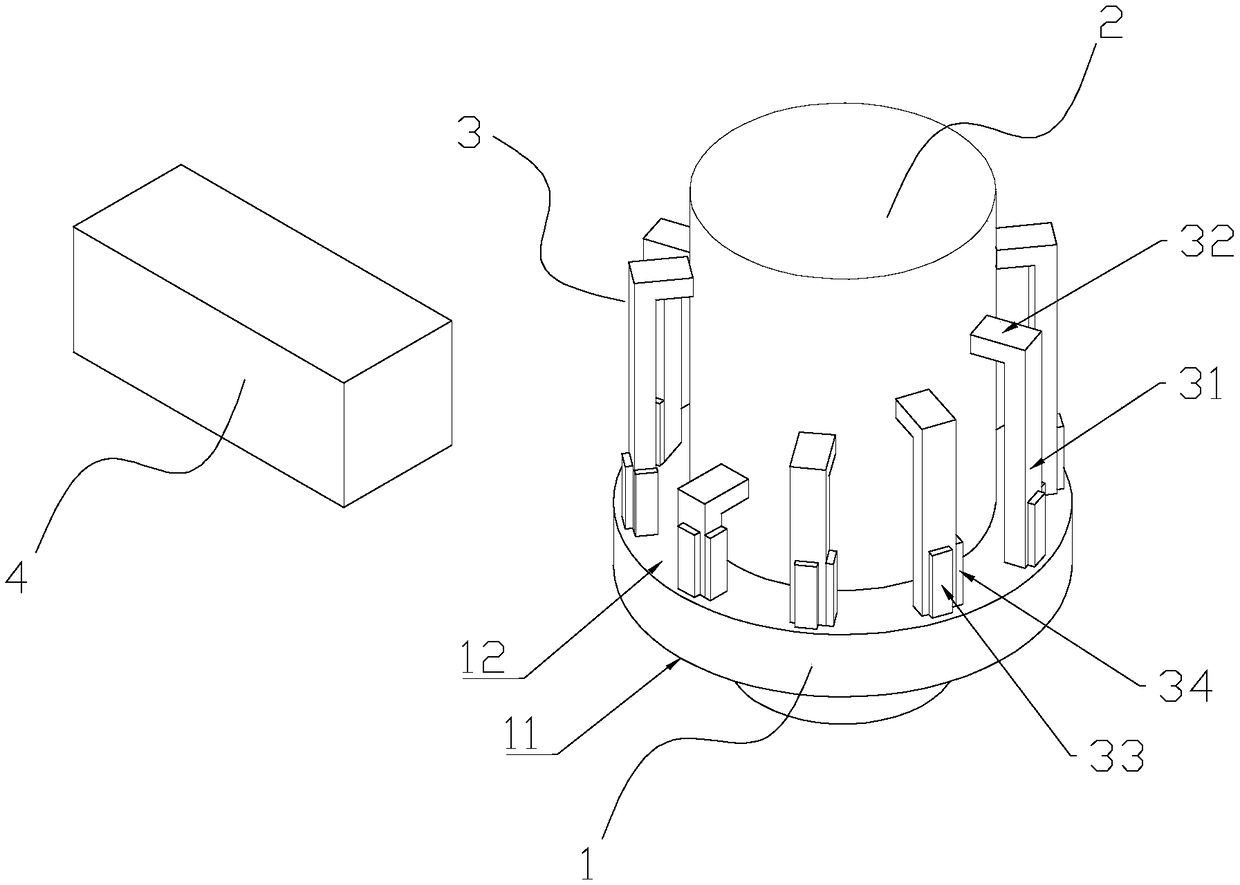

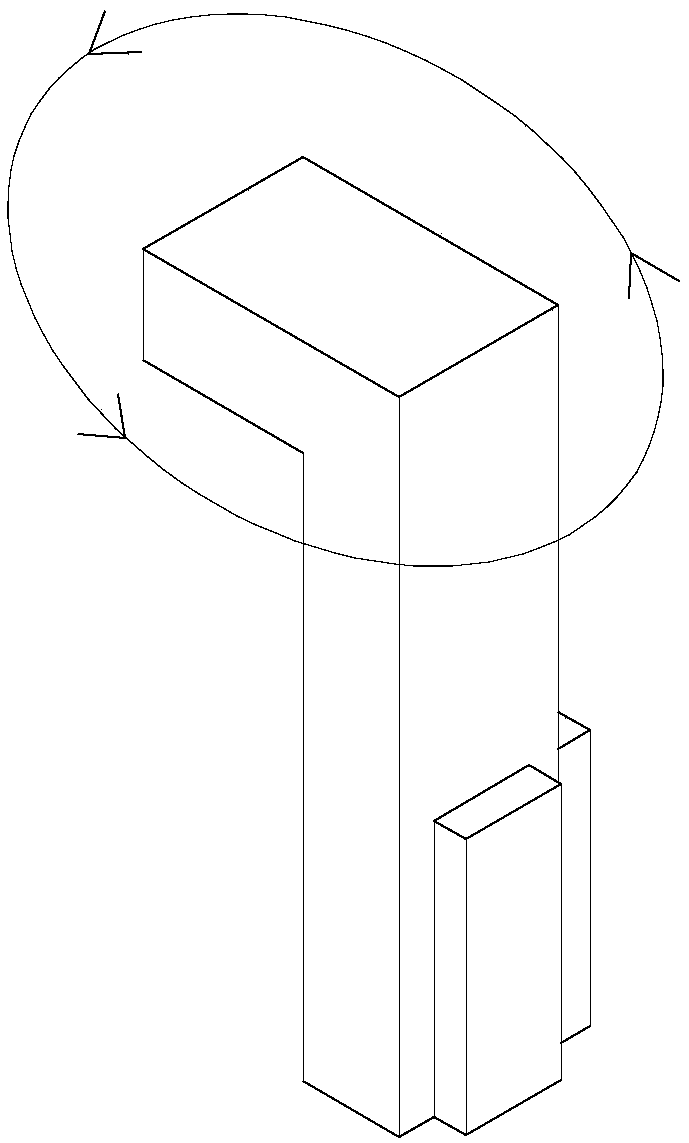

[0024] Such as figure 1 As shown, a piezoelectric motor with variable torque and rotating speed includes an annular stator base 1, the stator base 1 includes a first end face 11 and a second end face 12, and a rotatable rotor 2 is provided in the middle of the stator base 1, The second end surface 11 of the stator seat 1 is provided with a driving part 3, and the driving part 3 is driven by the driver 4. The driving part 3 includes multiple groups of driving legs with different lengths. The number of driving legs in this embodiment is preferably five groups. The number of driving feet in the group is not less than two and the lengths are equal. The driving feet of the same group are evenly arranged along the circumference of the second end face 12. The number of driving feet in this embodiment is preferably two; because the length of the driving feet is different, the resonant frequency Also different, the driving frequency of the driver 4 driving different groups of driving f...

Embodiment 2

[0028] A method for using a piezoelectric motor with variable torque and rotational speed, the method comprising:

[0029] 1) Select the driver that matches the rotor speed

[0030] Introduce the calculation formula of the rotor speed v

[0031] v=f*X qn *60 / 2*3*π*r

[0032] Among them, f is the driving frequency of the driver; X qn is the swing amplitude of each driving foot in the direction perpendicular to the rotor radius, q is the number of groups, n is the number of driving feet of any driving group; rotor radius r;

[0033] According to the above measured parameters and the required rotor speed, the drive frequency f required for the output speed is calculated. Since the frequencies of driving different groups of drive legs are different, the drive legs that meet the drive frequency f can be determined;

[0034] 2) Select the number of driving feet that output the rotor torque

[0035] Introduce the calculation formula of rotor torque

[0036] M=(λ q1 +λ q2 +......

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com