Alternate-current servo motor control system

A technology of AC servo motor and control system, which is applied in the direction of AC motor control, control system, electrical components, etc. It can solve the problems of speed control technical performance not promoting power supply, slowing down and improving, and increasing maintenance workload, so as to achieve easy maintenance , easy heat dissipation, low moment of inertia effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

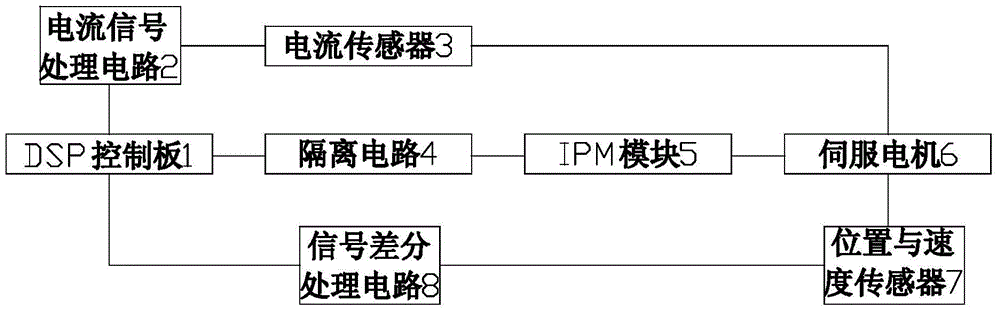

[0010] figure 1 It is a structural schematic diagram of the control system of the AC servo motor of the present invention. The control system of the AC servo motor of the present invention is characterized in that: DSP control board 1, current signal processing circuit 2, current sensor 3, isolation circuit 4, IPM module 5. Servo motor 6, position and speed sensor 7, signal differential and processing circuit 8;

[0011] The DSP control board 1 is connected to the current signal processing circuit 2, the DSP control board 1 is connected to the isolation circuit 4, the DSP control board 1 is connected to the signal differential and processing circuit 8, and the current The signal processing circuit 2 is connected to the current sensor 3, the current sensor 3 is connected to the IPM module 5, the IPM module 5 is connected to the isolation circuit 4, and the IPM module 5 is connected to the servo motor 6, The servo motor 6 is connected to the position and speed sensor 7 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com