Multi-motor parallel drive type electric joint and mechanical arm thereof

A driven, multi-motor technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problem of low torque-to-weight ratio of electric joints, and achieve the effect of reducing volume and weight and high torque-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

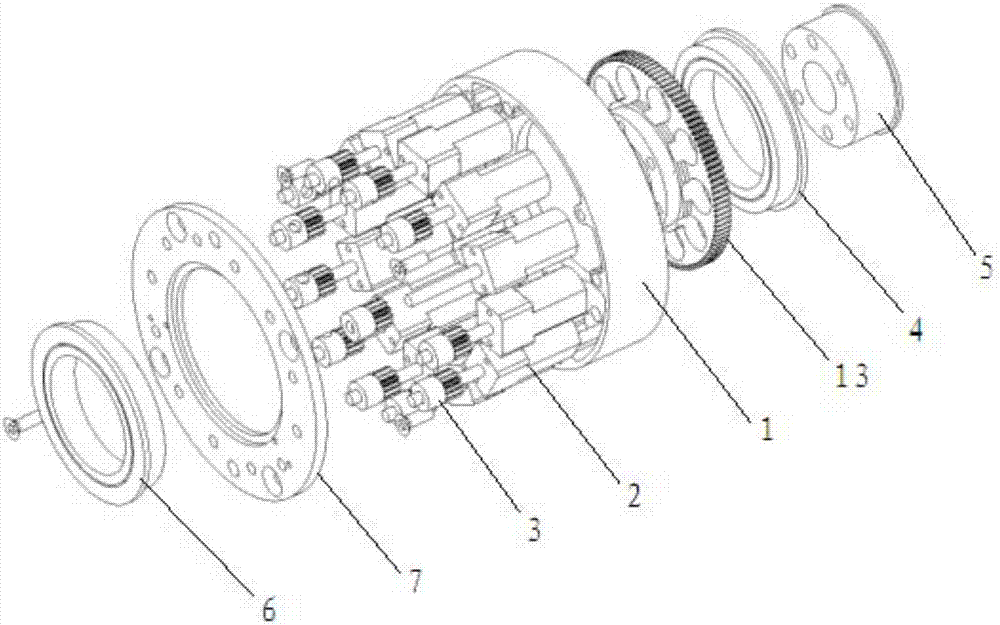

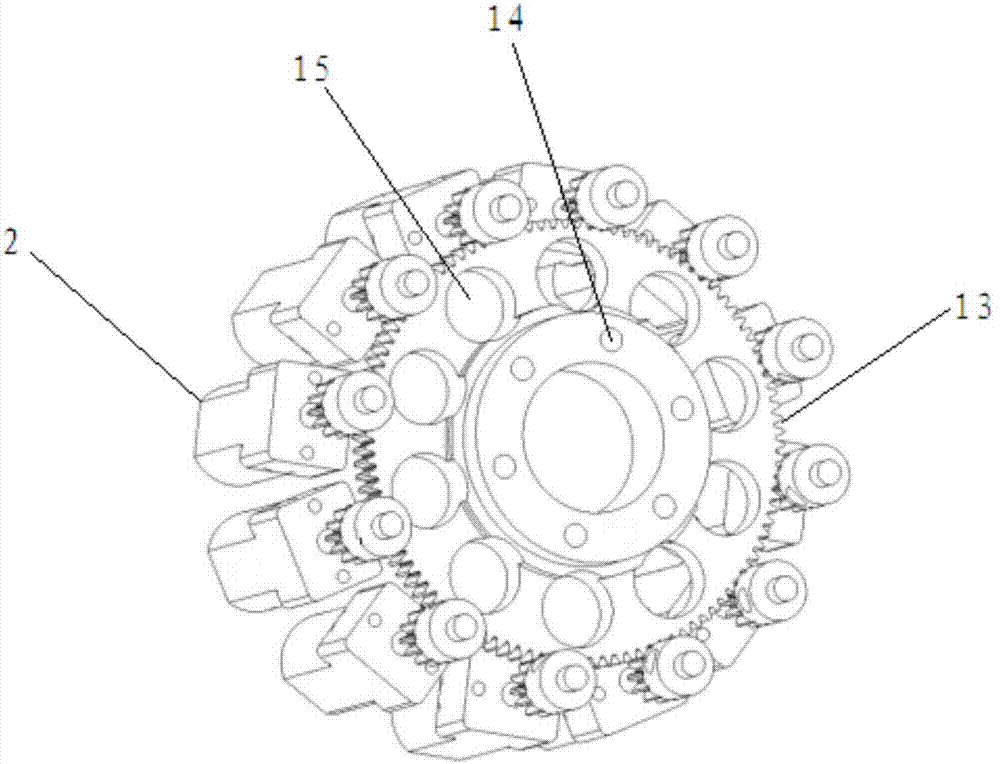

[0036] Such as figure 1 As shown, one specific embodiment of a multi-motor parallel-driven electric joint includes a motor fixing plate 1, a motor 2, a driving gear 3, a support bearing 4, a support bearing fixing block 5, an output bearing 6, and an output bearing fixing Plate 7 and output gear 13.

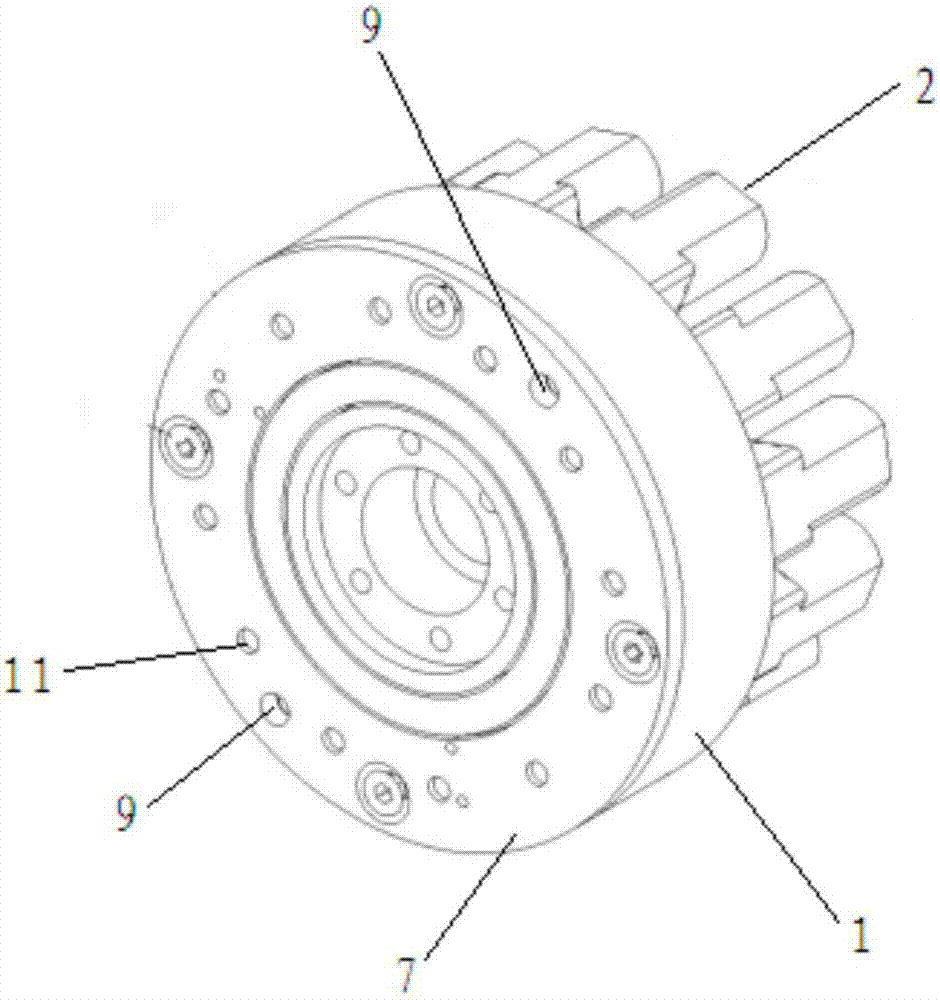

[0037] Such as Figure 1-8 As shown, the motor is mounted on the motor fixing plate. Specifically, the motor fixing plate 1 includes a base 101 , a bearing mounting hole 102 , a motor shaft through hole 103 , a motor fixing hole 104 , a connecting hole 105 and a mounting hole 106 . The base body 101 is disc-shaped with sidewalls. The bearing installation hole 102 is opened at the center of the bottom surface of the base body 101 , and the support bearing 4 is installed in the bearing installation hole 102 . More specifically, the outer ring of the support bearing 4 is clamped in the bearing installation hole 102 , and the inner ring is clamped with the support bearing fixing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com