Ergonomic integrated vehicle vibration-damping chassis and sub-rack device

An ergonomic and box-inserting technology, applied in the direction of chassis/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, vehicle parts, etc., can solve identification, installation and disassembly, complicated operation, vehicle road conditions Harsh, time-consuming and labor-intensive problems, to achieve the effect of simple and quick disassembly and assembly, easy identification and operation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

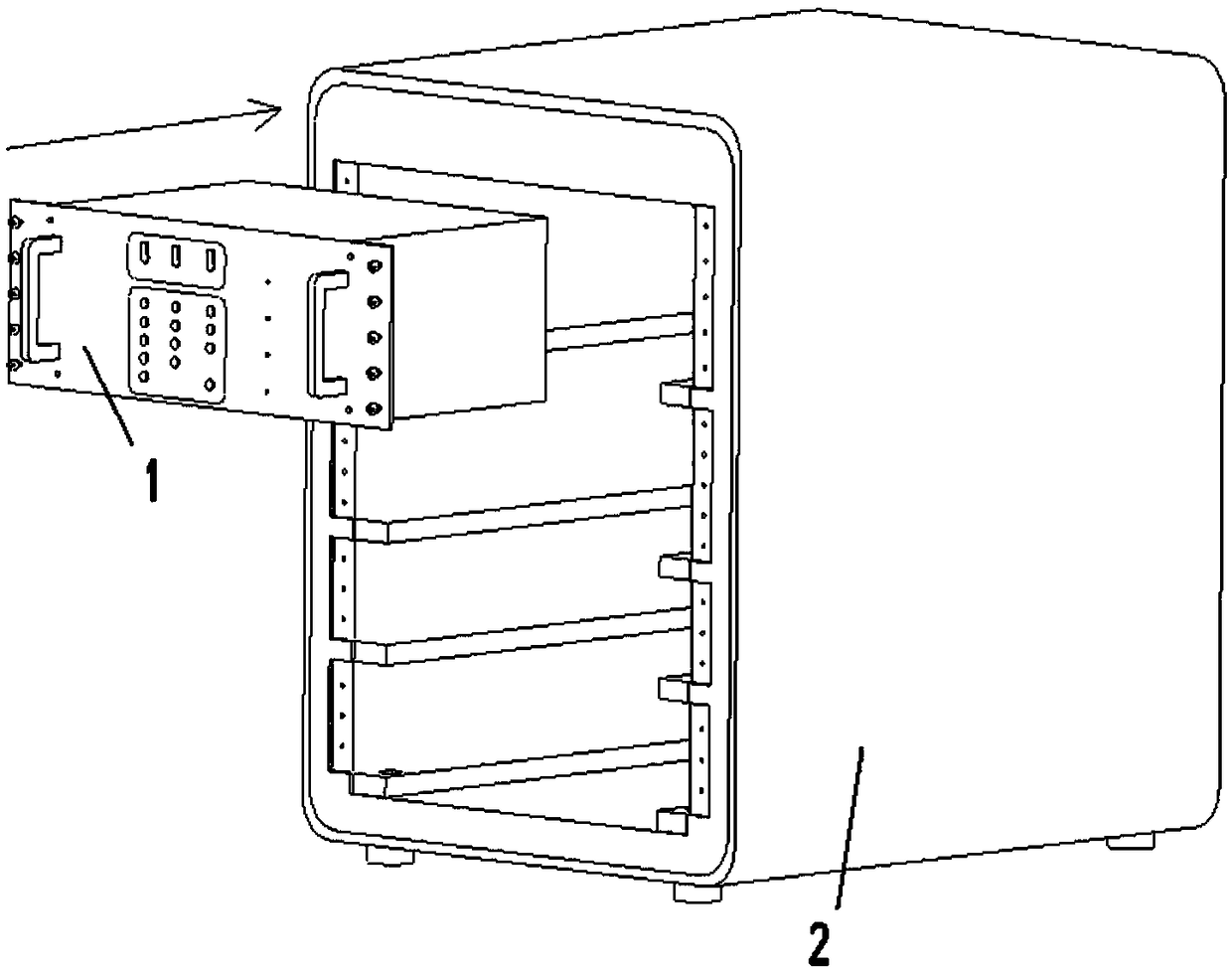

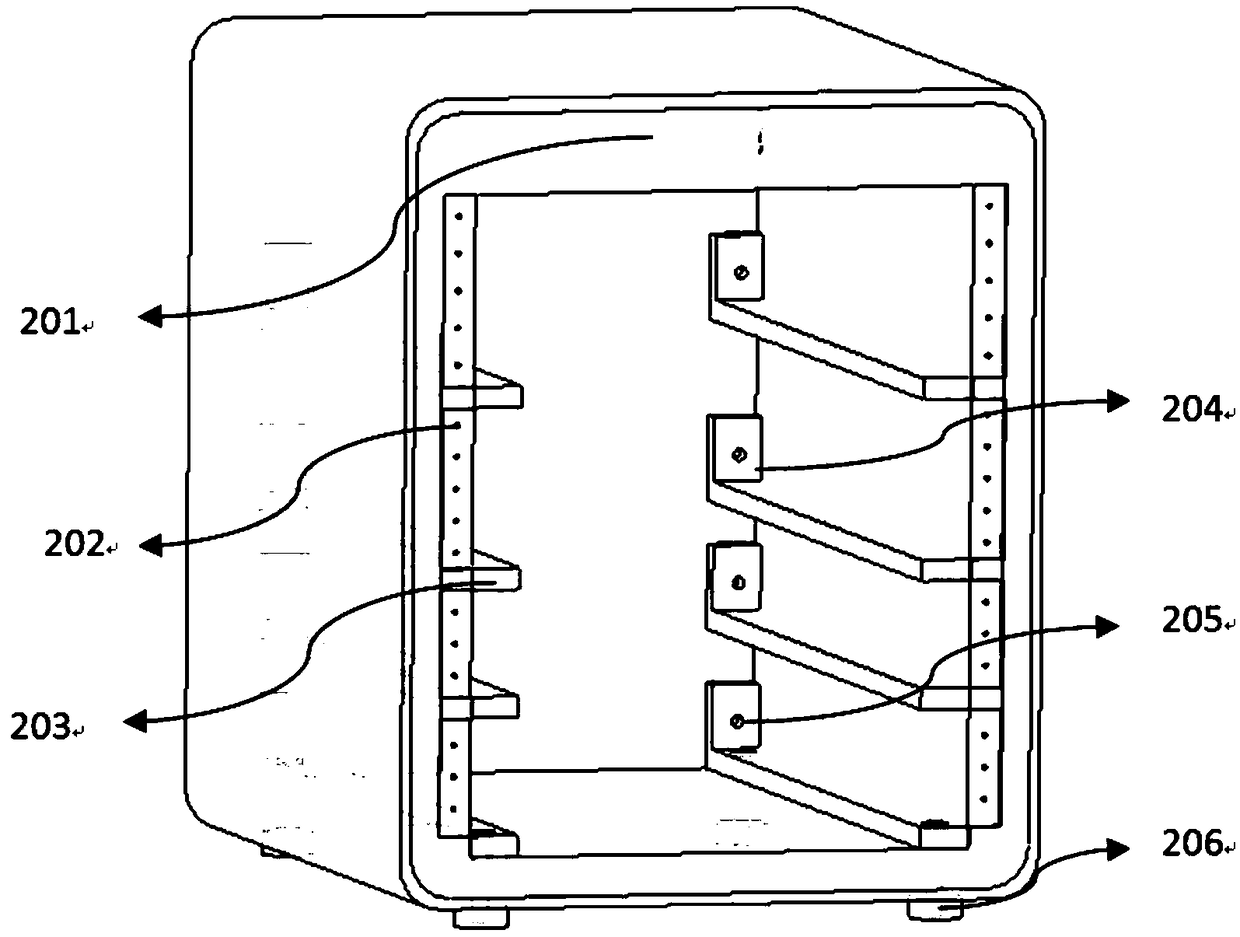

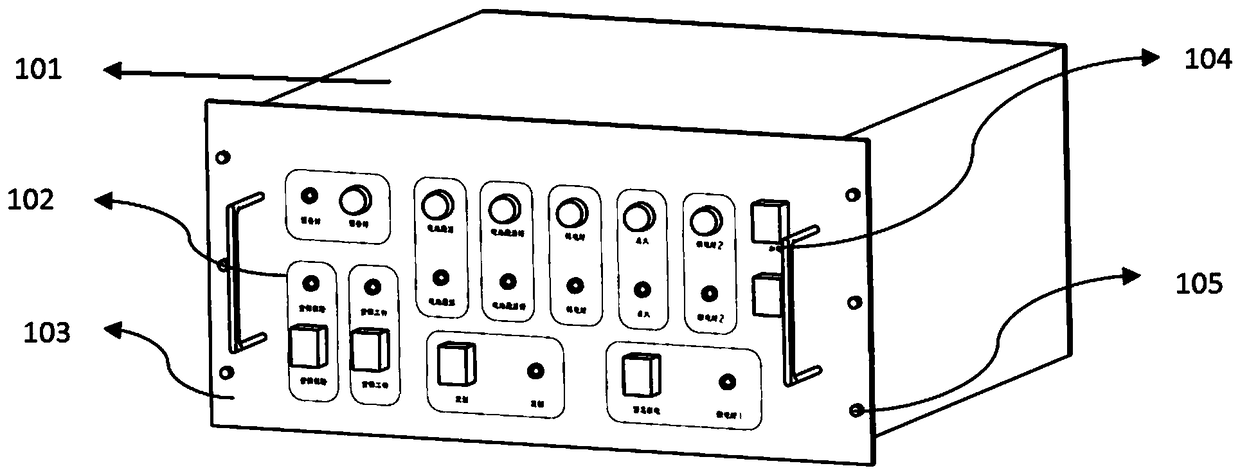

[0025] Based on the idea of miniaturization, the present invention designs a plurality of cabinets that make full use of the space in the cabin and have vibration-reducing performance within the limited space of the vehicle-mounted cabin; the design shape and fixed installation form are unified, and the plug-in boxes installed in the cabinets in a simple and fast manner form equipment.

[0026] The vehicle-mounted cabin often needs to be transferred, and the road conditions are relatively bad, which is prone to vibration and shock. Therefore, the single machine installed inside the cabin needs to have good vibration damping and shock resistance performance to maintain the normal operation of the single machine. Since the single machine is fixedly installed in the chassis , so the chassis is designed as a vibration-absorbing chassis. For equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com