Common mode choke coil

A common mode choke coil and coil technology, applied in the direction of transformer/inductor coil/winding/connection, inductor, inductor with magnetic core, etc., can solve the problems of expanding the core 101, unable to reduce the invalid area, etc. Achieve the effect of increasing the cross-sectional area and increasing the L value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

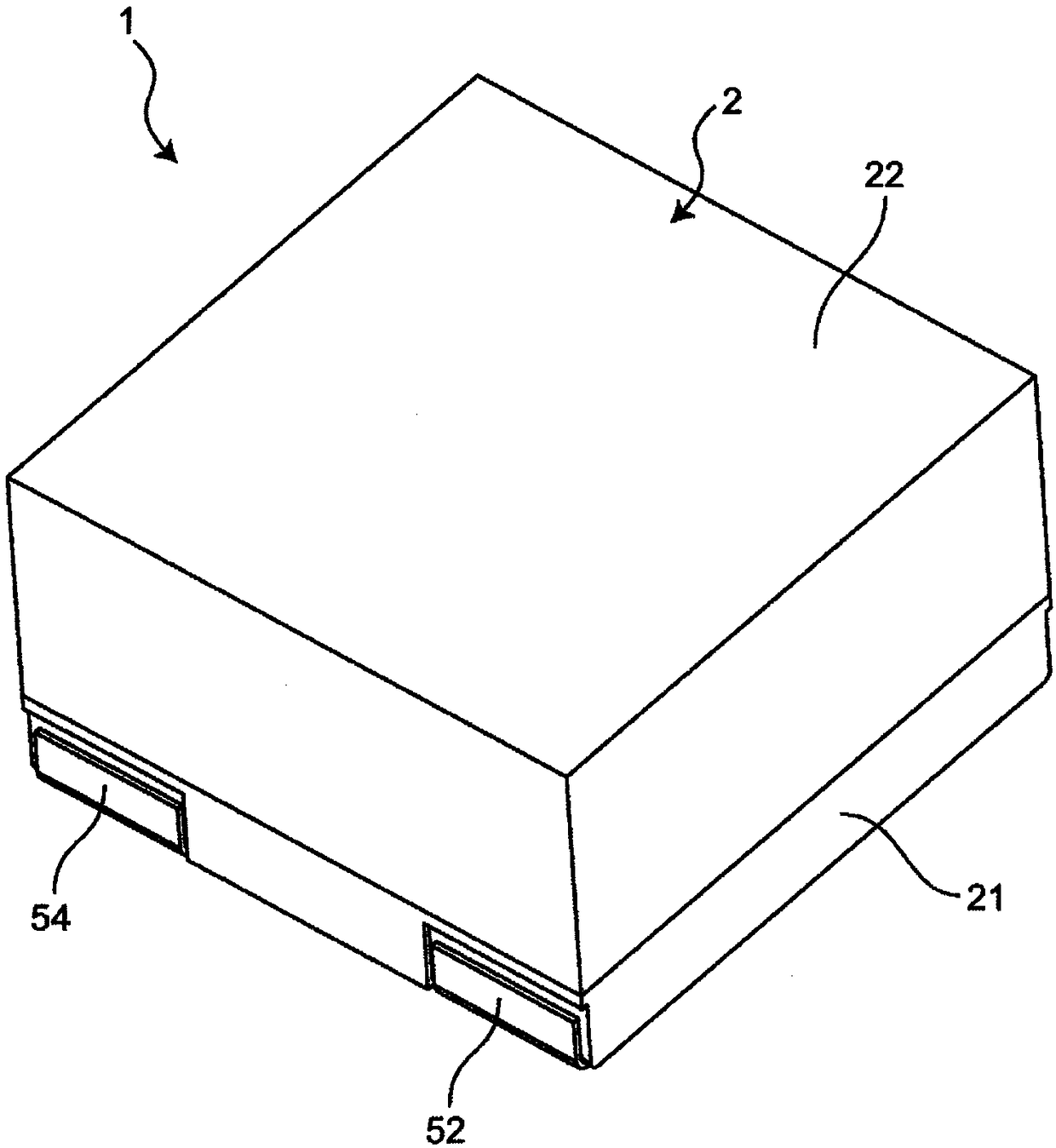

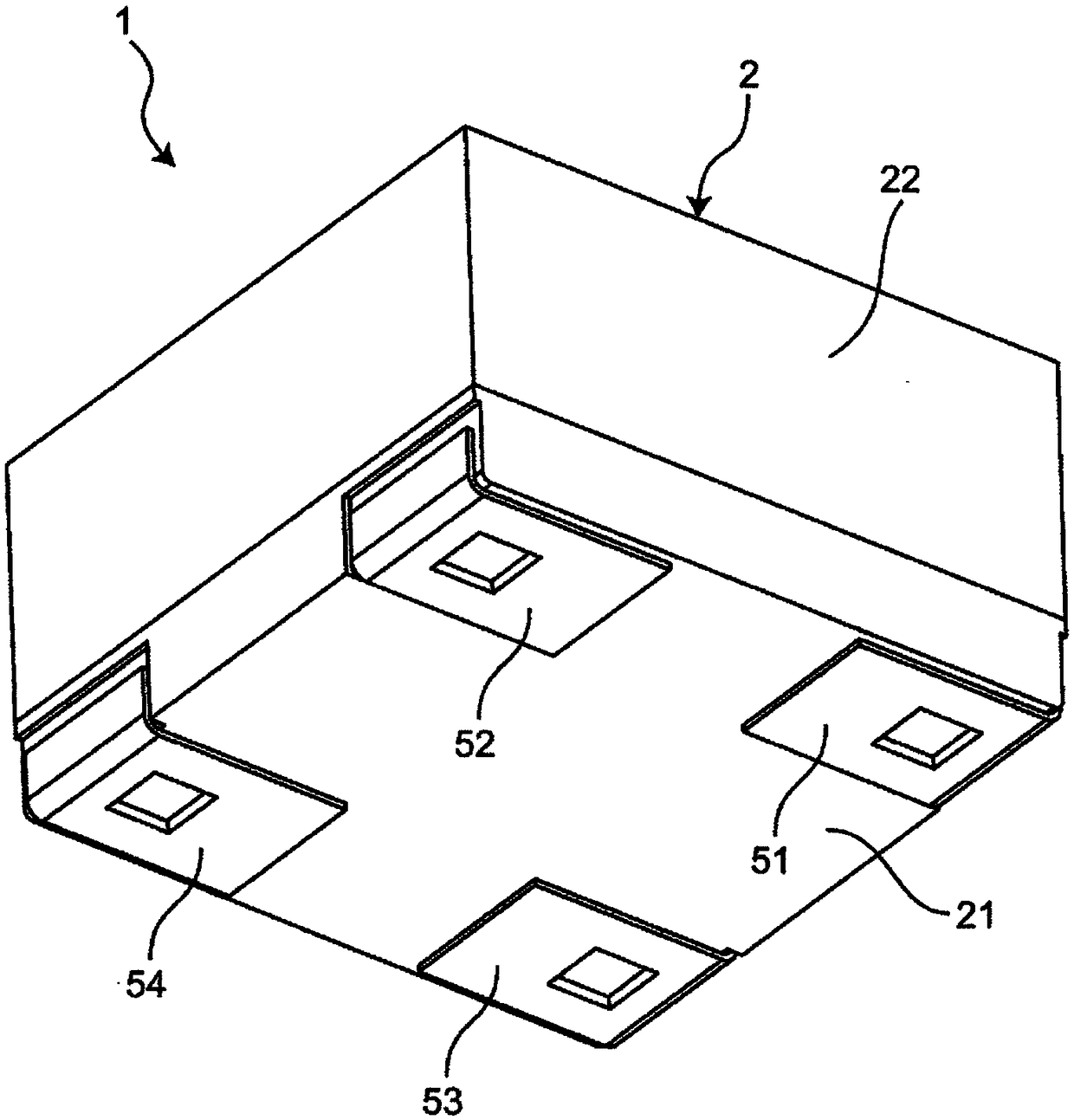

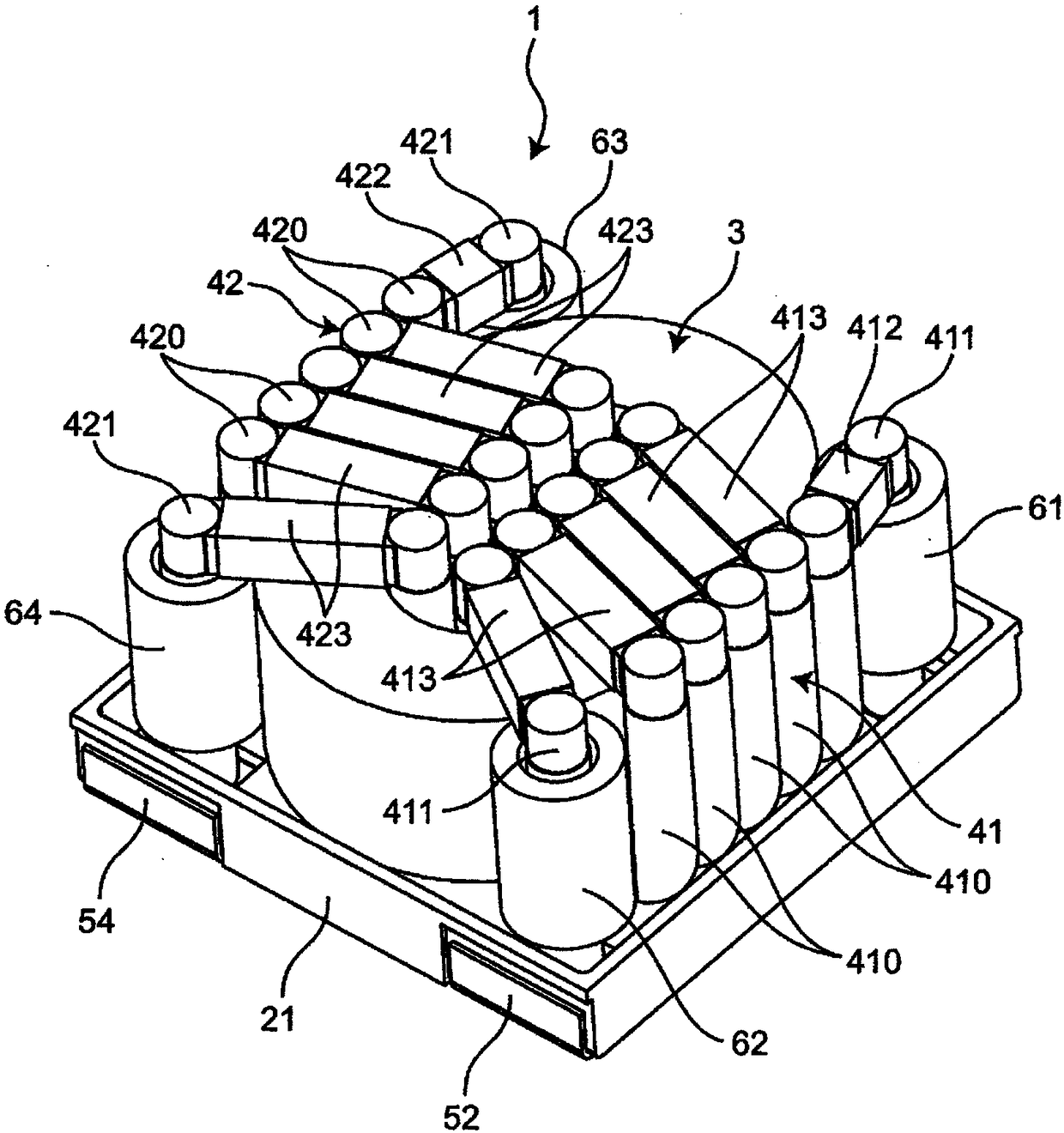

[0052] figure 1 It is an upper perspective view showing the common mode choke coil according to the first embodiment of the present invention. figure 2 It is the bottom perspective view of the common mode choke coil. image 3 It is an upper perspective view showing the inside of the common mode choke coil. Figure 4 It is an exploded perspective view of a common mode choke coil. Figure 5 is a top view of the common mode choke coil.

[0053] Such as Figure 1 to Figure 5 As shown, the common mode choke coil 1 has: a housing 2; an annular core 3 accommodated in the housing 2; a first coil 41 and a second coil 42 wound around the core 3 facing each other; and First to fourth ferrite beads 61 to 64 attached to the first coil 41 and the second coil 42 .

[0054] The housing 2 has a bottom plate portion 21 and a box-shaped cover portion 22 covering the bottom plate portion 21 . The casing 2 is made of, for example, resin such as PPS or ceramics. The core portion 3 is provi...

no. 2 approach

[0123] Figure 7 It is a plan view showing the second embodiment of the common mode choke coil of the present invention. The second embodiment differs from the first embodiment in the shape of the casing. This different configuration will be described below. In addition, in 2nd Embodiment, the same code|symbol as 1st Embodiment is the same structure as 1st Embodiment, Therefore The description is abbreviate|omitted.

[0124] like Figure 7 As shown, the shape of the casing 2A is rectangular when viewed from the direction of the central axis C of the core 3 . The shape of the core 3 is an elongated shape (in this embodiment, an oblong shape) as viewed from the direction of the central axis C of the core 3 . The core 3 is accommodated in the case 2A, and the direction of the major axis L of the core 3 is the same as the direction of the major axis of the case 2A. also, Figure 7 In , the drawing of coils and ferrite beads is omitted.

[0125] Therefore, since the core 3 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap