Efficient oil applying device for track bolt

An oiling device and bolt technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of heavy labor, many required personnel, and low efficiency, so as to reduce personnel, improve the degree of automation, The effect of improving oiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

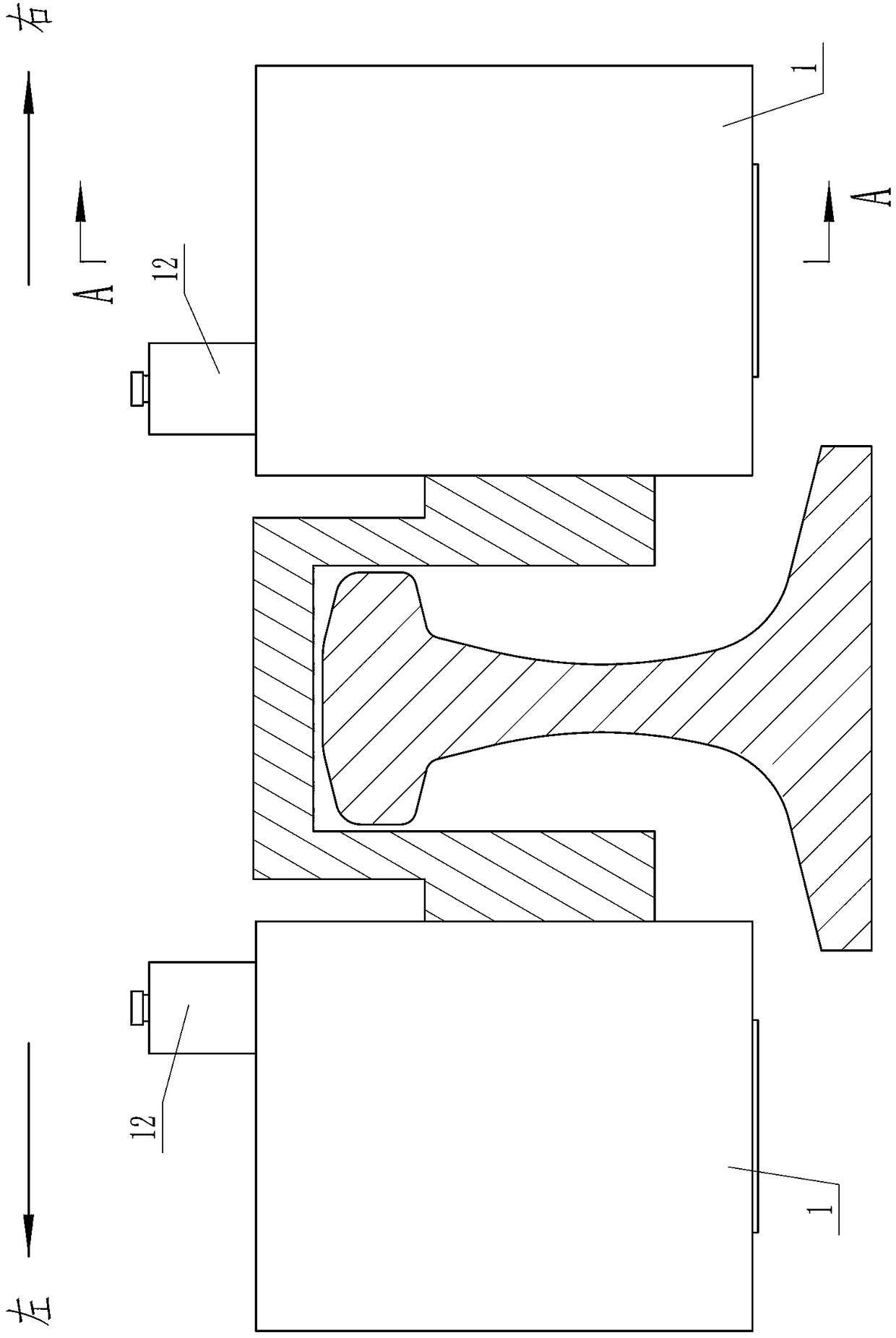

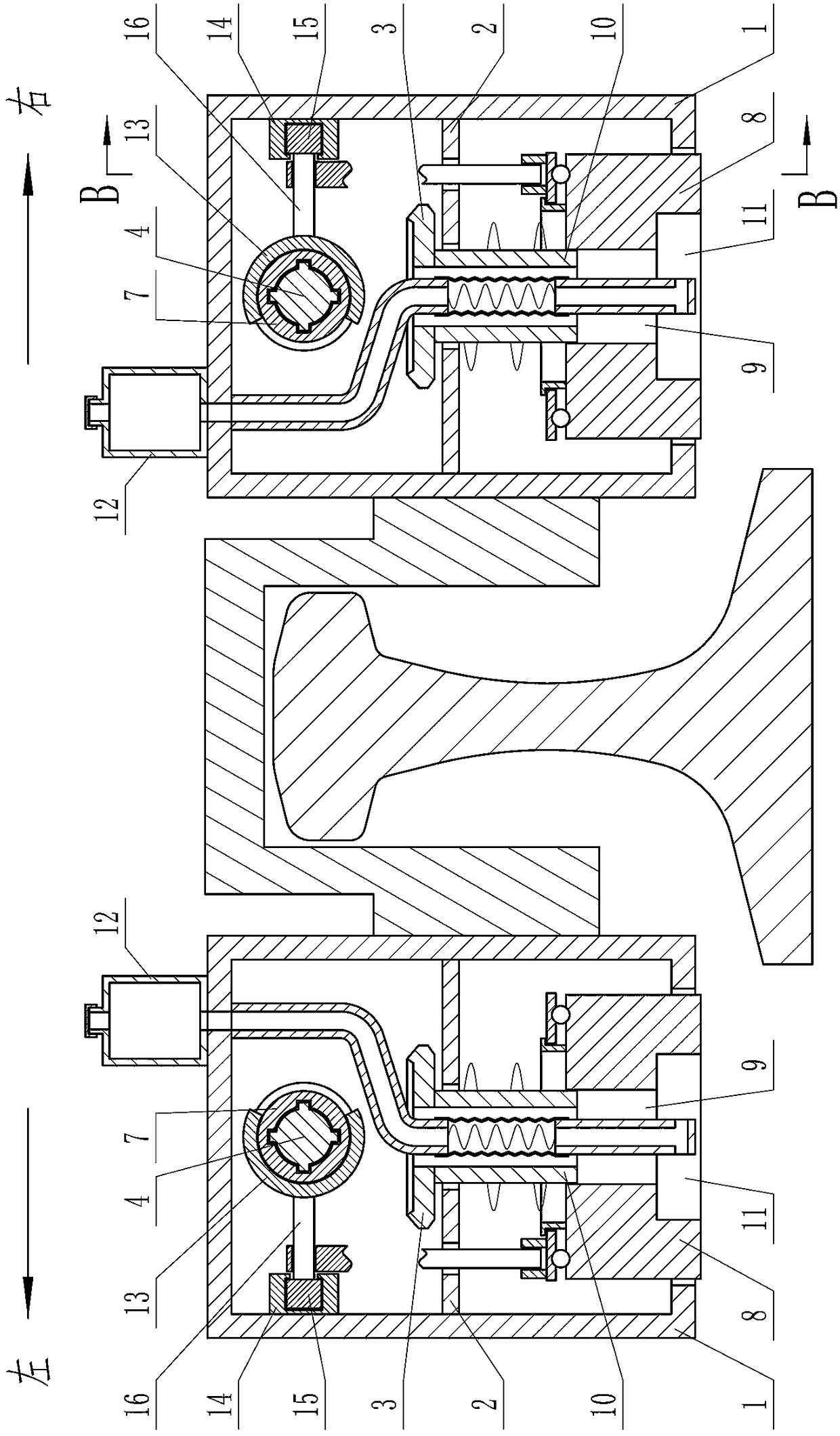

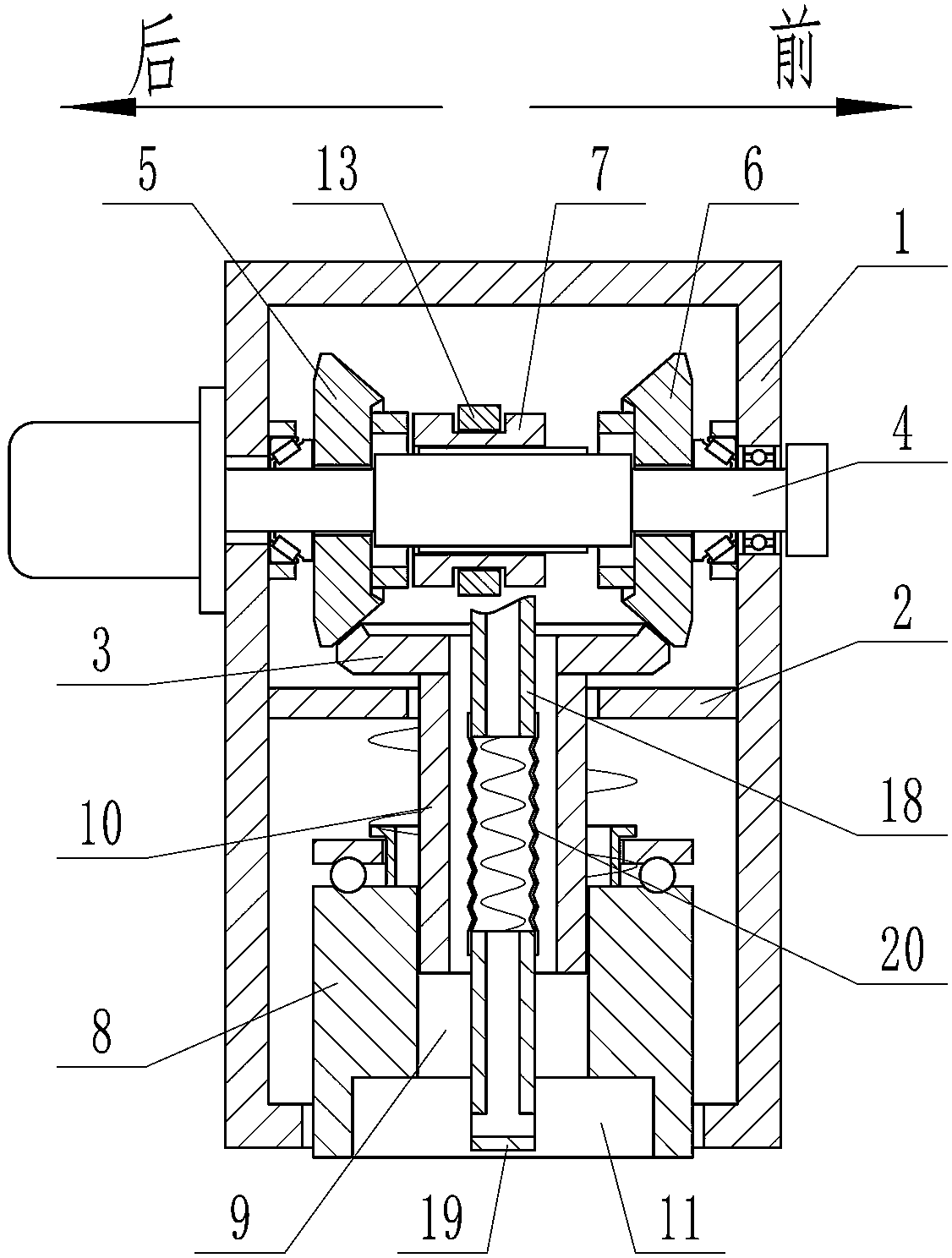

[0026] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] by Figure 1 to Figure 15 Given that the present invention includes a rectangular housing 1 placed horizontally, a flat plate 2 placed horizontally in the housing 1, a rotatable first bevel gear 3 on the upper end of the plate 2, and a horizontal and horizontal upper end of the first bevel gear 3 A rotating shaft 4 capable of actively rotating, a second bevel gear 5 meshing with the first bevel gear 3 is sleeved on the rotating shaft 4, a third bevel gear 6 meshing with the first bevel gear 3, and a second bevel gear 5 are sleeved on the rotating shaft 4 There is a gap between the second bevel gear 5 and the third bevel gear 6. Both the second bevel gear 5 and the third bevel gear 6 can rotate on the rotating shaft 4 but cannot move along the axial direction of the rotating shaft 4. The part of the rotating shaft 4 within the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com