Flexible vibrating disc

A vibrating plate, flexible technology, applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of high cost, weak vibration of vibrating plate, time-consuming disassembly and assembly, etc., to achieve convenient removal, reliable noise, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

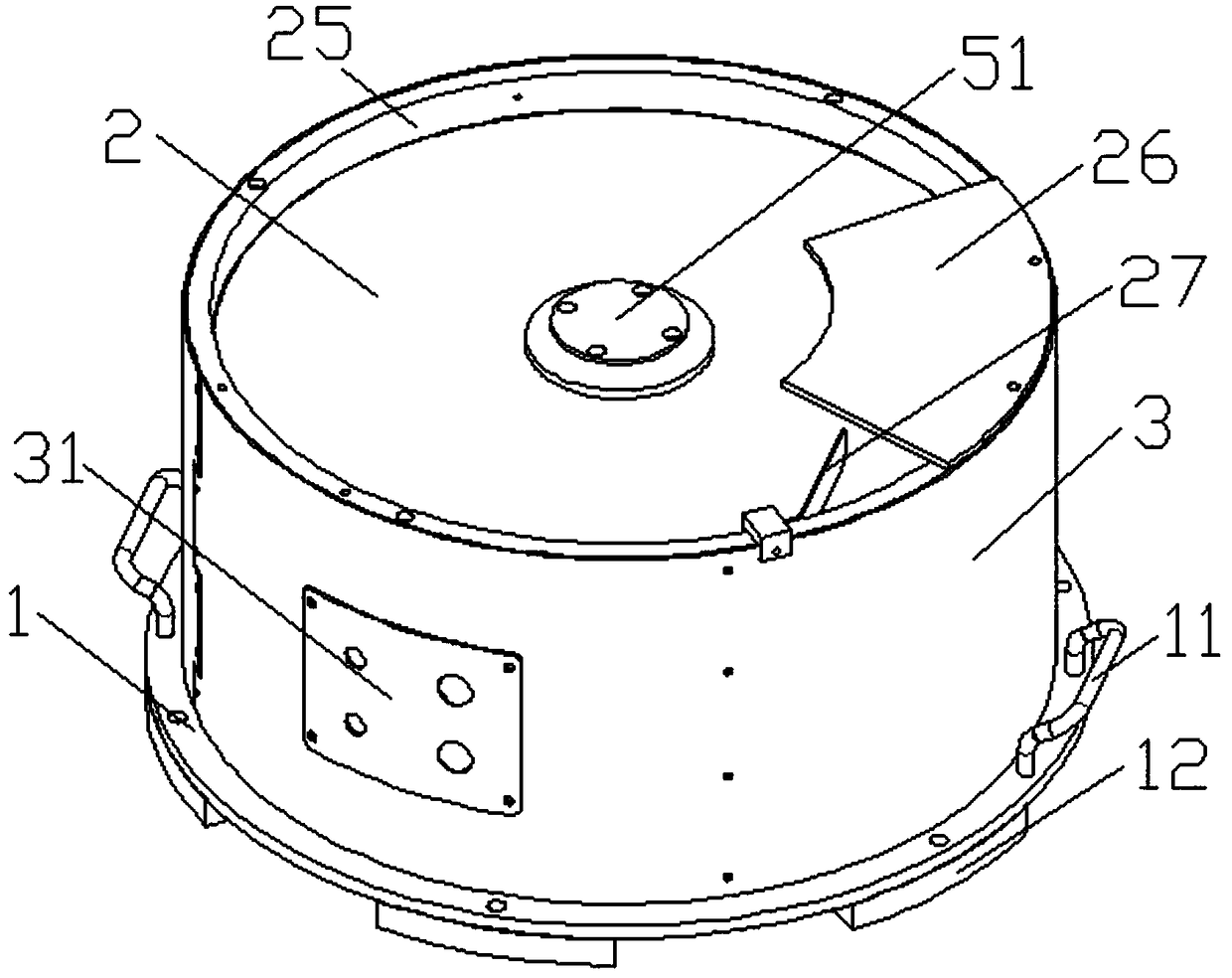

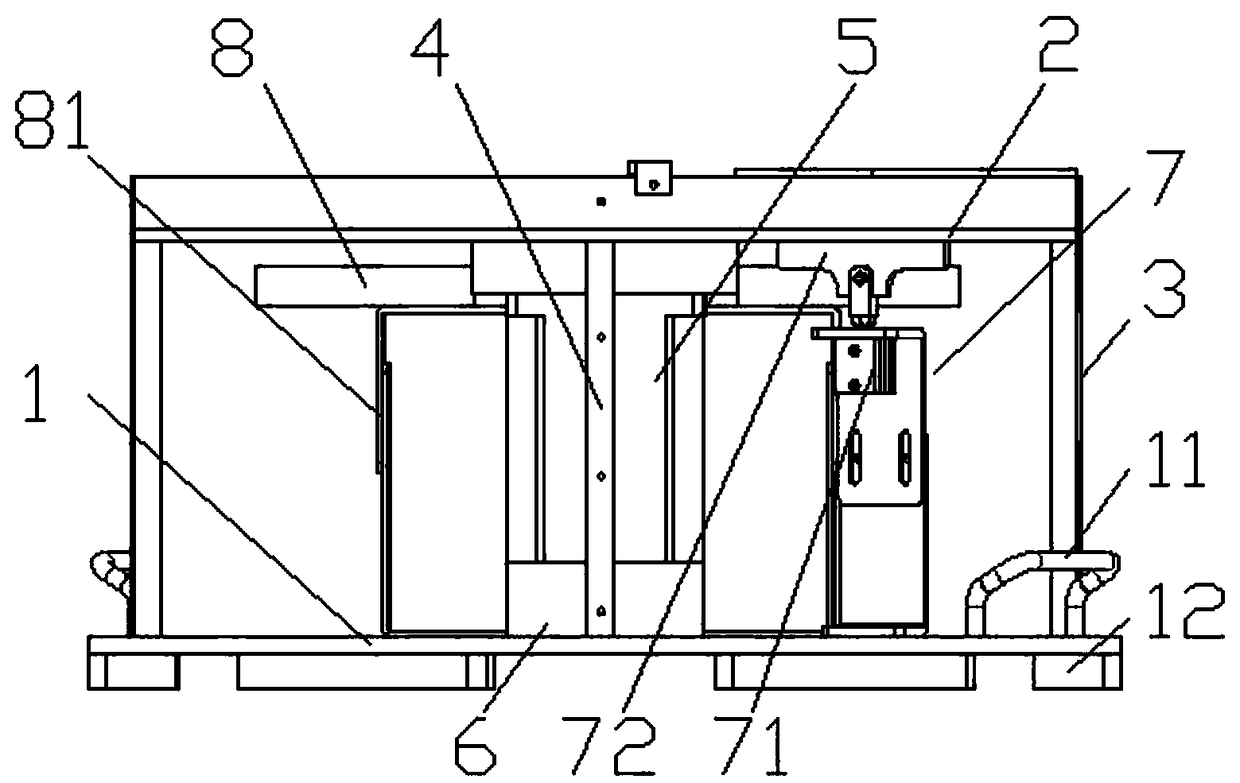

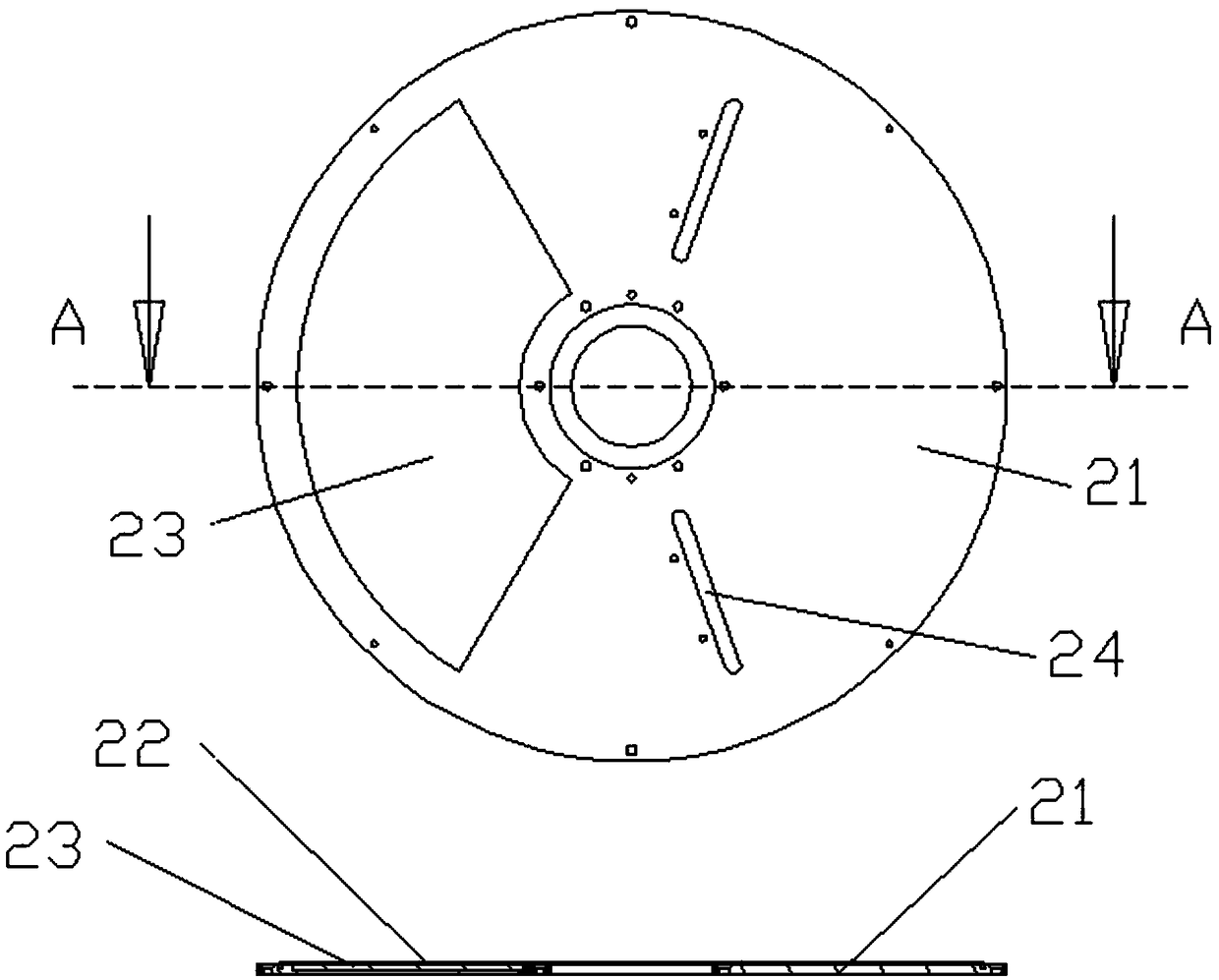

[0024] like Figure 1 to Figure 3 As shown, a flexible vibrating plate includes a bottom plate 1 and a tray 2 on the bottom plate 1. A protective cover 3 surrounds the periphery of the tray 2 to protect the parts below the tray 2. The protective cover 3 also An adapter plate 31 is provided to facilitate the extraction of cables. The material tray 2 is supported on the bottom plate 1 by the support rod 4. The motor 5, the driver 6, the pulse generator 7 and the backlight 8 are located under the material tray 2 and fixed on the bottom plate 1. A pair of handles 11 are arranged opposite to each other on the two ends of the base plate 1 to facilitate the movement of the flexible vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com