A fork pulling processing fixture of a hand-rocking lathe

A hand-operated, lathe technology, applied in the field of parts processing, can solve the problems of ordinary fixtures that are difficult to quickly clamp and take parts, low production efficiency, lack of lathe fork fixtures, etc., to improve labor productivity, flexible use, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

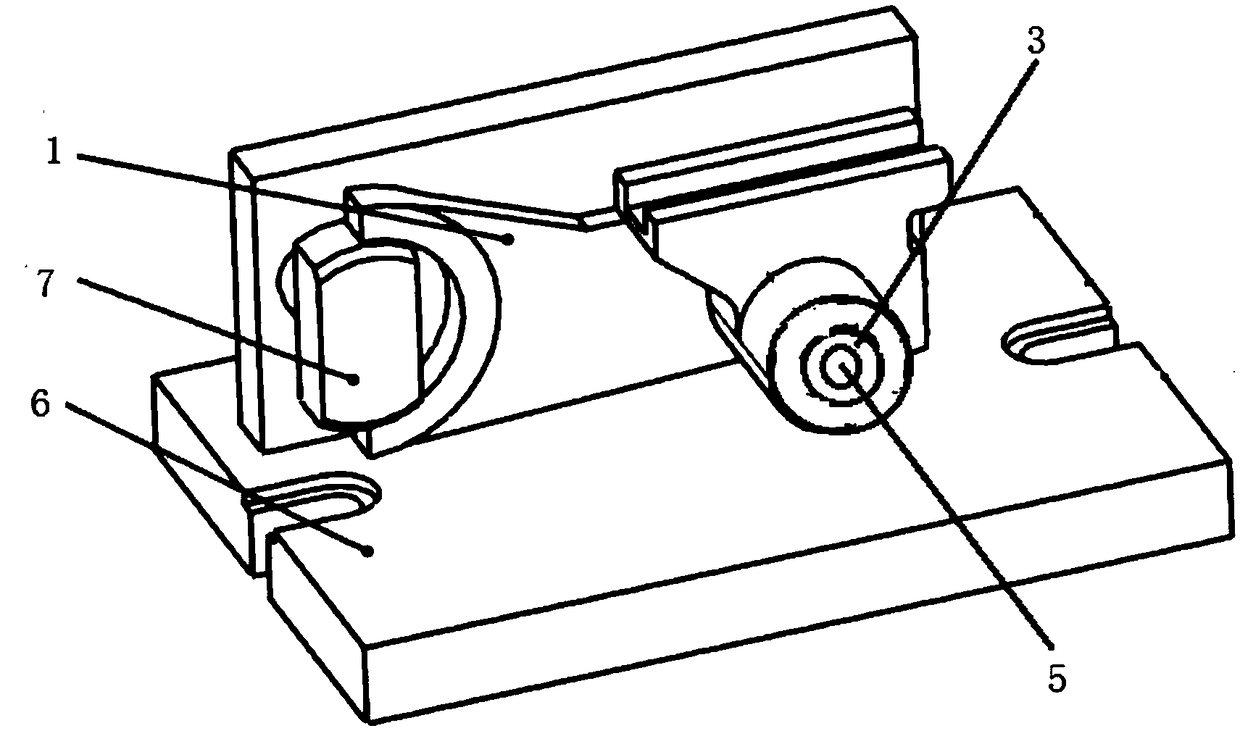

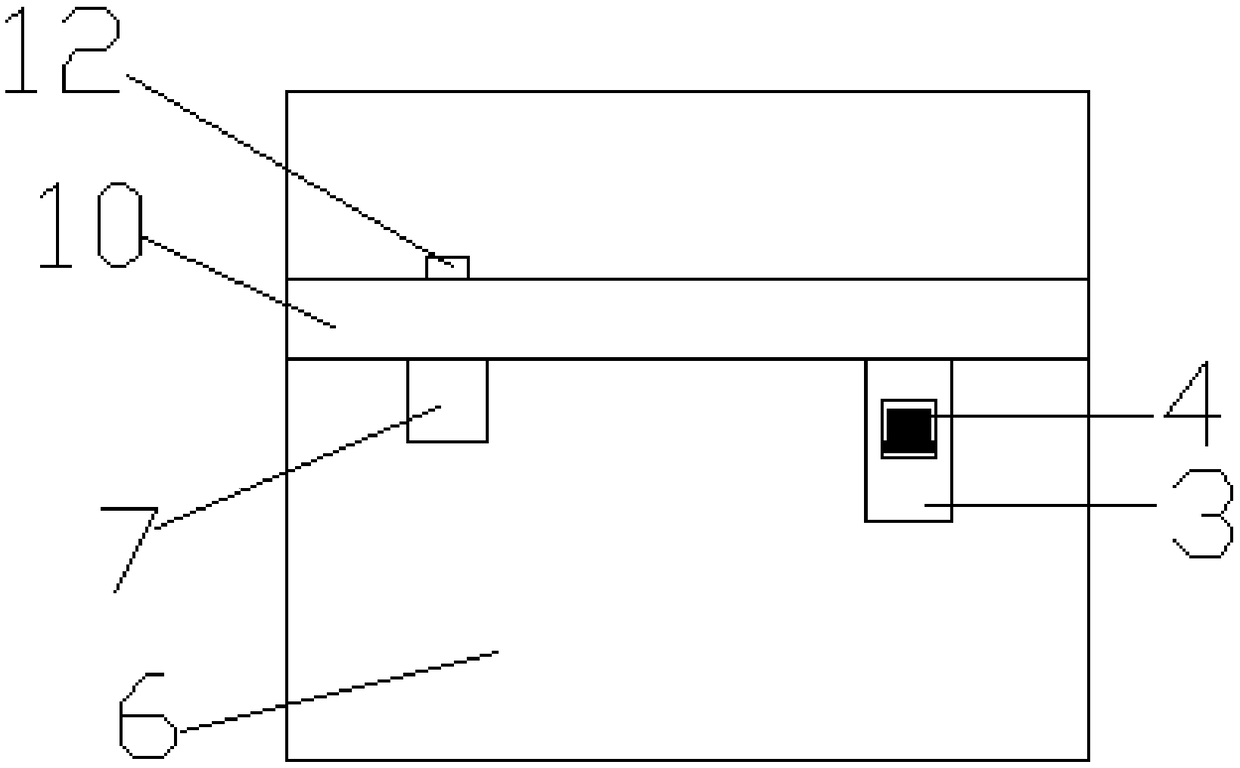

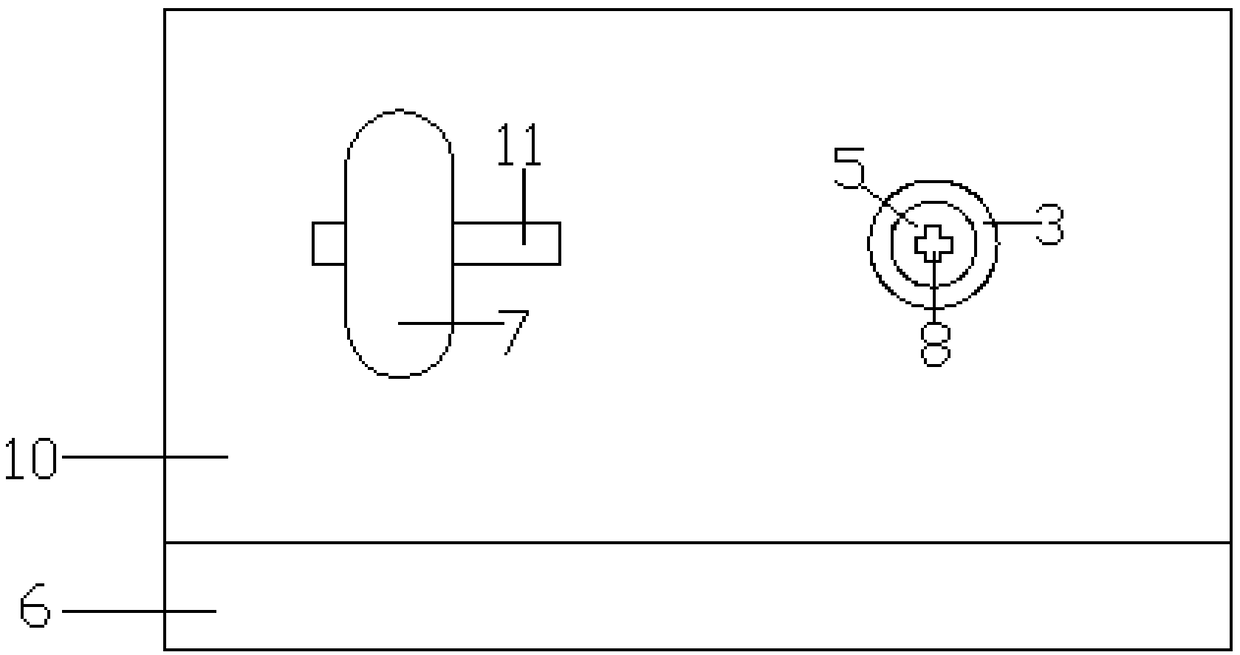

[0034] Embodiment 1. First, put the round mouth of the lathe fork 1 on the round mouth fixing cylinder 3, and then clamp the ring mouth on the ring mouth positioning pin 7. After the lathe fork is initially fixed, put the cross key rocker 2 The front cross key 20 is inserted into the cross lock 8 at the front end of the movable screw 5, and then the cross key rocker 2 is turned by hand to make the movable screw 5 rotate into the round mouth fixed cylinder 3, and the movable screw 5 moves into the round mouth fixed cylinder 3 for a while Touch the ball post 42 holding the fixed claw 4, and by pushing the ball post 42, the claw buckle 40 holding the fixed claw 4 will be lifted up, and it will be pushed against the round mouth of the lathe fork 1 to realize the fixation of the lathe fork 1 and clamping.

Embodiment 2

[0035] Embodiment 2. Since the fixing bolt 12 is threadedly connected with the ring opening positioning pin 7 through the bolt through groove 11, the ring opening positioning pin 7 can be fine-tuned on the middle plate 10 through the fixing bolt 12, so it can be better started. Due to the function of fixing the fork 1 of the lathe, the rotating shaft 41 of the clamping and fixing claw 4 is rotationally connected with the cylinder wall of the round mouth fixing cylinder 3. Therefore, after the ball post 42 is pushed, the clamping and fixing claw 4 will be centered on the rotating shaft 41. Rotation, clamping and fixing claw 4 rotations can make claw button 40 turn out from the claw button groove 30, thereby play fixing and clamping effect, abutment 6 bottom end is provided with leg to facilitate the movement and placement of abutment 6.

[0036] Based on the above, the present invention is simple in structure and flexible in use. The initial fixation of the lathe shift fork is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com