Barrel-conveying vehicle

A technology of transport vehicles and oil drums, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of time-consuming, labor-intensive, inconvenient use, etc., and achieve the effect of reducing operation intensity, improving work efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

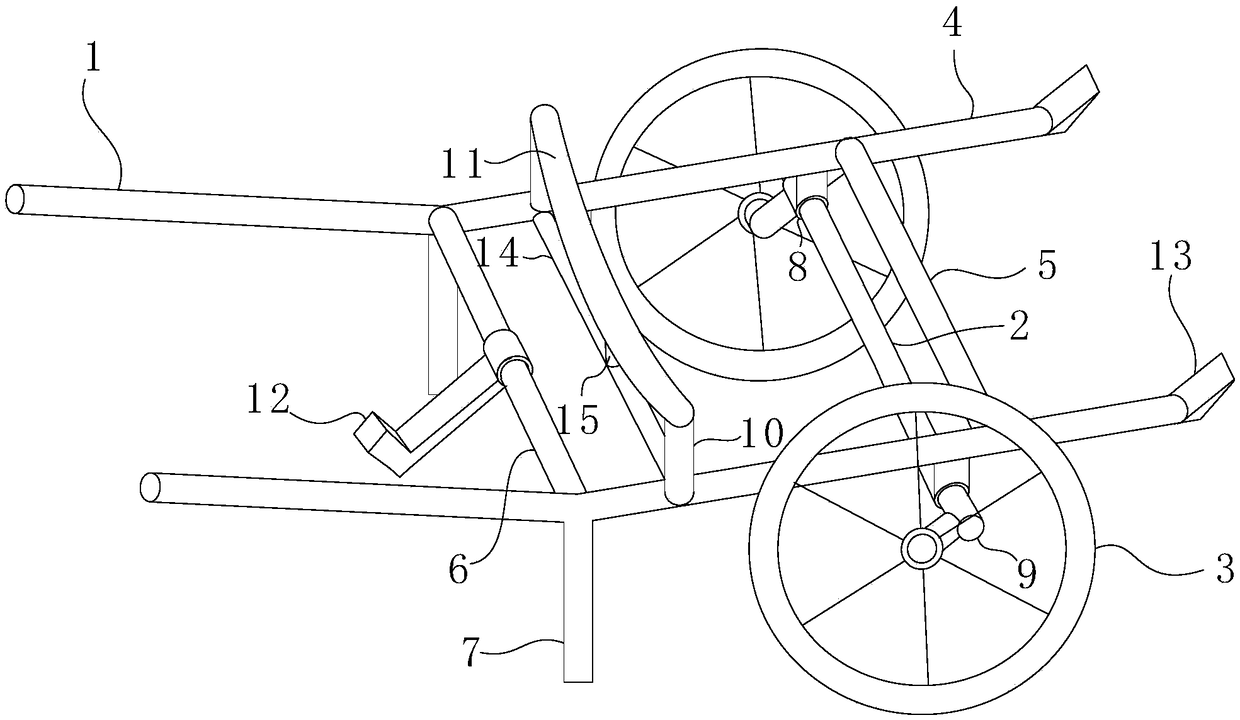

[0014] As shown in the figure, the present invention includes: a vehicle frame, a handlebar 1 installed on the vehicle frame, a wheel shaft 2 and a wheel 3, the vehicle frame includes two longitudinal beams 4, a middle beam 5 and a rear beam 6, the The two ends of the middle beam are respectively affixed to the middle of the two longitudinal beams, the two ends of the rear beam are respectively affixed to the ends of the two longitudinal beams close to the handlebar, and the two ends of the rear beam are affixed with downward legs 7, The bottom ends of the middle parts of the two longitudinal beams are fixedly connected with bushings 8 respectively. The axles pass through the two bushings and cranks 9 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com