Detachable open type invisible protective net

A protective net and open technology, which is applied in the direction of shutters/movable grilles, etc., can solve the problems of reducing the survival rate of personnel, high use and maintenance costs, and reduced strength and toughness, so as to reduce the use cost and maintenance cost, and facilitate The effect of using and maintaining and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

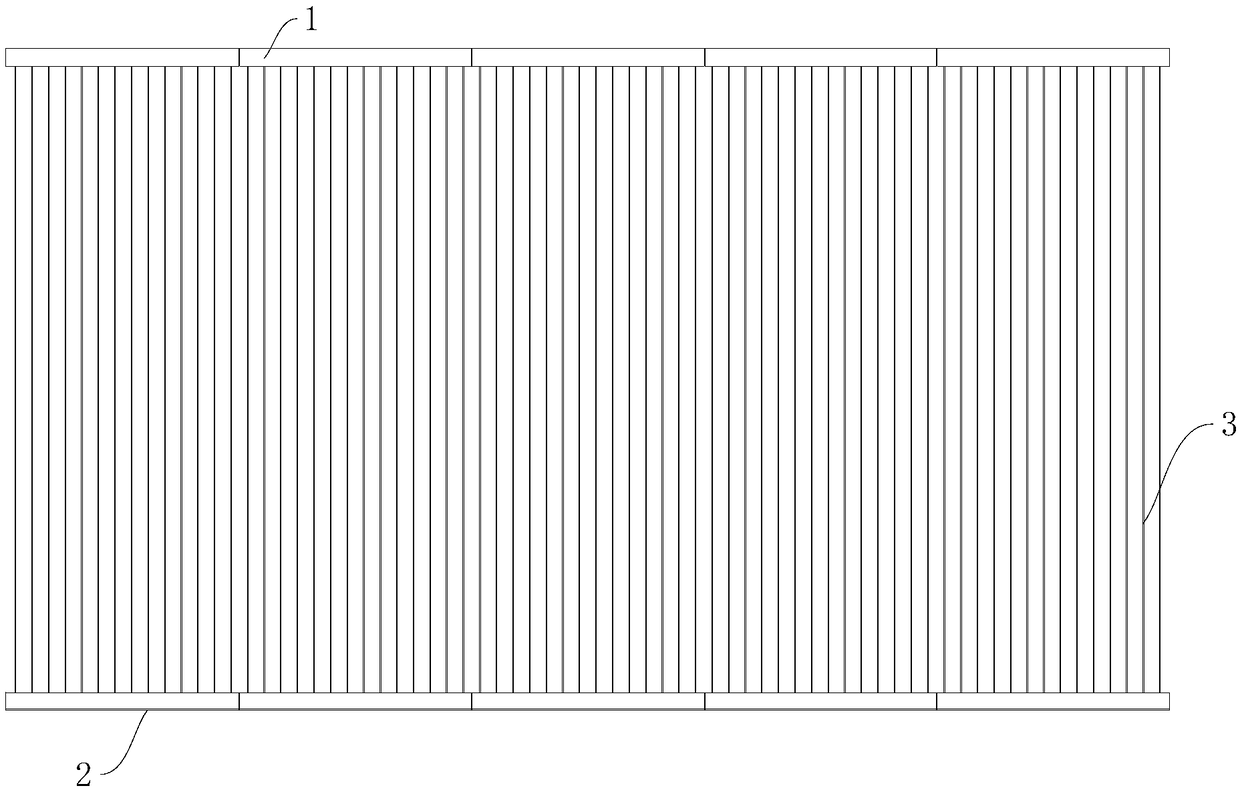

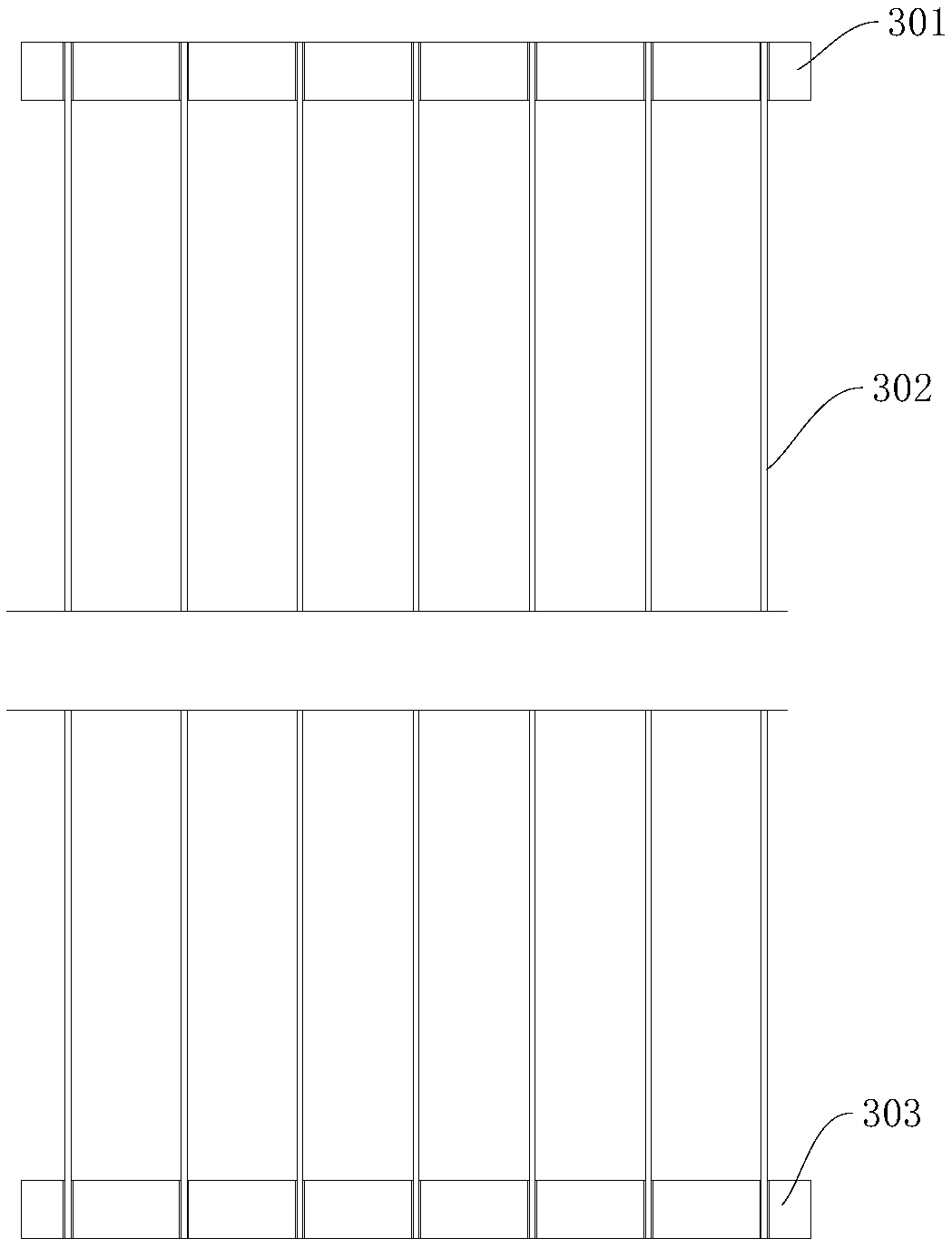

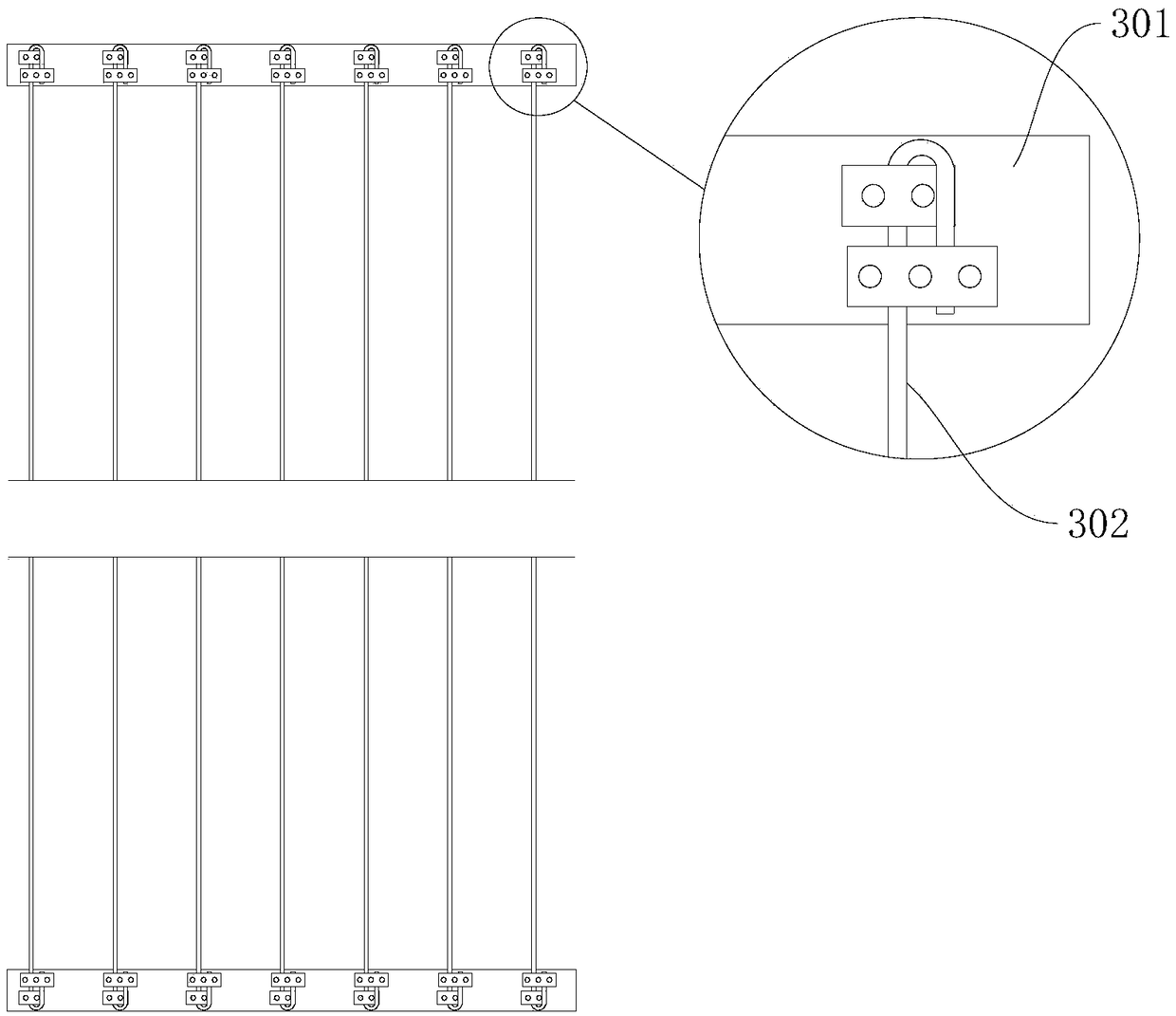

[0043] like figure 1 , figure 2 , image 3 As shown, this embodiment discloses a detachable and openable invisible protective net, comprising an upper frame rail 1, a lower frame rail 2 and a web, and the upper and lower ends of the web spokes 3 are connected to the upper frame rail 1 and the lower frame respectively. The rail 2 is connected; specifically, the upper frame rail 1 includes an upper main profile, and the upper main profile includes an upper connecting portion 402 for fixing itself, and is used for connecting the upper body 4 of the hanging groove member 7 , The upper body 4 is connected to the hanging groove part 7 by bolts.

[0044] The lower frame rail 2 includes a lower main profile, and the lower main profile includes a lower connection part 902 for fixing itself, a lower body 9 connected with the lower connection part 902, and a bearing groove connected with the lower body 9 , and an abutment structure 12 connected to the lower body 9 and located above t...

Embodiment 2

[0065] like figure 1 , figure 2 , image 3 As shown, this embodiment discloses a detachable and openable invisible protective net, comprising an upper frame rail 1, a lower frame rail 2 and a web, and the upper and lower ends of the web spokes 3 are connected to the upper frame rail 1 and the lower frame respectively. Rail 2 connection. Specifically, the upper frame rail 1 includes an upper main profile, and the upper main profile includes an upper connecting portion 402 for fixing itself, an upper body 4 for connecting the hanging groove member 7, and an upper body 4 The hanging groove part 7 is connected by bolts.

[0066] The lower frame rail 2 includes a lower main profile, and the lower main profile includes a lower connection part 902 for fixing itself, a lower body 9 connected with the lower connection part 902, and a bearing groove connected with the lower body 9 , and an abutment structure 12 connected to the lower body 9 and located above the bearing groove.

...

Embodiment 3

[0085] like figure 1 , figure 2 , image 3 As shown, this embodiment discloses a detachable and openable invisible protective net, comprising an upper frame rail 1, a lower frame rail 2 and a web, and the upper and lower ends of the web spokes 3 are connected to the upper frame rail 1 and the lower frame respectively. The rail 2 is connected; specifically, the upper frame rail 1 includes an upper main profile, and the upper main profile includes an upper connecting portion 402 for fixing itself, and is used for connecting the upper body 4 of the hanging groove member 7 , The upper body 4 is connected to the hanging groove part 7 by bolts.

[0086] The lower frame rail 2 includes a lower main profile, and the lower main profile includes a lower connection part 902 for fixing itself, a lower body 9 connected with the lower connection part 902, and a bearing groove connected with the lower body 9 , and an abutment structure 12 connected to the lower body 9 and located above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com