Cyclone redistribution denitration reactor for flue gas

A denitrification reactor, distributed technology, applied in gas treatment, separation method, dispersed particle separation and other directions, can solve the problems of flue gas distribution dead angle, uneven mixing of ammonia gas, affecting denitration efficiency, etc., to improve the uniformity of mixing, The effect of reducing the probability of blockage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

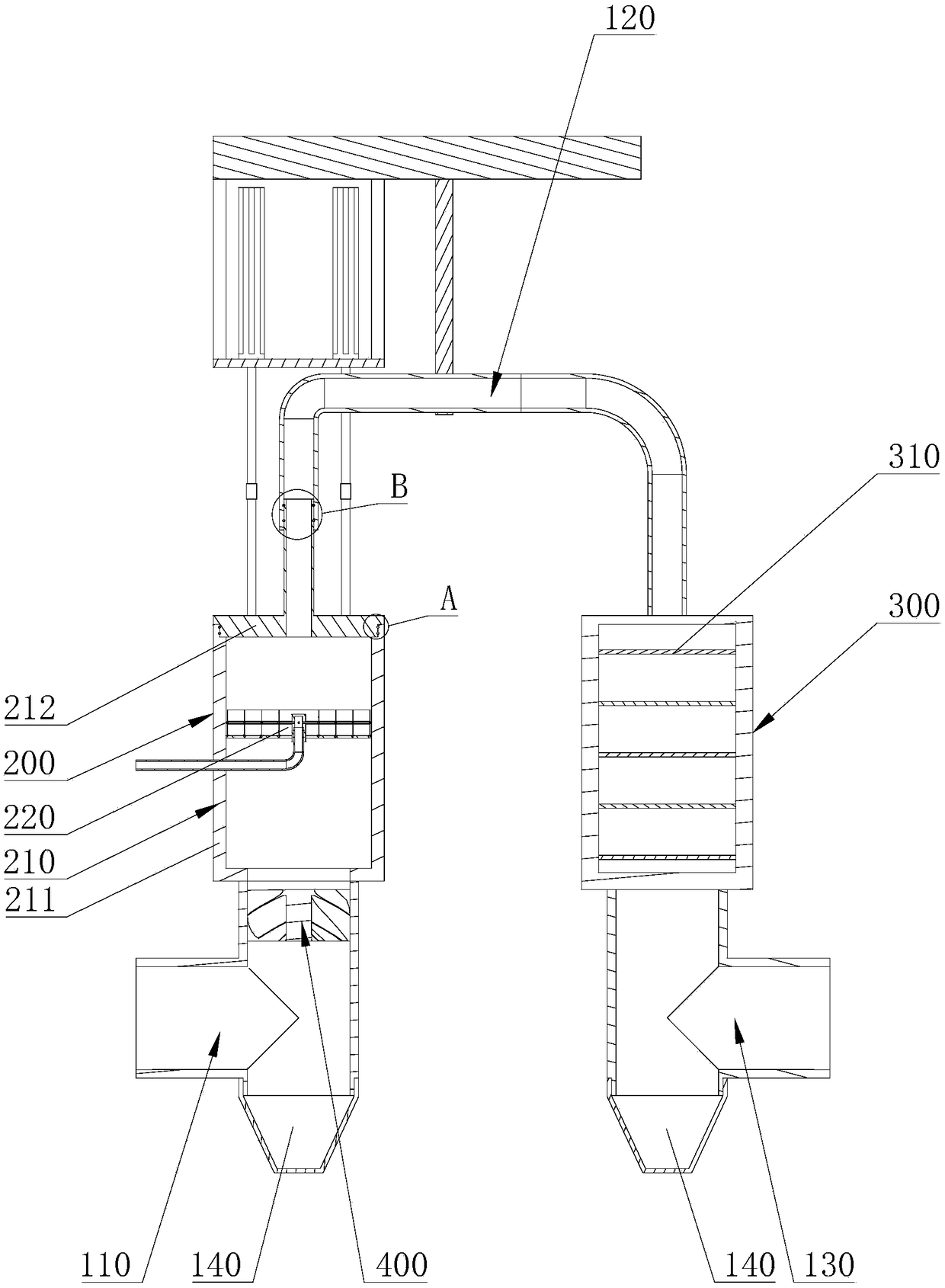

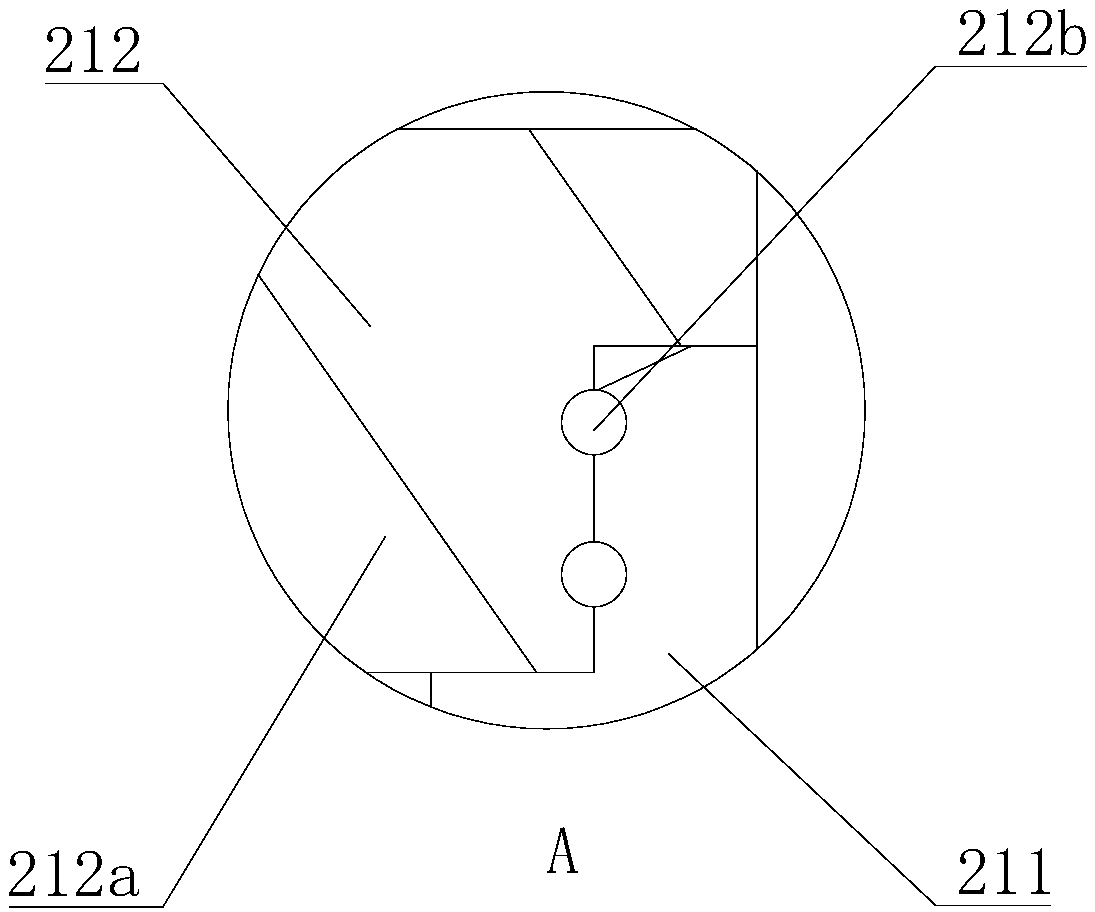

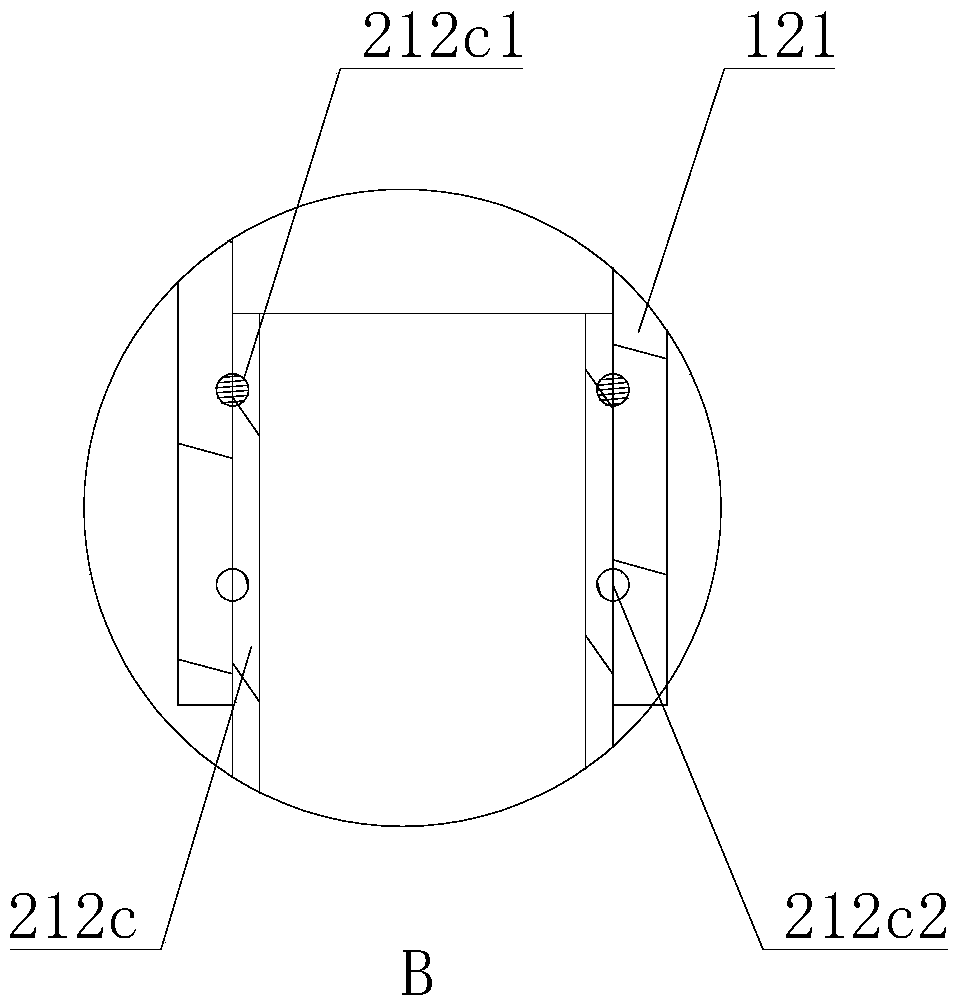

[0046] See attached figure 1 , a flue gas swirling redistributed denitrification reactor, comprising a flue gas inlet pipe 110, an ammonia injection mixing device 200 connected to the flue gas inlet pipe 110, a catalytic reaction device 300, and a catalytic reaction device connected to the ammonia injection mixing device 200 The connecting flue pipe 120 between the devices 300 and the flue gas outlet pipe 130 connected with the catalytic reaction device 300 . The flue gas sequentially passes through the flue gas inlet pipe 110, the ammonia injection mixing device 200, the connecting flue gas pipe 120, and the catalytic reaction device 300, and finally leaves the entire flue gas swirling and distributed denitrification reactor from the flue gas outlet pipe 130, wherein the flue gas The ammonia injection mixing device 200 is mixed with the flue gas, and the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com