Furnace comprising conveying device

A conveying device, oven technology, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of sagging, low productivity, low efficiency, etc., and achieve the effect of avoiding deviation from position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

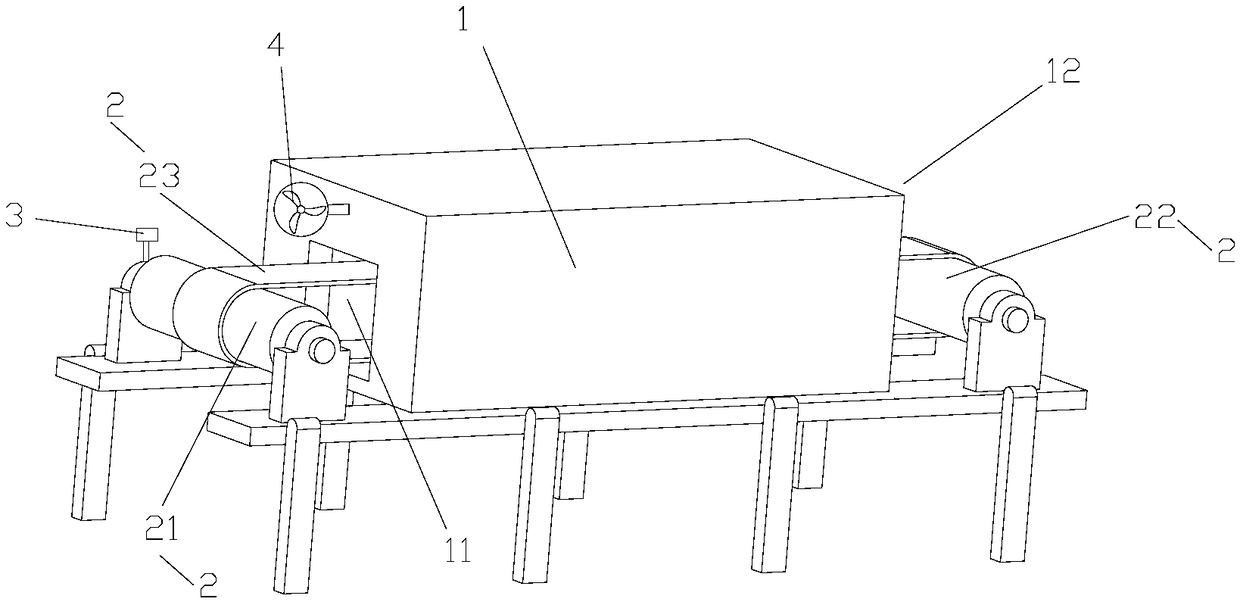

[0017] like figure 1 As shown, in this embodiment, an oven with a conveying device includes a furnace body 1 and a conveying device 2. The furnace body is provided with a furnace chamber, a heating device is provided in the furnace chamber, and the furnace body is provided with an inlet 11 and an outlet 12. The device 2 passes through the furnace body 1 and starts at the inlet 11 and ends at the outlet 12 .

[0018] The conveying device 2 is a driving wheel 21, a driven wheel 22, and a conveyor belt 23; the driving wheel 21 and the driven wheel 22 are respectively arranged at both ends of the furnace body 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com