Improved wind tunnel test mechanism for model placement and separation

A wind tunnel test and an improved technology, which is applied in the field of aerospace engineering, can solve problems such as rope lengthening, affecting the free movement of bullets or shells, and frictional resistance, so as to reduce the influence of free movement, shorten the relative movement length, The effect of preventing the tool from being out of position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

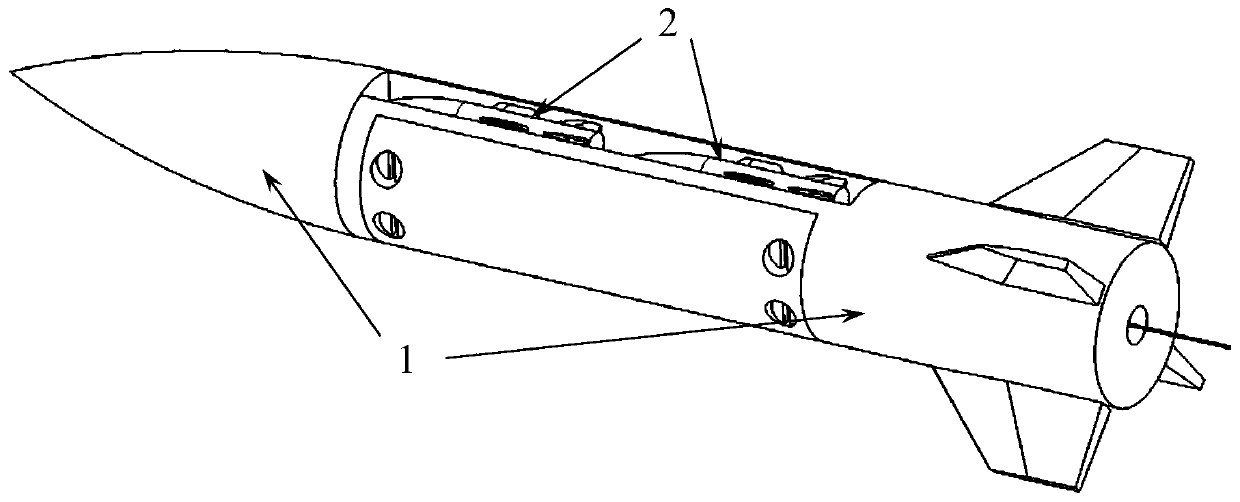

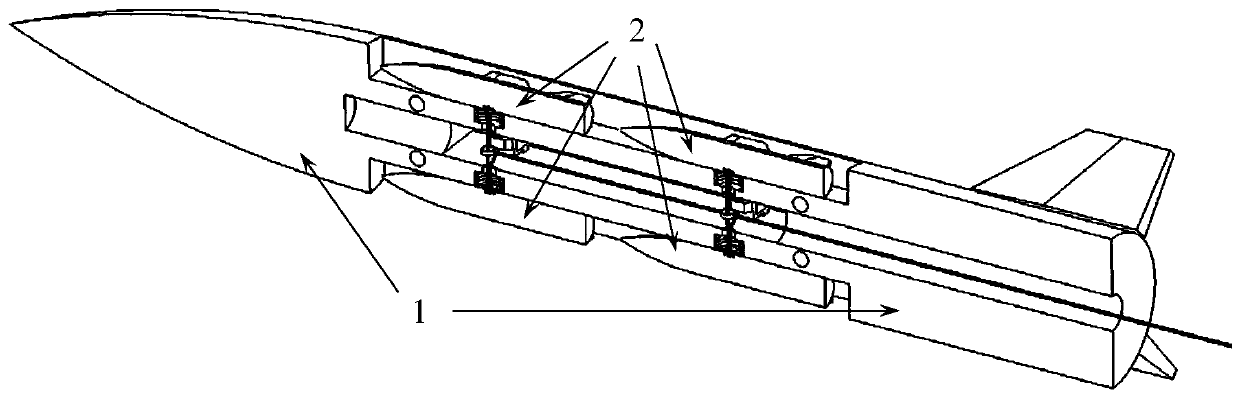

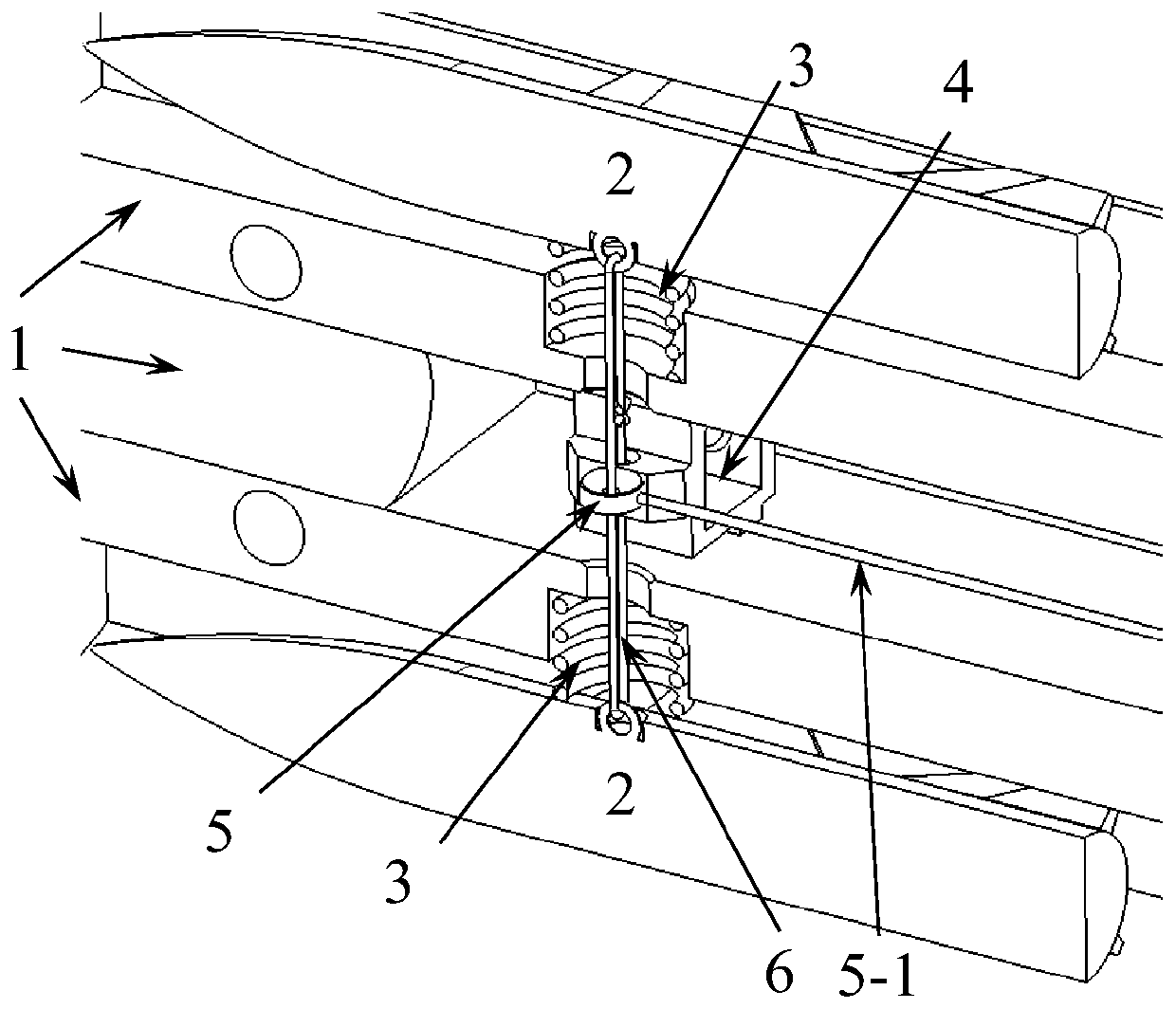

[0040] see Figure 1 to Figure 10 As shown: the bullets 2 are distributed on both sides of the mother bullet 1, and the distribution is symmetrical. Such as Figure 8 As shown, bullet groove 1-1 is symmetrically designed along the axial direction of female bullet 1; spring blind hole 1-2 is processed radially from the bullet groove along the female bullet, and a tightening block groove is designed in the axial direction perpendicular to the spring blind hole of female bullet , from the bottom of the spring blind hole 1-2, pass through the tightening block groove and process the binding rope through hole 1-3. Such as Figure 9 As shown, the main body of the tightening block 4 is a hollow quadrilateral structure, and one side of the quadrangle is processed with tightening block threaded holes 4-3, and a boss is arranged on the outer end surface of the side opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com