Anti-scouring aerogel composite material and preparation method thereof

A composite material and aerogel technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of difficult control of profile accuracy, increase the complexity of the process, and increase the cost, and achieves a reduction in Punching and sewing process, reducing the risk of delamination, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

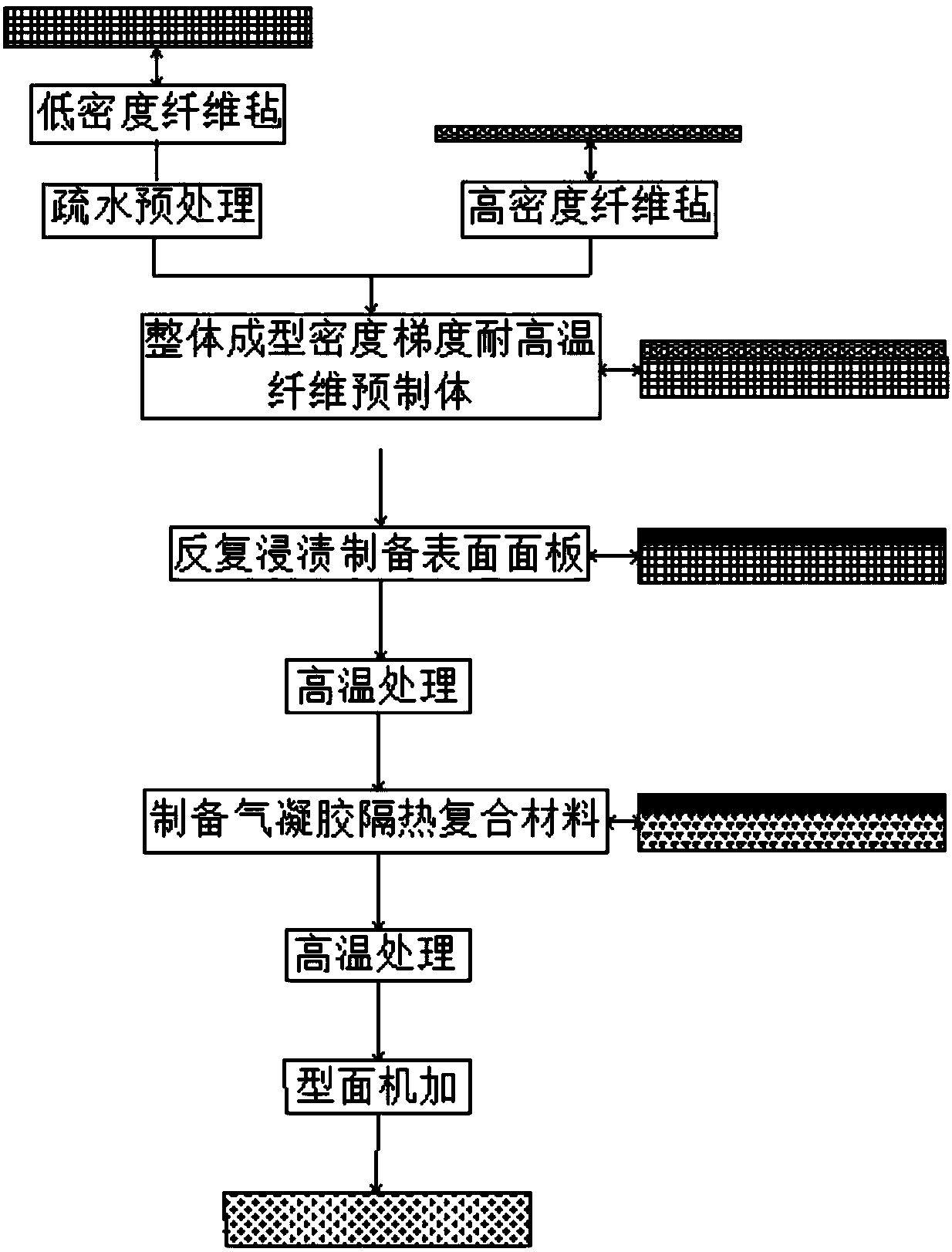

Method used

Image

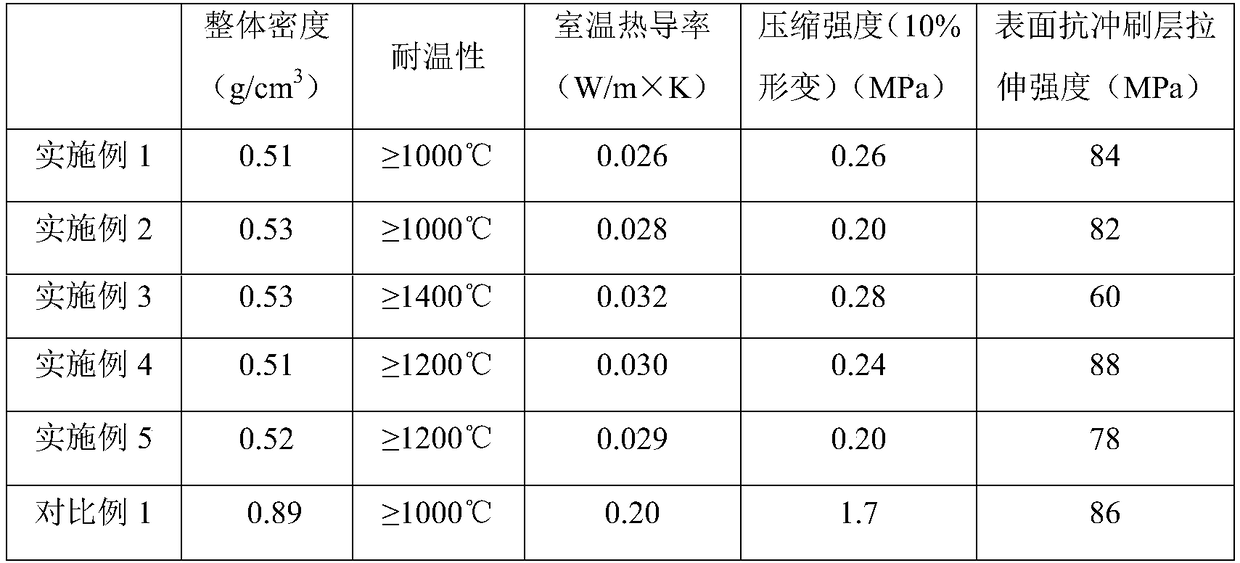

Examples

Embodiment 1

[0051] 1) The selected density is 0.70g / cm 3 , the mullite fiber felt with a thickness of 1mm is a high-density fiber felt, and the selected density is 0.10g / cm 3 , The quartz fiber felt with a thickness of 24mm is a low-density fiber felt.

[0052] 2) Firstly, methyltrimethoxysilane is used to hydrophobically treat the quartz fiber mat, and then the quartz fiber mat and mullite fiber mat are prepared into a high-temperature-resistant fiber preform with an integral density gradient by needle punching. The needle punching density is 15 stitches / cm 2 .

[0053] 3) Place the prefabricated body in a closed container, impregnate the composite mullite fiber mat with the silica sol by vacuum impregnation, repeat the impregnation 9 times, and then perform high temperature treatment to remove organic matter.

[0054] 4) The surface-strengthened prefabricated body is impregnated with silica sol, and after aging, supercritical drying and other processes, an airgel thermal insulation c...

Embodiment 2

[0058] 1) The selected density is 0.70g / cm 3 , the mullite fiber felt with a thickness of 1mm is a high-density fiber felt, and the selected density is 0.10g / cm 3 , The quartz fiber felt with a thickness of 24mm is a low-density fiber felt.

[0059] 2) First, use methylphenyl silicone resin solution to hydrophobically treat the quartz fiber mat, and then prepare the quartz fiber mat and mullite fiber mat by needling to form an integral high-temperature-resistant fiber preform with a density gradient. 15 stitches / cm 2 .

[0060] 3) Place the prefabricated body in a closed container, impregnate the composite mullite fiber mat with the silica sol by vacuum impregnation, repeat the impregnation 9 times, and then perform high temperature treatment to remove organic matter.

[0061] 4) The surface-strengthened prefabricated body is impregnated with silica sol, and after aging, supercritical drying and other processes, an airgel thermal insulation composite material with a density...

Embodiment 3

[0065] 1) The selected density is 0.70g / cm 3 , the silicon carbide fiber felt with a thickness of 1mm is a high-density fiber felt, and the selected density is 0.10g / cm 3 , The mullite fiber felt with a thickness of 24mm is a low-density fiber felt.

[0066] 2) First, use methyltrimethoxysilane to hydrophobically treat the mullite fiber mat, and then prepare the mullite fiber mat and the silicon carbide fiber mat by needling to form an integral high-temperature-resistant fiber preform with a density gradient. Puncture density is 15 needles / cm 2 .

[0067] 3) Place the prefabricated body in a closed container, impregnate the composite mullite fiber mat with the mullite sol by vacuum impregnation, repeat the impregnation 9 times, and then perform high temperature treatment to remove organic matter.

[0068] 4) The surface-strengthened prefabricated body is impregnated with mullite sol, and after aging, supercritical drying and other processes, an airgel thermal insulation com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com