A method for manufacturing an ultra-long thin-walled aluminum alloy sandwich rib double-skin integral empennage

A manufacturing method and aluminum alloy technology, applied in the field of mechanical processing and manufacturing, can solve problems such as poor quality stability of structural castings and imperfect precision casting molding methods, and achieve the effects of shortening the manufacturing cycle, reducing manufacturing costs, and ensuring overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiment of the present application improves the quality and precision of the product by providing a manufacturing method of an ultra-long thin-walled aluminum alloy sandwich grid rib double-skin integral empennage.

[0064] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embodiments can be combined without conflict.

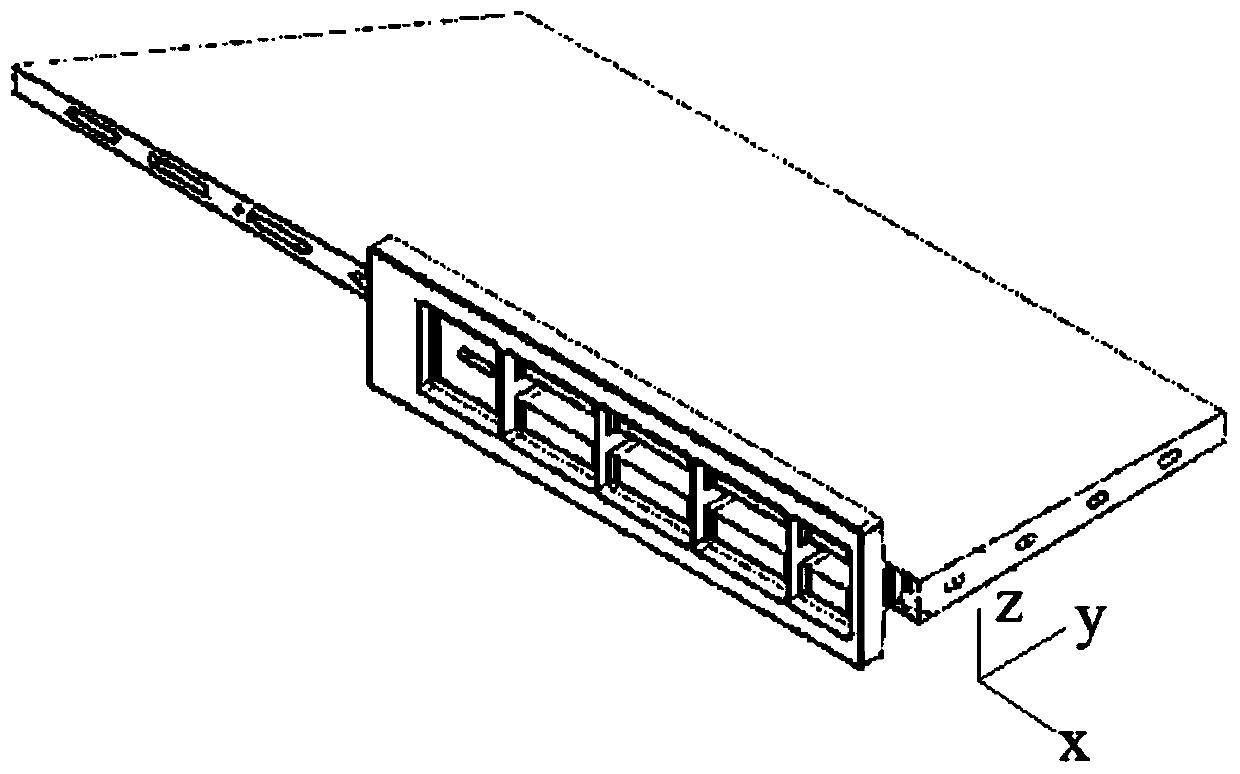

[0065] see figure 1 , a method for manufacturing an ultra-long thin-walled aluminum alloy sandwich rib double-skin integral empennage, comprising:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com