Honeycomb supporting structure comprising flexible skin and preparation method of flexible skin

A support structure, honeycomb technology, used in chemical instruments and methods, transportation and packaging, synthetic resin layered products, etc., to achieve the effect of reducing output requirements, maintaining aerodynamic shape, and uniform surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

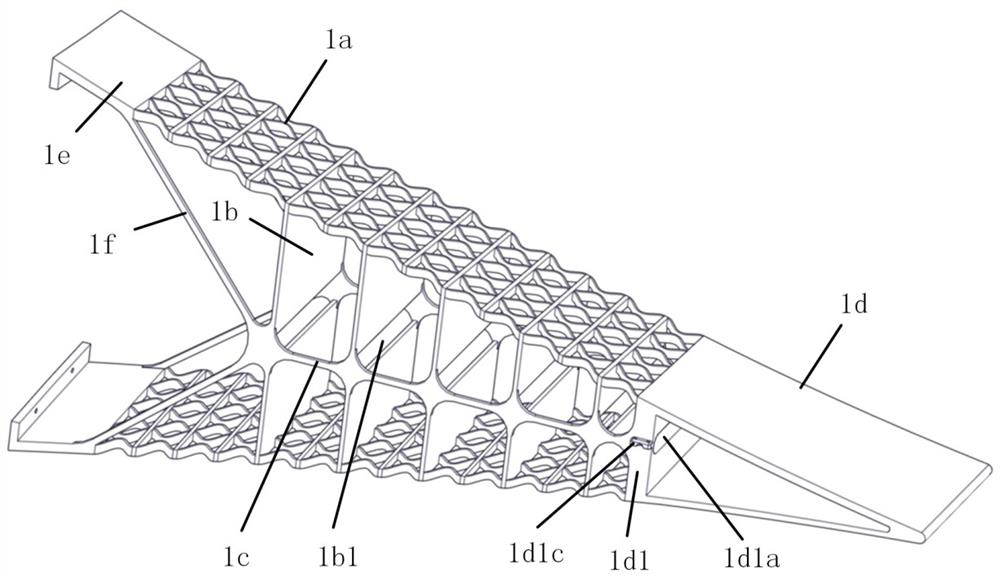

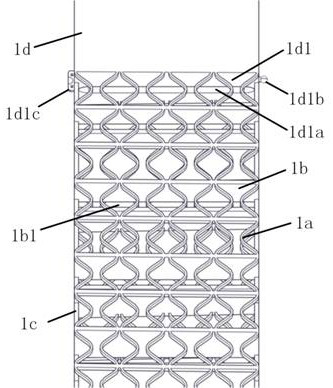

[0029] The webs 1b are arranged spanwise between the zero Poisson's ratio honeycombs 1a on the upper and lower surfaces, and a through groove 1b1 is provided in the middle of each web 1b. The central side strip 1c is arranged at the height center position of the side of the web 1b, and is fixedly connected with all the webs 1b. The trailing edge section 1d is fixedly connected with the zero Poisson's ratio honeycomb 1a and the central side strip 1c. The zero Poisson's ratio honeycomb 1a is fixedly connected to the leading edge installation section 1e. Both ends of the inclined side tie rod 1f are fixedly connected to the front edge installation section 1e and the central side strip 1c respectively. The front end of the trailing edge section 1d is provided with a support plate 1d1, and the middle part of the support plate 1d1 is provided with a spanwise chute 1d1a.

[0030] The honeycomb support structure is an integrated overall structure, which is made of polyamide or polye...

Embodiment 2

[0033] Among them, the preparation method of the flexible skin can be as follows: the curing agent composed of silicone rubber Sylgard184, vinyl silicone oil and platinum catalyst is weighed according to the mass ratio of 10:1, and 0-10% diluent is added, mechanically stirred and ultrasonically The method of dispersion is mixed to obtain the resin; the configured resin is poured into the mold to make it soak into the unidirectional elastic nylon fabric; pressure is applied to squeeze out the excess resin. After adding the resin, let it stand at room temperature, then put it into an oven, and complete the curing under the condition of 60-100°C. Curing is considered complete when the surface is not tacky. After taking out the mold, let it cool down to room temperature naturally, take out the material from the mold, cut it properly, and get a flexible skin. Among them, when infiltrating the unidirectional elastic nylon fabric, the method of stacking layer by layer is adopted. Af...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com