A tile lifting rack

A lifting frame and tile technology, applied in the direction of crowbars, lifting devices, etc., can solve the problems of easy arm fatigue, easy loss of water from cement, affecting tile laying, etc., and achieve the effect of reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

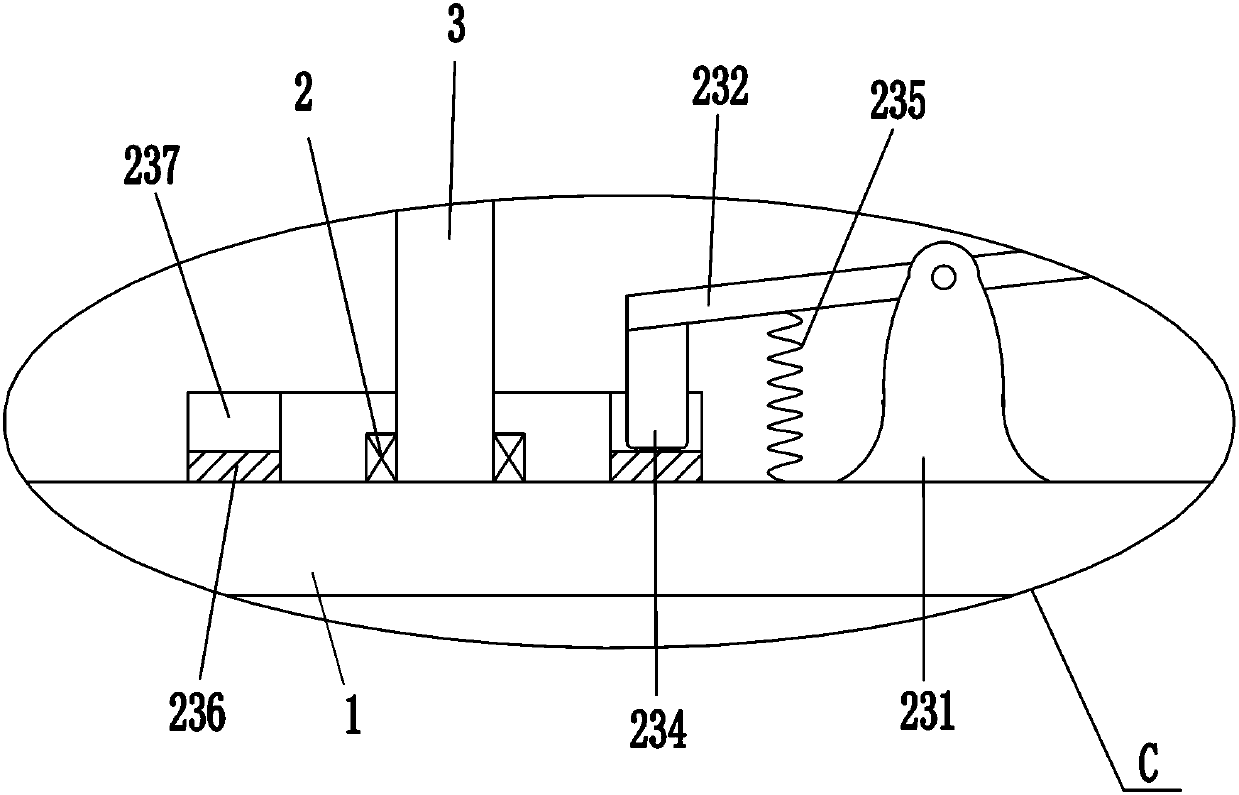

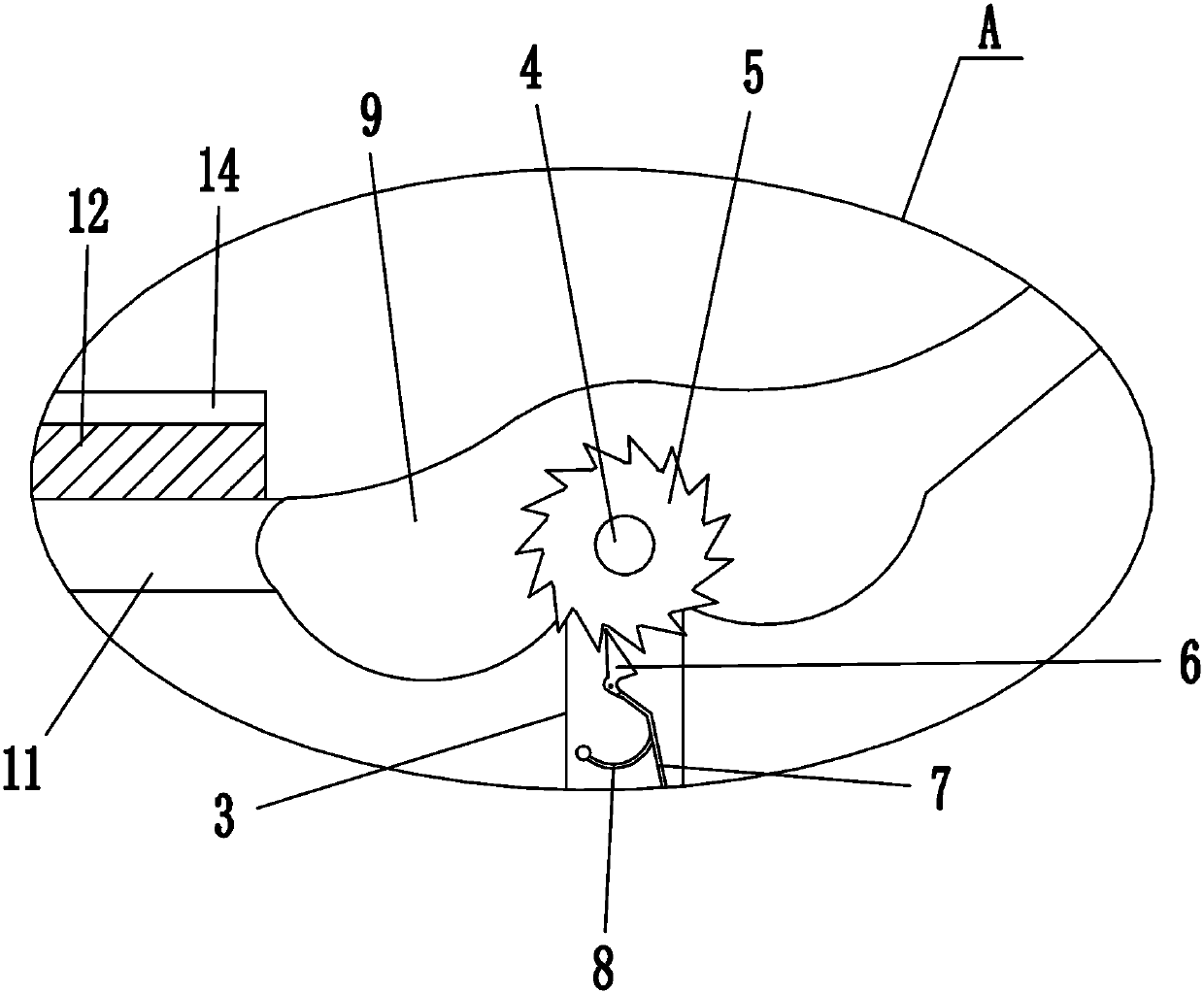

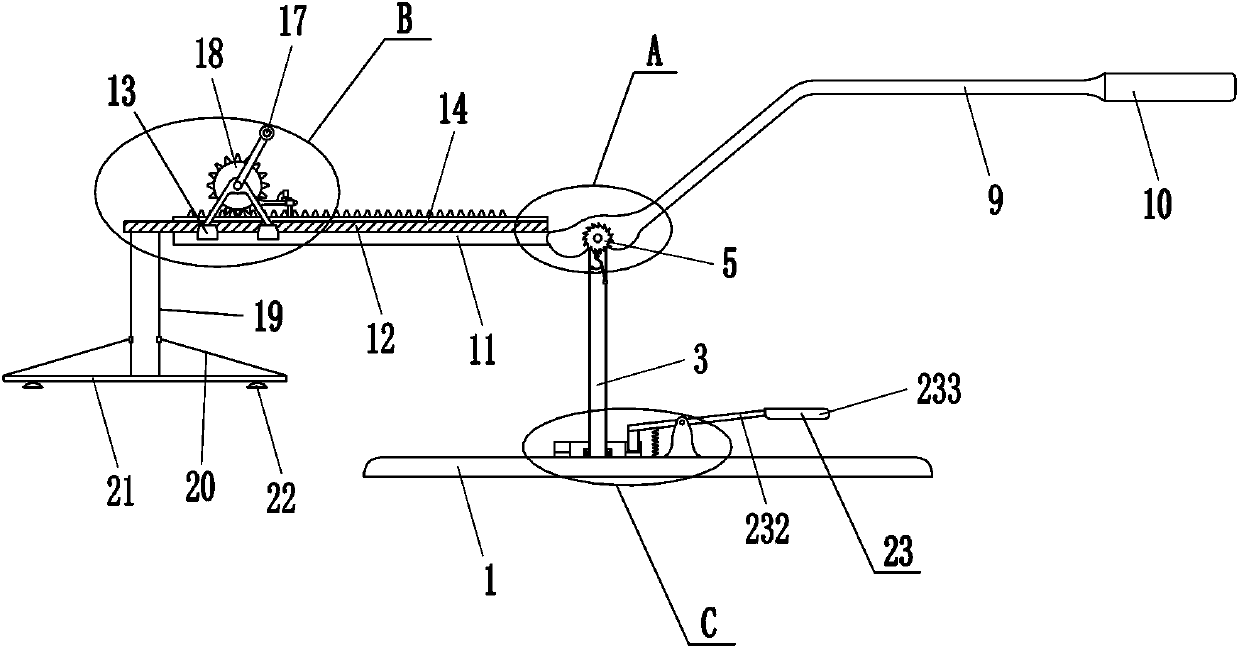

[0018] A tile lifting frame such as Figure 1-4 As shown, it includes a base 1, a bearing seat 2, a pole 3, a rotating shaft 4, a ratchet 5, a pawl 6, a lever 7, a shrapnel 8, a joystick 9, a handle 10, a cross bar 11, a slide rail 12, and a slider 13. Rack 14, bracket 15, rotating rod 16, rocking bar 17, gear 18, first stay cord 19, second stay cord 20, mounting plate 21 and suction cup 22, bearing seat 2 is installed on the left side of base 1 top, A support rod 3 is installed inside the bearing housing 2, a rotating shaft 4 is installed on the upper part of the supporting rod 3, and a ratchet 5 is installed on the front part of the rotating shaft 4. meshing, the bottom end of the ratchet 6 is connected with a driving lever 7, and a shrapnel 8 is connected between the left side of the driving lever 7 and the upper left side of the front side of the support rod 3, a joystick 9 is installed at the rear end of the rotating shaft 4, and a handle is installed at the right end of ...

Embodiment 2

[0020] A tile lifting frame such as Figure 1-4 As shown, it includes a base 1, a bearing seat 2, a pole 3, a rotating shaft 4, a ratchet 5, a pawl 6, a lever 7, a shrapnel 8, a joystick 9, a handle 10, a cross bar 11, a slide rail 12, and a slider 13. Rack 14, bracket 15, rotating rod 16, rocking bar 17, gear 18, first stay cord 19, second stay cord 20, mounting plate 21 and suction cup 22, bearing seat 2 is installed on the left side of base 1 top, A support rod 3 is installed inside the bearing housing 2, a rotating shaft 4 is installed on the upper part of the supporting rod 3, and a ratchet 5 is installed on the front part of the rotating shaft 4. meshing, the bottom end of the ratchet 6 is connected with a driving lever 7, and a shrapnel 8 is connected between the left side of the driving lever 7 and the upper left side of the front side of the support rod 3, a joystick 9 is installed at the rear end of the rotating shaft 4, and a handle is installed at the right end of ...

Embodiment 3

[0023] A tile lifting frame such as Figure 1-4As shown, it includes a base 1, a bearing seat 2, a pole 3, a rotating shaft 4, a ratchet 5, a pawl 6, a lever 7, a shrapnel 8, a joystick 9, a handle 10, a cross bar 11, a slide rail 12, and a slider 13. Rack 14, bracket 15, rotating rod 16, rocking bar 17, gear 18, first stay cord 19, second stay cord 20, mounting plate 21 and suction cup 22, bearing seat 2 is installed on the left side of base 1 top, A support rod 3 is installed inside the bearing housing 2, a rotating shaft 4 is installed on the upper part of the supporting rod 3, and a ratchet 5 is installed on the front part of the rotating shaft 4. meshing, the bottom end of the ratchet 6 is connected with a driving lever 7, and a shrapnel 8 is connected between the left side of the driving lever 7 and the upper left side of the front side of the support rod 3, a joystick 9 is installed at the rear end of the rotating shaft 4, and a handle is installed at the right end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com