Pipes coupling equipment

A technology of pipeline joints and crimping sleeves, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc. The effect of taking off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

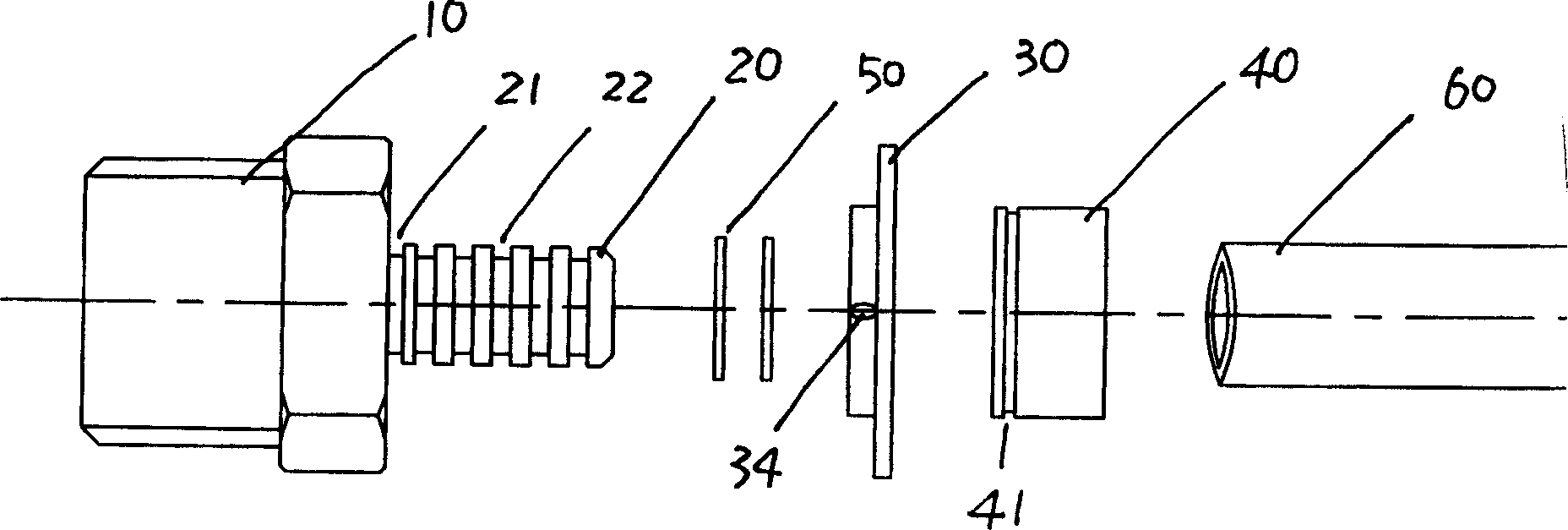

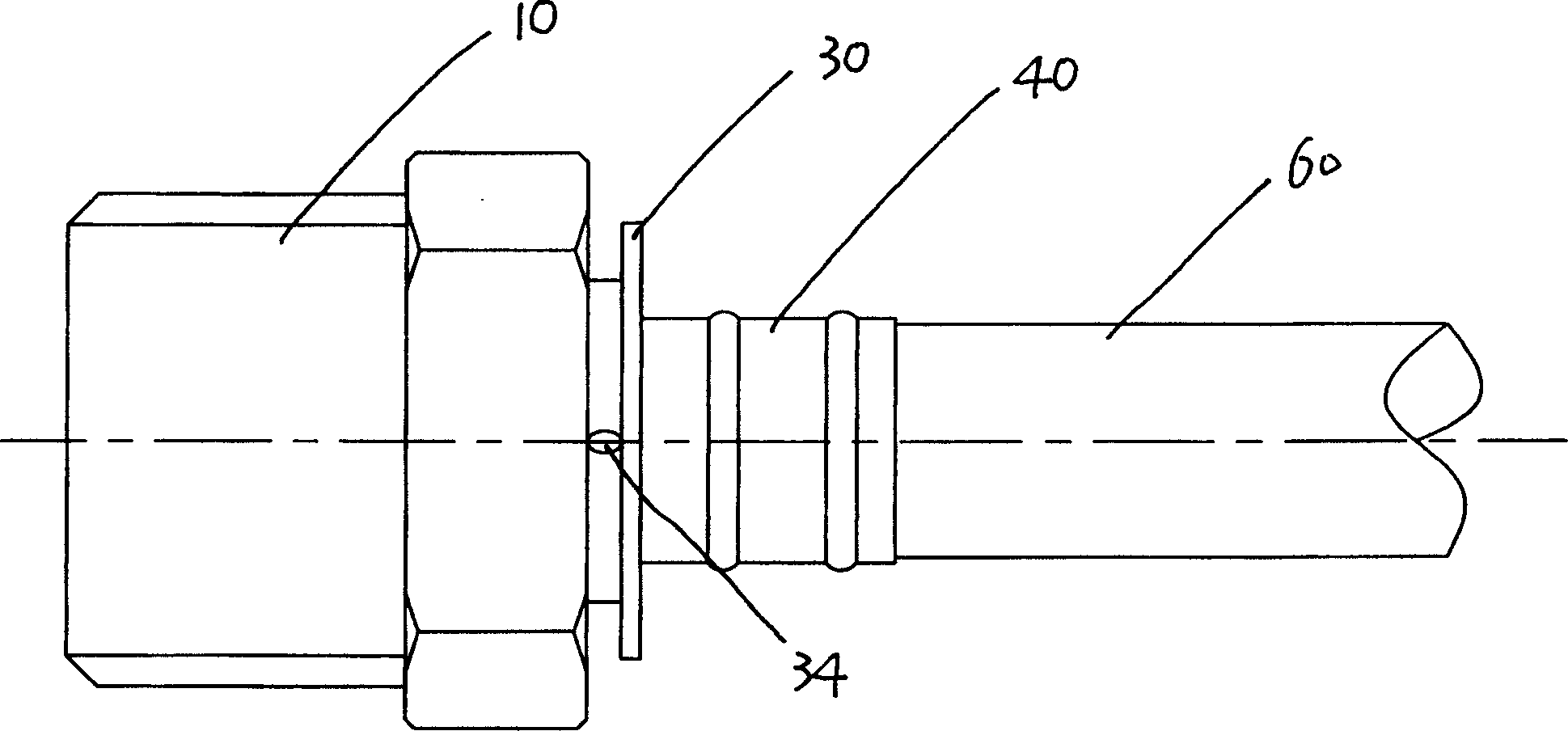

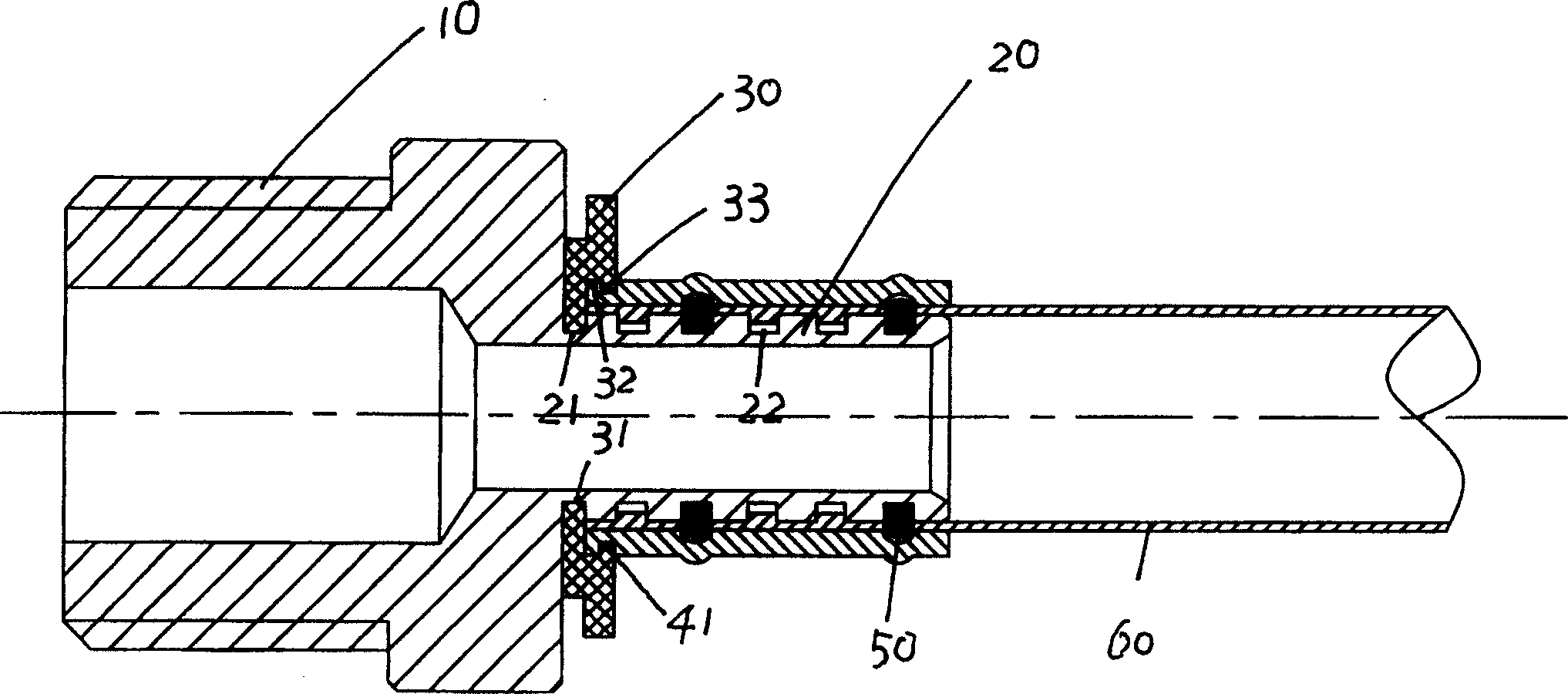

[0014] Example: such as figure 1 , figure 2 , image 3 As shown, a pipeline joint device includes a joint main body 10, a sleeve body 20, a PE fixing sleeve 30, a crimping sleeve 40, and a high elastic sealing ring 50. The joint main body 10 can be manufactured according to user requirements. Various sizes and shapes are available for users to choose.

[0015] The bottom of the fitting body 20 is provided with an engaging groove 21, and a PE fixing sleeve 30 is fixed on the engaging groove 21. The inner hole of the PE fixing sleeve 30 is stepped, and the small hole 31 at the rear is closely fitted and fixed with the engaging groove 21. The large hole 32 at the front is used for the crimping sleeve 40 to be inserted. A ring of flanges 33 is provided at the front of the large hole 32, and a ring of grooves 41 is provided on the outer edge of the rear end of the crimping sleeve 40. The crimping sleeve 40 is inserted into the PE fixing sleeve When the large hole 32 of 30 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com