Electrified ice melting topological system and ice melting method thereof

An ice-melting method and ice-melting technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of high line structure requirements, inability to be well promoted and used, and high system consumption, so as to improve the ice resistance level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

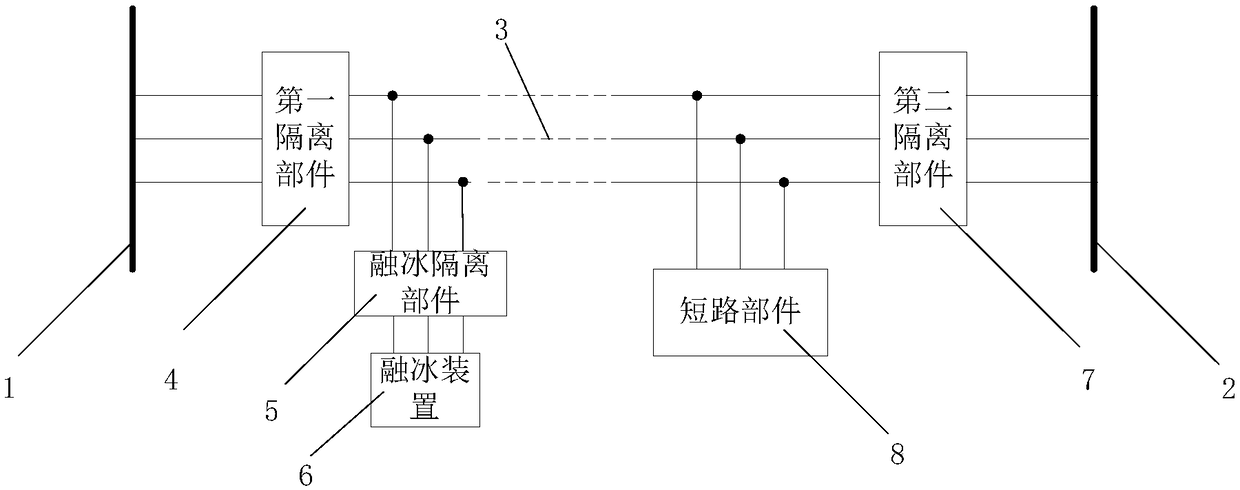

[0022] like figure 1 As shown, this embodiment provides a live ice-melting topological system, including an ice-melting isolation part 5 arranged in parallel on the power transmission line 3, an ice-melting device 6 connected in series outside the ice-melting isolation part 5, and connected in parallel to the power transmission line 3. The short-circuit component 8 on the line 3 is used for short-circuiting the ice-melting current on the transmission line 3 .

[0023] In practical applications, the short-circuit component 8 can be designed as a band-resistance wave blocking circuit, which can be cut off at 50 Hz and turned on at other frequencies. Specifically, the short-circuit component 8 is used to short-circuit the A, B, and C three-phase lines of the transmission line 3, and is in a short-circuit state when it is turned on. After short-circuiting, any phase line in the A, B, and C three-phase lines can be To melt ice, at this time, the short-circuit component 8 is in an ...

Embodiment 2

[0031] This embodiment provides an ice-melting method applied to the charged ice-melting topological system in the above-mentioned embodiment 1, including the following steps:

[0032] S1: Connect the ice-melting isolation part 5 to the power transmission line 3 in parallel, and connect the ice-melting device 6 in series to the outside of the ice-melting isolation part 5, and connect the short-circuit part for short-circuiting the power transmission line 3 in series on the power transmission line 3 8;

[0033] S2: Detect the icing situation on the transmission line 3, when the icing value on the transmission line 3 is greater than or equal to the icing warning value, turn on the ice-melting isolation part 5 and the short-circuit part 8, and the ice-melting device 6 generates ice-melting voltage and form ice-melting channels.

[0034] In this embodiment, steps are also included:

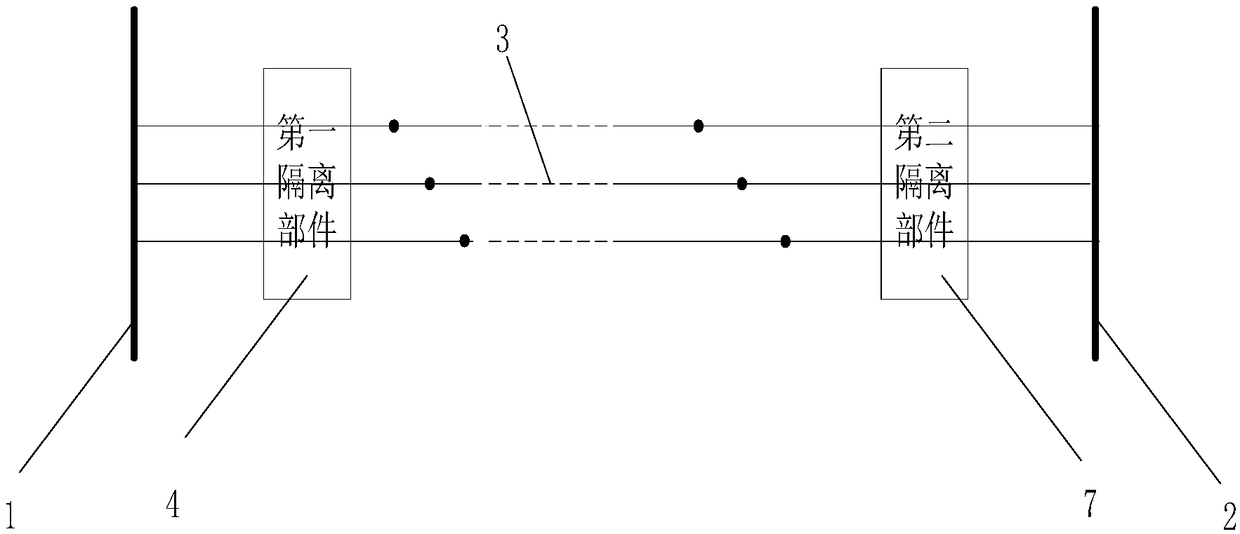

[0035] S3: When the ice coating value on the power transmission line 3 is less than the ice coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com