Hot gas anti-icing structure of forward-sloped engine support plate

An engine and hot gas technology, which is applied to machines/engines, mechanical equipment, jet propulsion devices, etc., can solve the problems of low thermal conductivity, increased demand for compressor anti-icing hot gas, restricting engine performance, etc., to reduce the amount of bleed air and Bleed air temperature, improved anti-icing effect, reduced engine weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

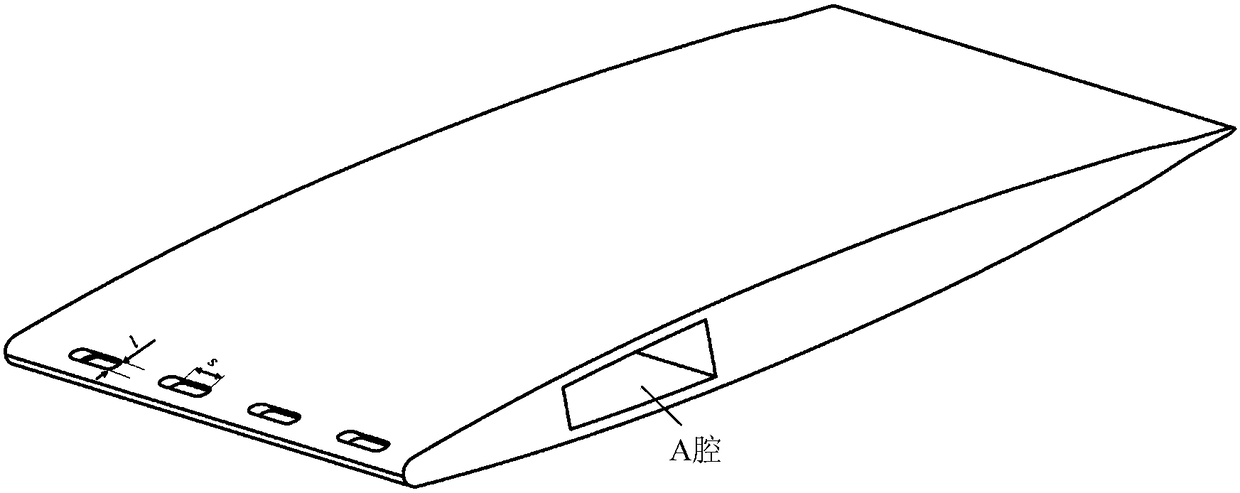

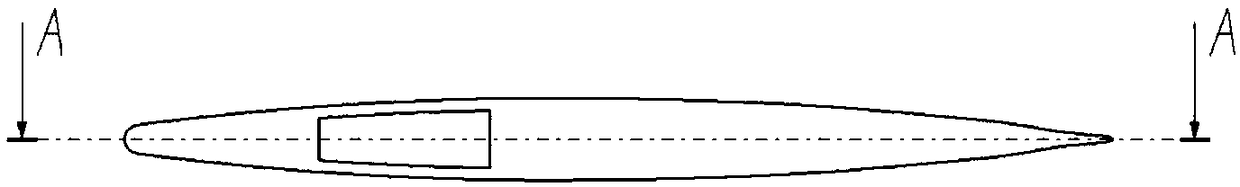

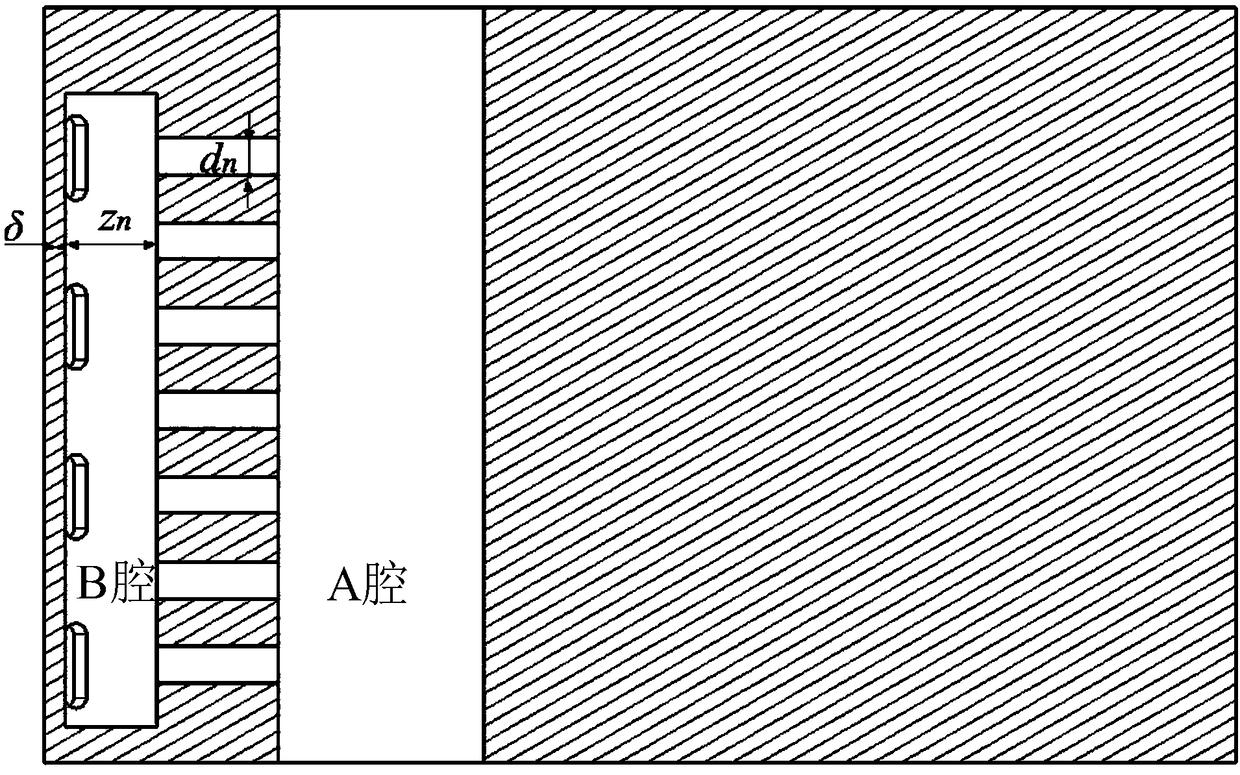

[0029] The opening angle of the gas film seam of the support plate used in the test points to the direction of the front edge, its structural parameters are shown in Table 1, and its shape structure is as follows figure 1 and image 3 shown.

[0030] Table 1 Basic structural parameters of composite struts

[0031] Leading edge thickness δ

Gas film slit width l

Impact hole distance s

Gas film slit length b

Impact distance Zn

Impact aperture d h

[0032] The slit angle of the air film seam has a significant impact on the anti-icing characteristics of the support plate, including the air film heating characteristics of the outer wall surface, the water droplet impact characteristics of the outer wall surface, and the impact heat transfer characteristics of the inner leading edge wall surface.

[0033] In order to preliminarily explore the mechanism of the influence of hot air film on the anti-icing characteristics of struts, the Euler me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com