Enzyme pickled vegetables and preparation method thereof

A kimchi and enzyme technology, applied in the field of enzyme kimchi and its preparation, can solve the problems of air pollution, improper preservation, high nitrite content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

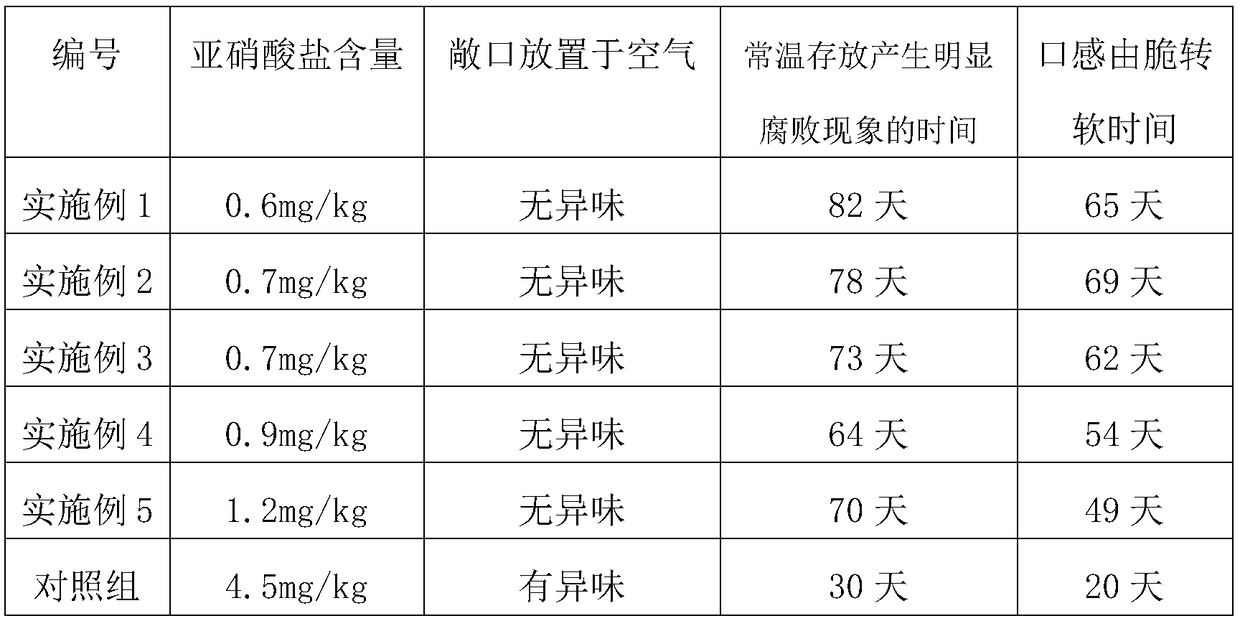

Examples

Example Embodiment

[0025] Example 1:

[0026] Step (1): Add 5 kg of apple, 5 kg of onion, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir well, keep at 25°C for 10 hours, raise the temperature to 36°C for 5 hours, then lower the temperature to 0°C for 5 hours, then Raise the temperature to 31℃ for 20 hours, then cool to 20℃;

[0027] Step (2): Cut 100 kilograms of cabbage and put the whole leaf into a container containing the mixture of step (1) temperature-regulated and fermented. The mixture should be covered with vegetables, and the mixture should be evenly mixed and sealed, and then set aside at 30°C 10 days;

[0028] Step (3): cooling the mixture obtained in step (2) to 0°C, bagging and sealing to obtain the product enzyme kimchi;

[0029] Step (4): Store the prod...

Example Embodiment

[0030] Example 2:

[0031] Step (1): Add 5 kg of apple, 5 kg of onion, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir well, keep at 25°C for 10 hours, raise the temperature to 36°C for 5 hours, then lower the temperature to 0°C for 5 hours, then Raise the temperature to 31℃ for 20 hours, then cool to 20℃;

[0032] Step (2): Cut 100 kilograms of white radishes into one-centimeter thick slices, and put them into a container containing the mixture after temperature adjustment and fermentation in step (1). The mixture should be covered with vegetables. The mixture should be evenly mixed and sealed at 30°C. Let stand for 10 days;

[0033] Step (3): cooling the mixture obtained in step (2) to 0°C, bagging and sealing to obtain the product enzyme kimchi; ...

Example Embodiment

[0035] Example 3:

[0036] Step (1): Add 5 kg of apple, 5 kg of onion, 0.5 kg of garlic, 0.5 kg of ginger powder, 0.1 kg of chili powder, 2 kg of salt, 1 kg of sugar, 0.1 kg of pepper powder, 0.2 kg of lactic acid bacteria, 0.2 kg of yeast, Put 0.2 kg of acetic acid bacteria into a container, add distilled water twice the mass of the above mixture, stir well, keep at 25°C for 10 hours, raise the temperature to 36°C for 5 hours, then lower the temperature to 0°C for 5 hours, then Raise the temperature to 35°C for 5 hours, then cool to 20°C;

[0037] Step (2): Cut 100 kilograms of cucumber into one-centimeter thick slices, and put them into a container containing the mixture after temperature adjustment and fermentation in step (1). The mixture should be covered with vegetables. After evenly mixing, it should be sealed and kept at 30℃. Set for 10 days;

[0038] Step (3): cooling the mixture obtained in step (2) to 0°C, bagging and sealing to obtain the product enzyme kimchi;

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com