Injection system of dish washing machine and control method of injection system and dish washing machine

A technology of spraying system and dishwasher, which is applied to washing machine/washing machine for dishes, parts of washing machine/rinsing washing machine for dishes, cleaning equipment, etc., can solve the problem of weak cleaning ability in corner areas and inability to clean dishwasher cavity The corner areas of the body and the inability to achieve zoned cleaning can achieve the effect of improving user satisfaction, improving user satisfaction, and expanding the scope of jet cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

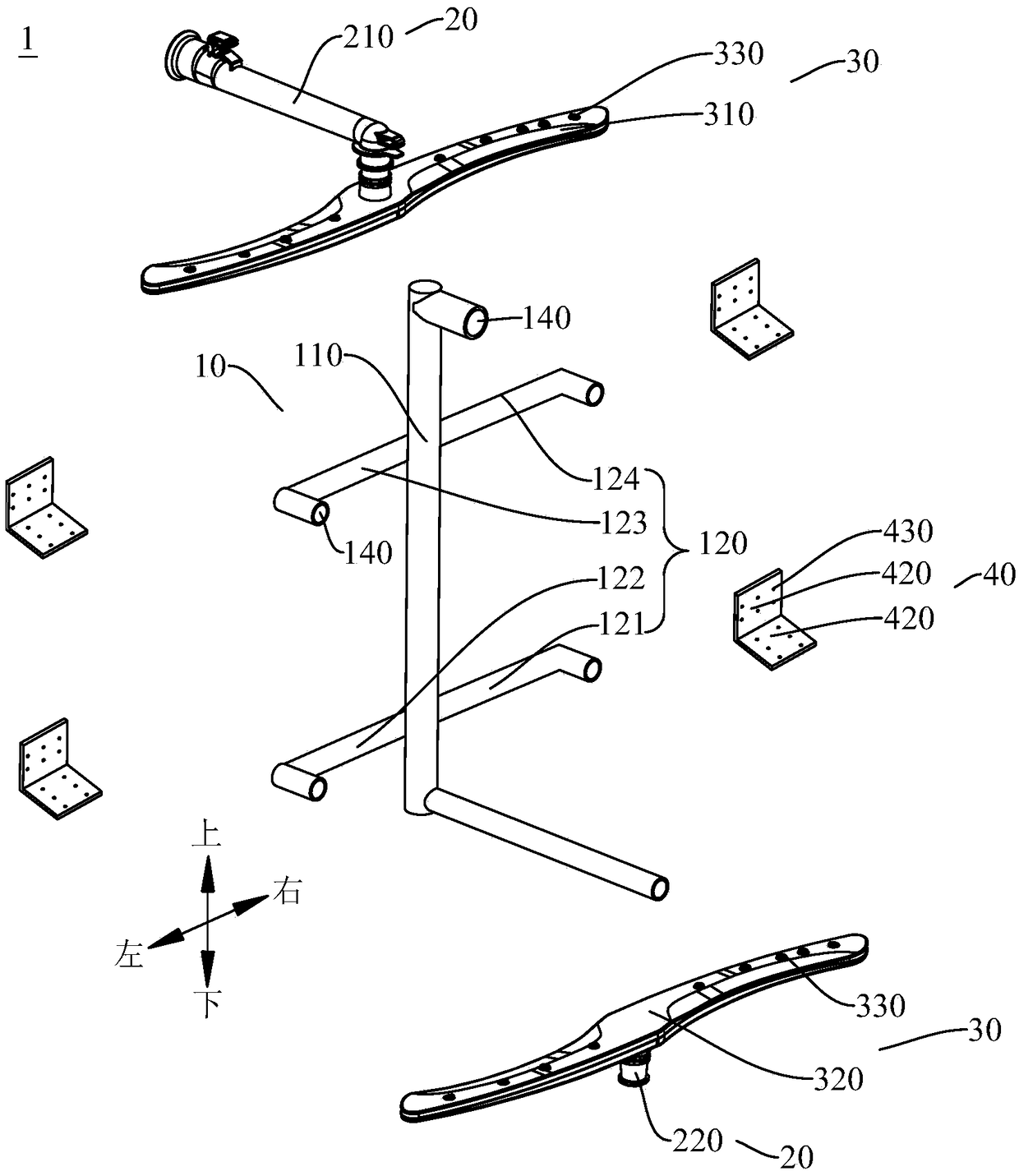

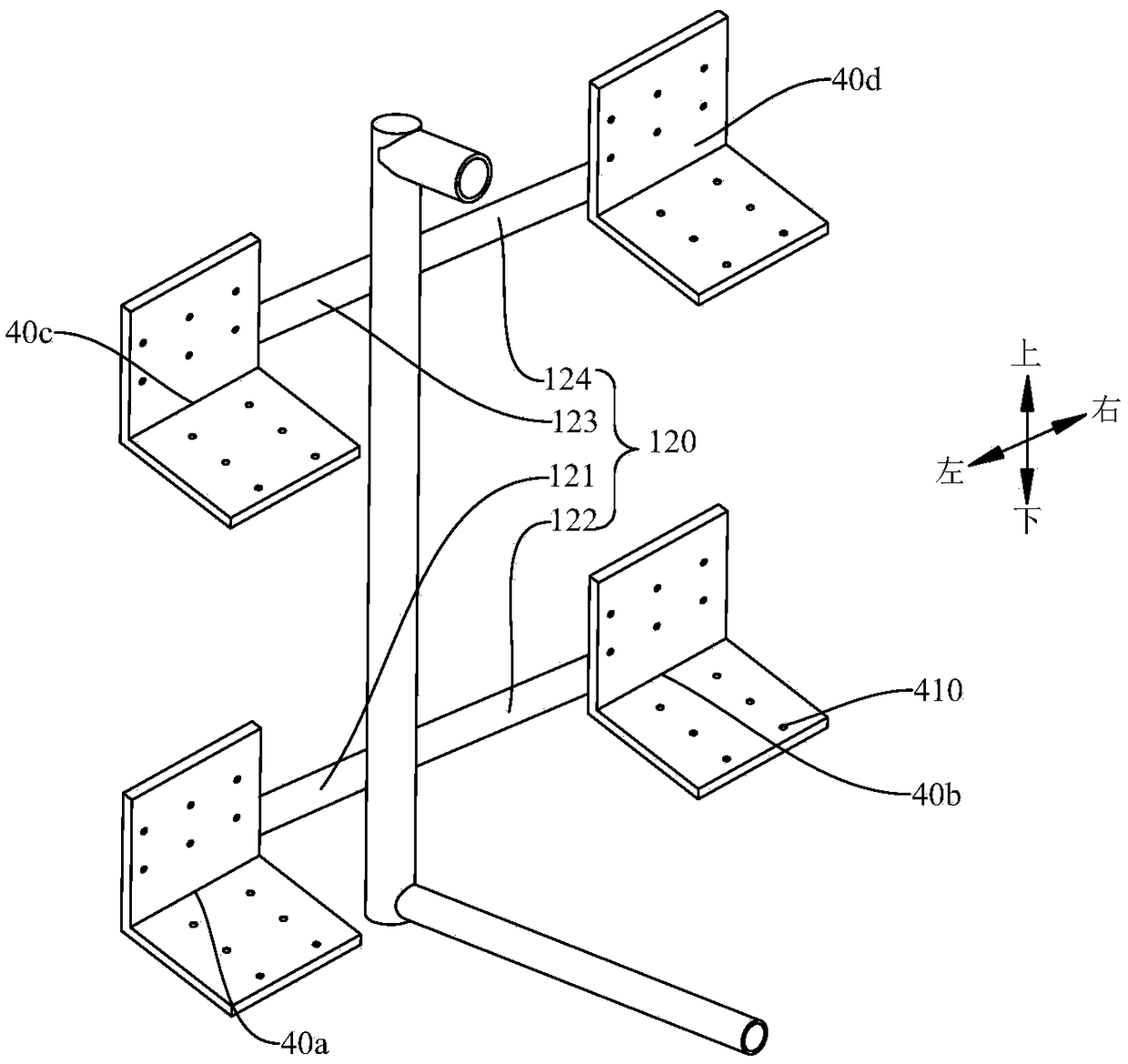

[0107] Refer below Figure 1-Figure 5 A spray system 1 of a dishwasher according to a specific embodiment of the present invention will be described.

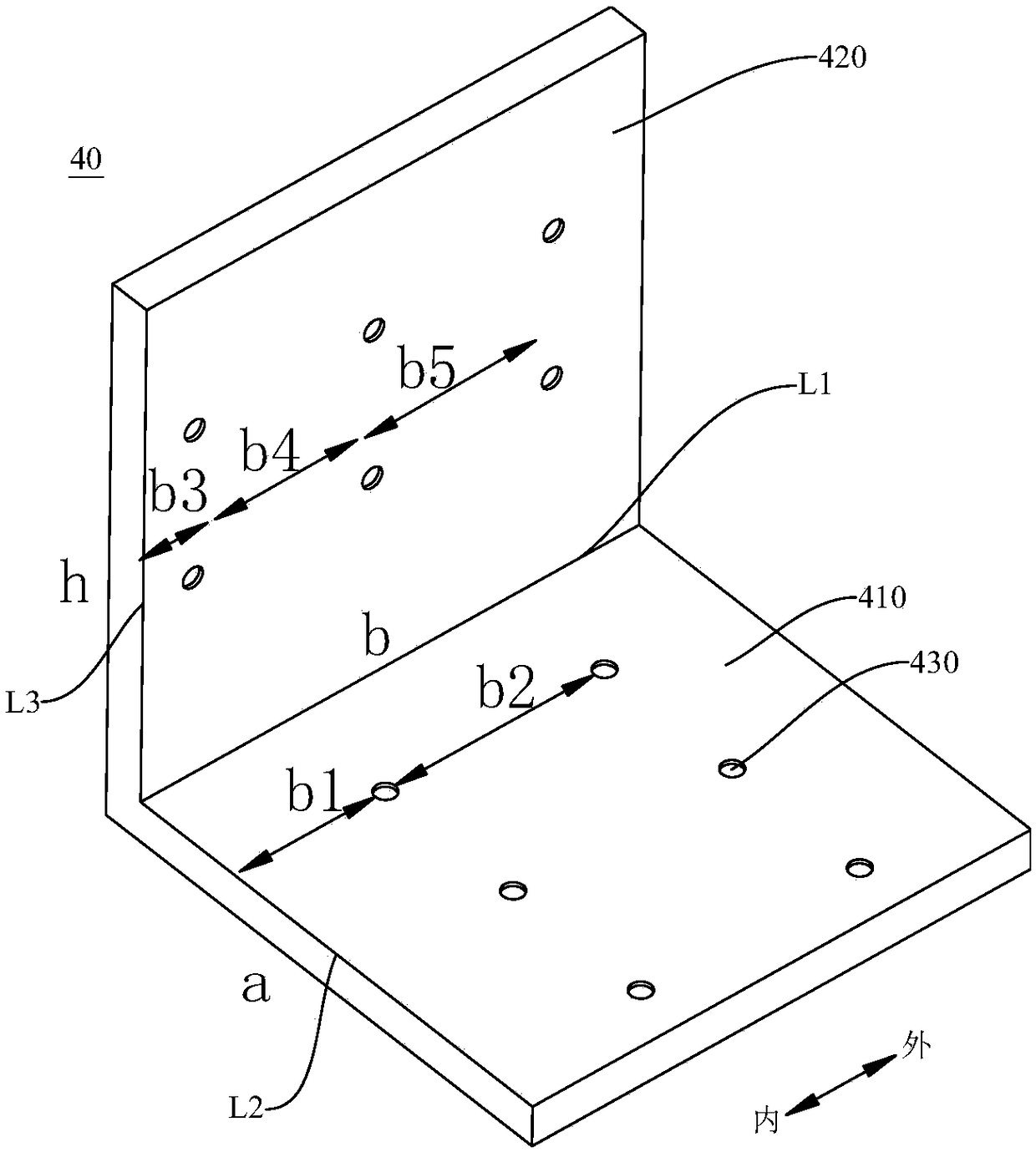

[0108] As shown in the figure, the spray system 1 of this embodiment includes a water supply assembly 10, an upper spray arm seat 210, a lower spray arm seat 220, an upper spray arm 310, a lower spray arm 320, an auxiliary spray member 40 and a control valve. The water supply assembly 10 With a water inlet 130 and six water outlets 140 , the water supply assembly 10 is used to guide the water flow from the water inlet 130 to the six water outlets 140 . The water supply assembly 10 includes a riser pipe 110, the riser pipe 110 is arranged vertically, the top and the bottom of the riser pipe 110 are respectively connected with an upper spray arm seat 210 and a lower spray arm seat 220, and the upper spray arm 310 and the lower spray arm 320 are respectively pivotable. Ground is connected on the upper spray arm seat 210 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com