Condenser for organic waste gas circulation purification device

A technology for recycling and purifying organic waste gas, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as unqualified gas, unreasonable design, and inadequate oil pollution treatment, and achieve cost savings and eliminate harmful odors gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

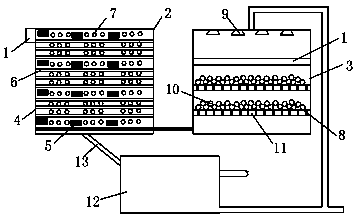

[0013] Combine below figure 1 Specific description embodiment:

[0014] The condenser of the organic waste gas circulation purification equipment includes a fan 1, a condensation box 2 and a spray condensation tower 3. The condensation box includes a box body 4, and the inside of the box body is provided with a cooling water pipeline and a steel wire filter net box 5. The cooling water pipeline includes a horizontal cooling water pipeline 6 and a vertical cooling water pipeline 7. The horizontal cooling water pipeline and the vertical cooling water pipeline are arranged alternately. The steel wire filter net box is made of stainless steel wire layer by layer, and the steel wire filter mesh A steel wire filter screen box is placed in every three rows of cooling water pipes in the box; the spray condensing tower includes a packing device 8, a spray device 9, a water circulation device, and the spray device is located at the top of the spray condensing tower. Including distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com