Longitudinal shearing processing technology of soft cold-rolled sheet

A cold-rolled sheet and processing technology, applied in metal processing equipment, shearing machine equipment, shearing devices, etc., can solve the problems of poor positioning accuracy of the guide device, inability to adjust unilaterally, inaccurate dimensions, etc., and achieve guaranteed accuracy. , The effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

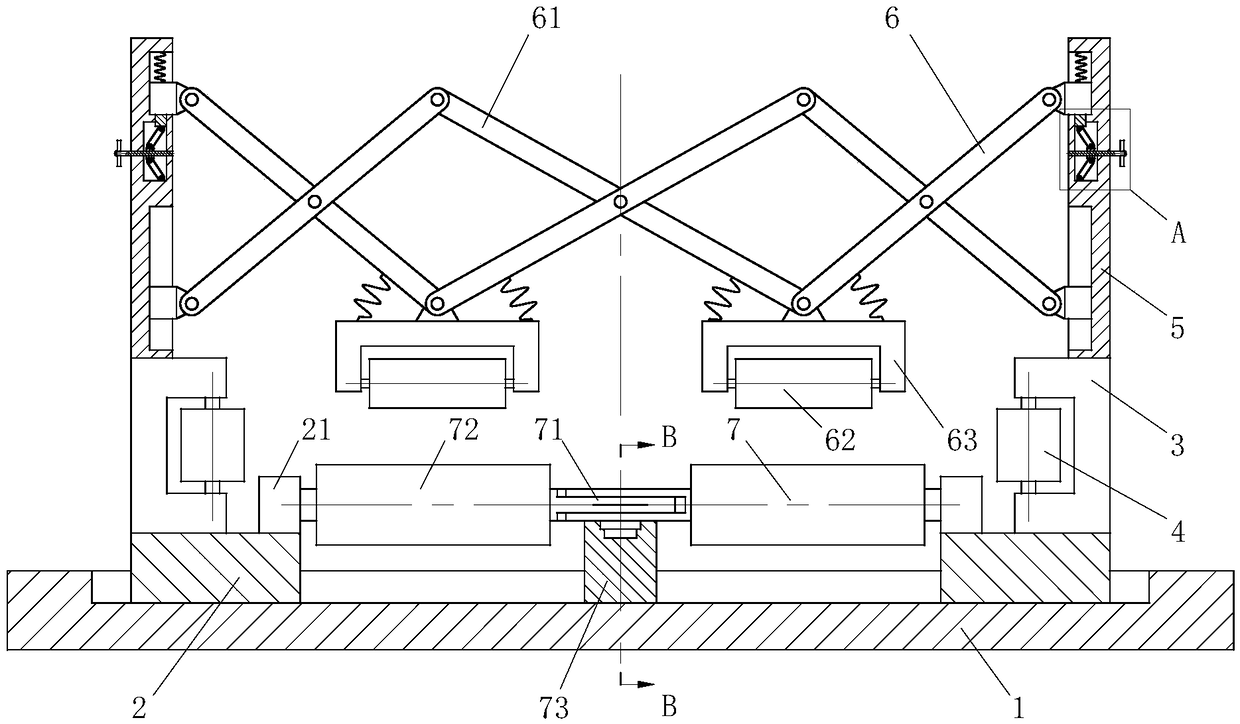

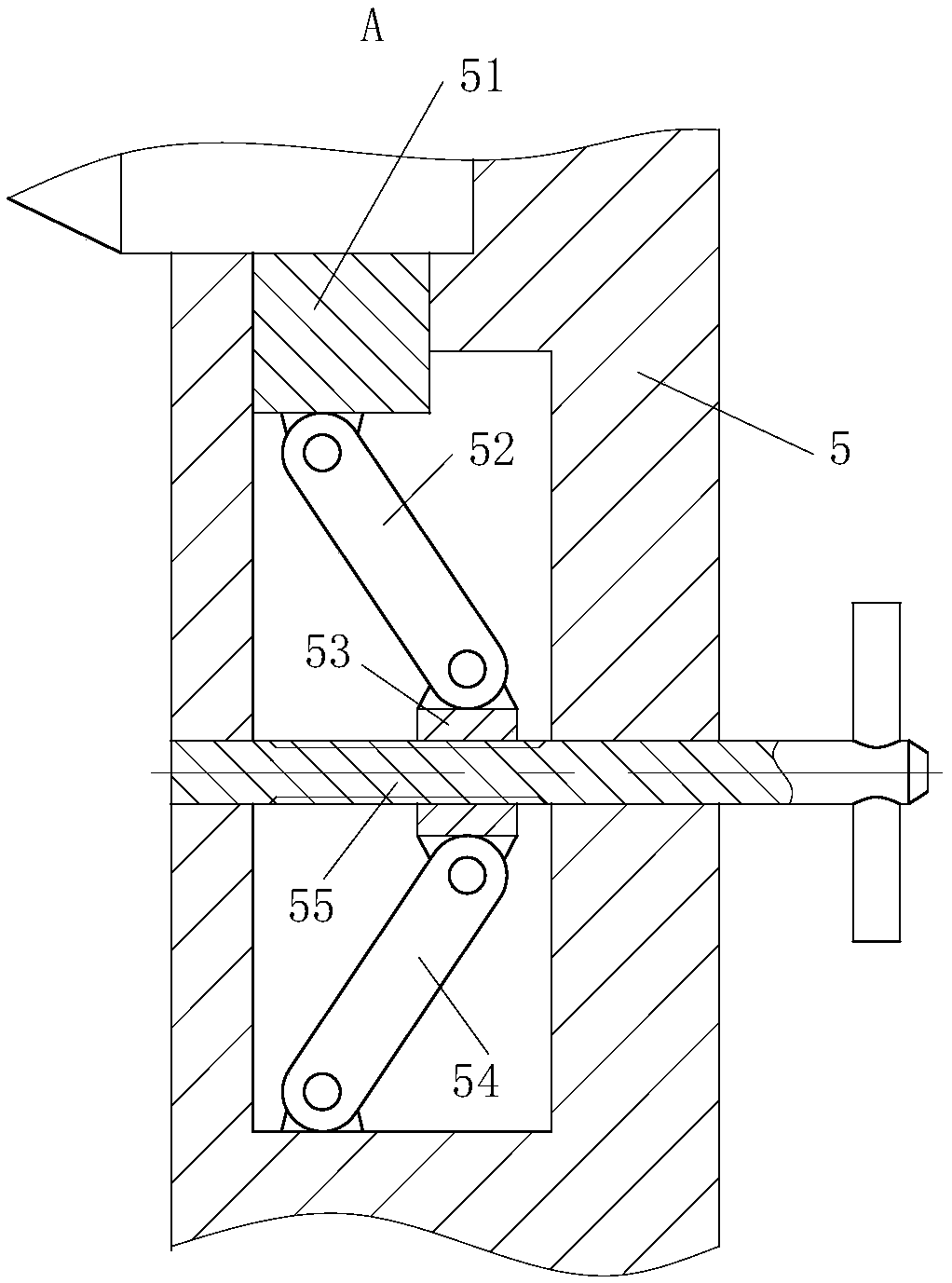

[0027]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

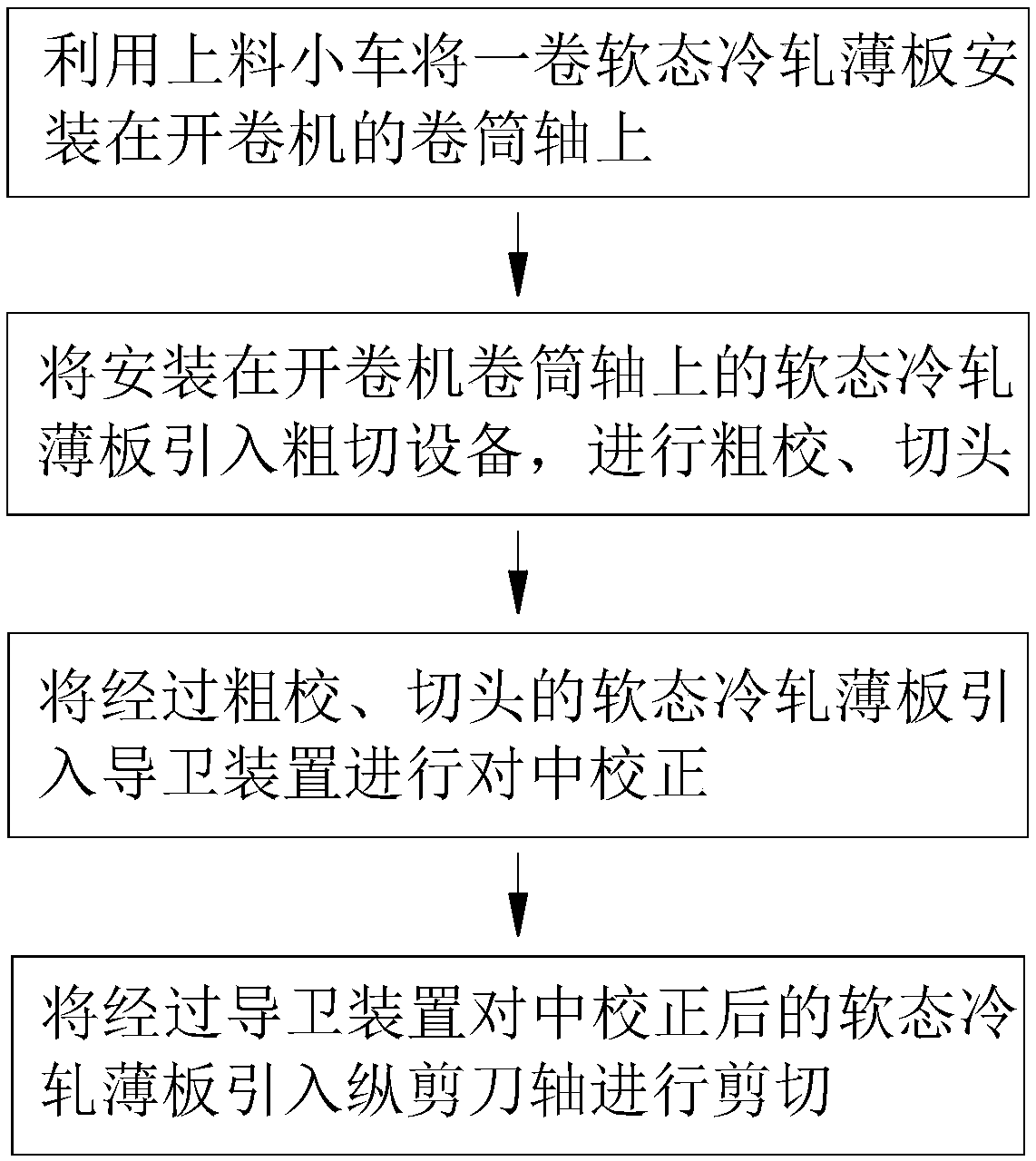

[0028] Such as Figure 1 to Figure 4 Shown, a kind of slitting processing technology of soft cold-rolled sheet of the present invention, this technology comprises the steps:

[0029] Step 1: Install a coil of soft cold-rolled sheet on the drum shaft of the uncoiler by using the feeding trolley;

[0030] Step 2: Introduce the soft cold-rolled sheet installed on the reel shaft of the uncoiler into the rough cutting equipment in step 1 for rough correction and head cutting;

[0031] Step 3: Introduce the soft-state cold-rolled sheet that has undergone rough correction and trimming in step 2 into the guide device for centering correction;

[0032] Step 4: Introduce the soft cold-rolled sheet that has been centered and corrected by the guide device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com