Knitted denim fabric

A technology for knitting denim and fabrics, which is applied in fabrics, textiles, textiles and papermaking, etc., to achieve the effects of good hand feeling, excellent air permeability and sufficient elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

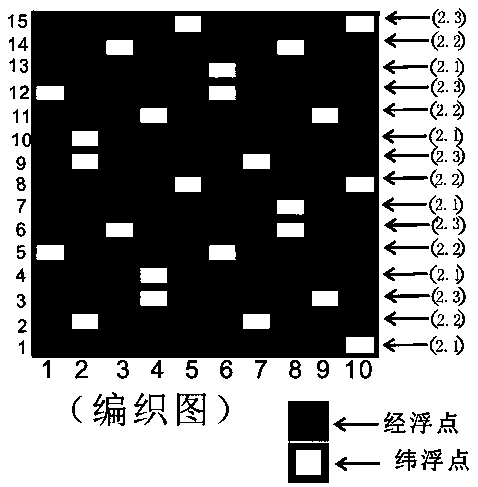

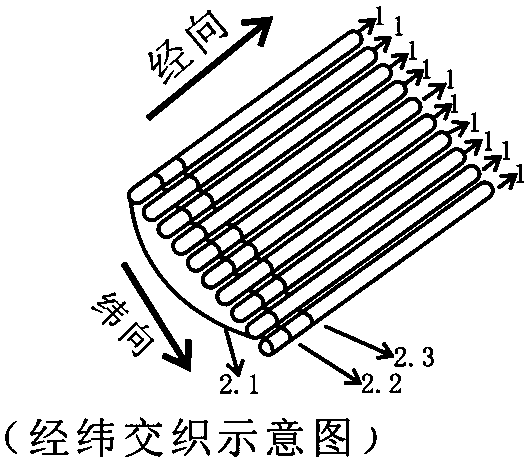

[0020] Example 1: A knitted denim fabric made of warp yarn 1 and weft yarn 2 interwoven with each other by a knitting machine. The warp yarn 1 is a core-spun elastic yarn with a count of 10, and the weft yarn 2 includes: weft yarn 1 2.1, weft two 2.2 and weft three 2.3, the weft one 2.1 is non-stretch yarn or low stretch yarn, the count is 10, weft two 2.2 and weft three 2.3 are core-spun elastic yarn two, and are more than weft yarn 2.1 The elasticity is large, and the number is 10.

[0021] The core-spun elastic yarn-the outer fiber is dyed fiber, the inner core yarn is mono-spandex yarn or double-spandex yarn with a denier of 20D, the inner core yarn is 20D micro-elastic filament, and the inner core yarn is spandex. Double-core or triple-core yarn formed by silk and micro-elastic filament.

[0022] The core yarn in the second core-spun elastic yarn is mono-spandex yarn or double-spandex yarn with a denier of 20D, and the inner core yarn is a double-core or triple-core yarn form...

Embodiment 2

[0028] Embodiment 2: A knitted denim fabric, which is formed by interweaving warp yarn 1 and weft yarn 2 with a knitting machine. The warp yarn 1 is a core-spun elastic yarn with a count of 40. The weft yarn 2 includes: weft yarn 1 2.1, weft two 2.2 and weft three 2.3, the weft one 2.1 is non-stretch yarn or low stretch yarn, the count is 40, weft two 2.2 and weft three 2.3 are core-spun elastic yarn two, and are more than weft yarn 2.1 The elasticity is large, and the number is 60.

[0029] The core-spun elastic yarn-the outer fiber is a dyed fiber, the inner core yarn is mono-spandex yarn or double-spandex yarn, the denier is 70D, the inner core yarn is 70D micro-elastic filament, and the inner core yarn is spandex. Double-core or triple-core yarn formed by silk and micro-elastic filament.

[0030] The core yarn inside the second core-spun elastic yarn is mono-spandex yarn or double-spandex yarn with a denier of 70D, and the inner core yarn is a double-core or triple-core yarn f...

Embodiment 3

[0036] Embodiment 3: A knitted denim fabric made of warp yarn 1 and weft yarn 2 interwoven with each other by a knitting machine, characterized in that the warp yarn 1 is a core-spun elastic yarn with a count of 80, and the weft yarn 2 Including: weft yarn 2.1, weft yarn 2 2.2 and weft yarn 3 2.3, the weft yarn 2.1 is non-stretch yarn or low elastic yarn, the count is 80, weft yarn 2 2.2 and weft yarn 3 2.3 are core-spun stretch yarn 2 and are more than The weft yarn 2.1 has large elasticity, and the count is 80.

[0037] The core-spun elastic yarn-the outer fiber is dyed fiber, the inner core yarn is single spandex yarn or double spandex yarn, the denier is 140D, the inner core yarn is 150D micro-elastic filament, and the inner core yarn is spandex. Double-core or triple-core yarn formed by silk and micro-elastic filament.

[0038] The core yarn in the second core-spun elastic yarn is a single spandex yarn or a double spandex yarn with a denier of 140D, and the inner core yarn is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap