Flapping door unit transmission mechanism and flapping door unit

A technology of transmission mechanism and flapping door, which is applied in the direction of power control mechanism, gate/door, wing leaf control mechanism, etc., which can solve the problem that the direct connection scheme of the control motor drive shaft and the flapping door rotating shaft cannot be adopted, and the flapping door unit cannot be guaranteed to be vertical. For problems such as the horizontal base of the gate installation, the limited height of the gate or the internal space of the automatic ticket gate, it can save maintenance time and labor costs, save maintenance time, and save installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

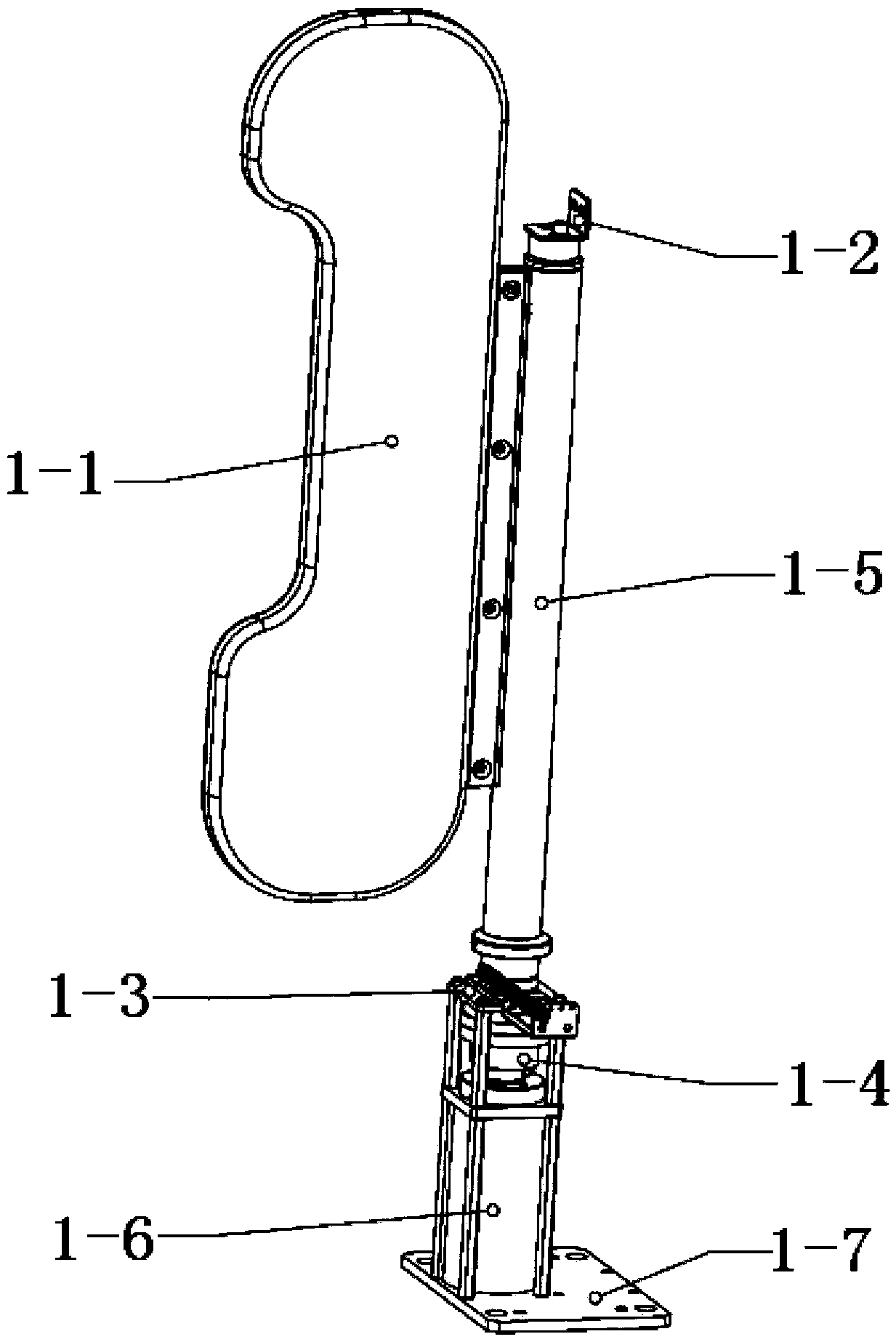

[0086] The driven synchronous pulley 7 is directly nested and installed with the flapping door rotating shaft 10, and the flapping door rotating shaft 10 is inserted into the central hole of the driven synchronous pulley 7, and the two are fixedly connected by splines or other forms, such as Figure 3-1 shown.

Embodiment 2

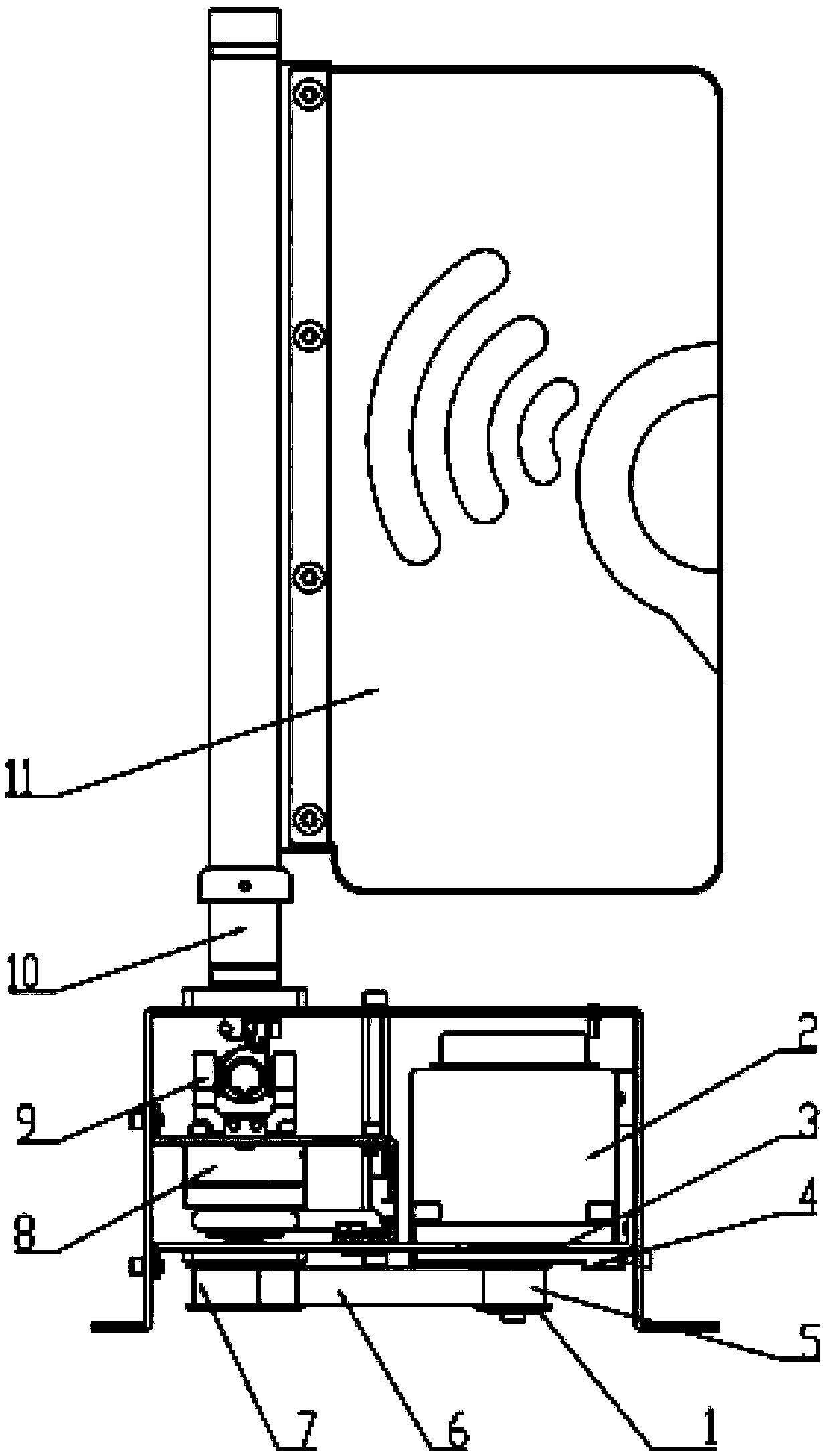

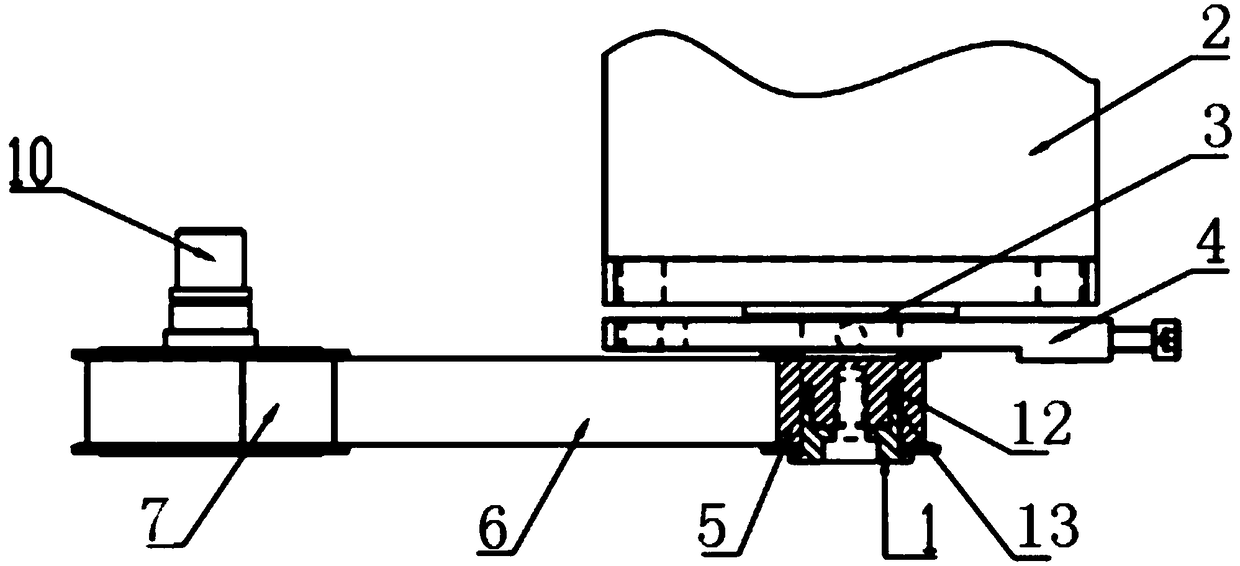

[0088] After installation using the structure of Embodiment 1, since the flapping gate unit depends on the appearance of the whole machine of the gate or automatic ticket gate, the installation position is relatively fixed. There may be cases of different axes, such as Figure 5 As shown, the axis A of the flapping door shaft and the axis B of the driven synchronous pulley's shaft are not on the same straight line, so it is impossible to directly form a transmission linkage. If it is barely connected, it cannot be efficiently transmitted to the flapping door shaft Motion and torque of the shaft from the driven timing pulley.

[0089] Now the preferred scheme is to connect the flapping door rotating shaft and the driven synchronous pulley 7 by the cross shaft universal joint. Rely on the cross shaft universal joint 9 to carry out the transmission linkage between the driven synchronous pulley 7 and the flapping door rotating shaft 10. The cross shaft universal joint is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com