Multifunctional cement mixer

A cement mixer, multi-functional technology, applied in cement mixing device, electromechanical device, casing/cover/support, etc., can solve the problems of unsatisfactory mixing effect of the mixer, uneven cement mixing, insufficient mixing speed, etc. Improve the working environment of workers, improve the mixing efficiency, and the effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

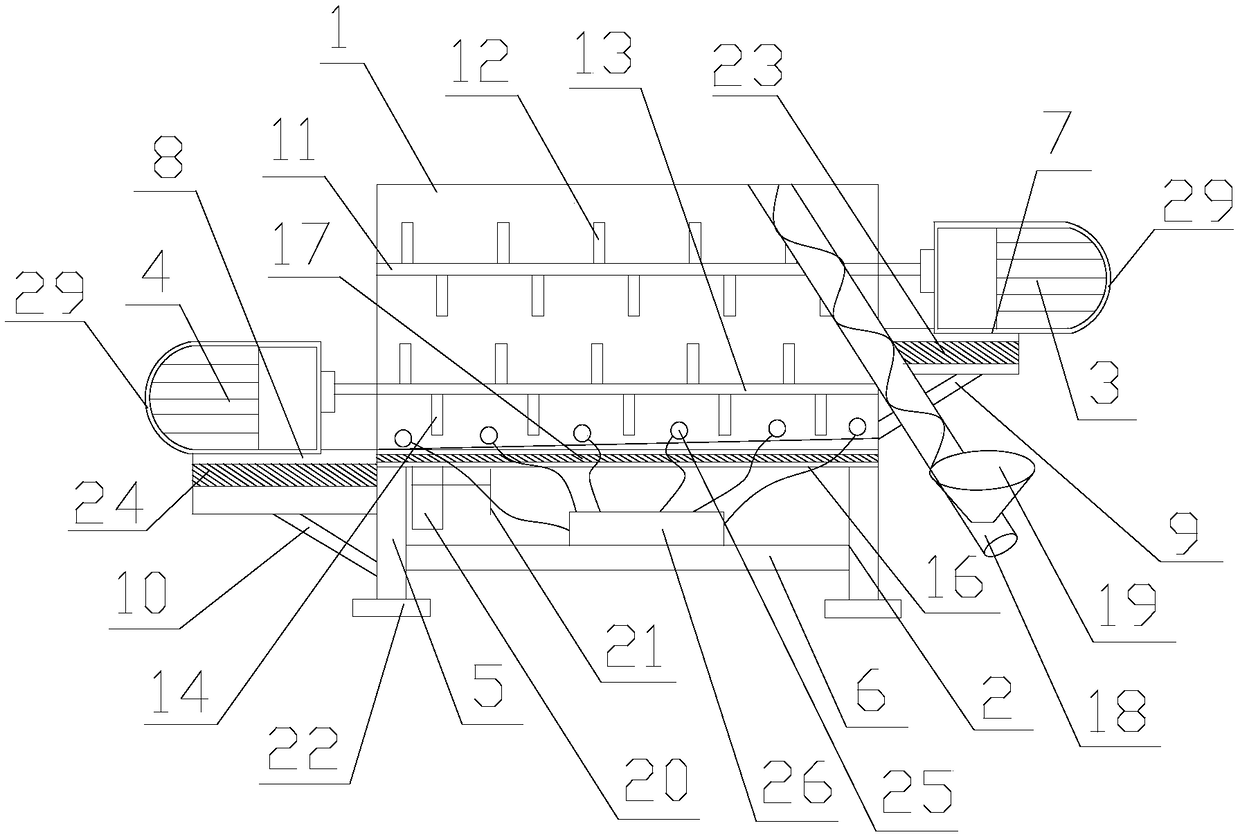

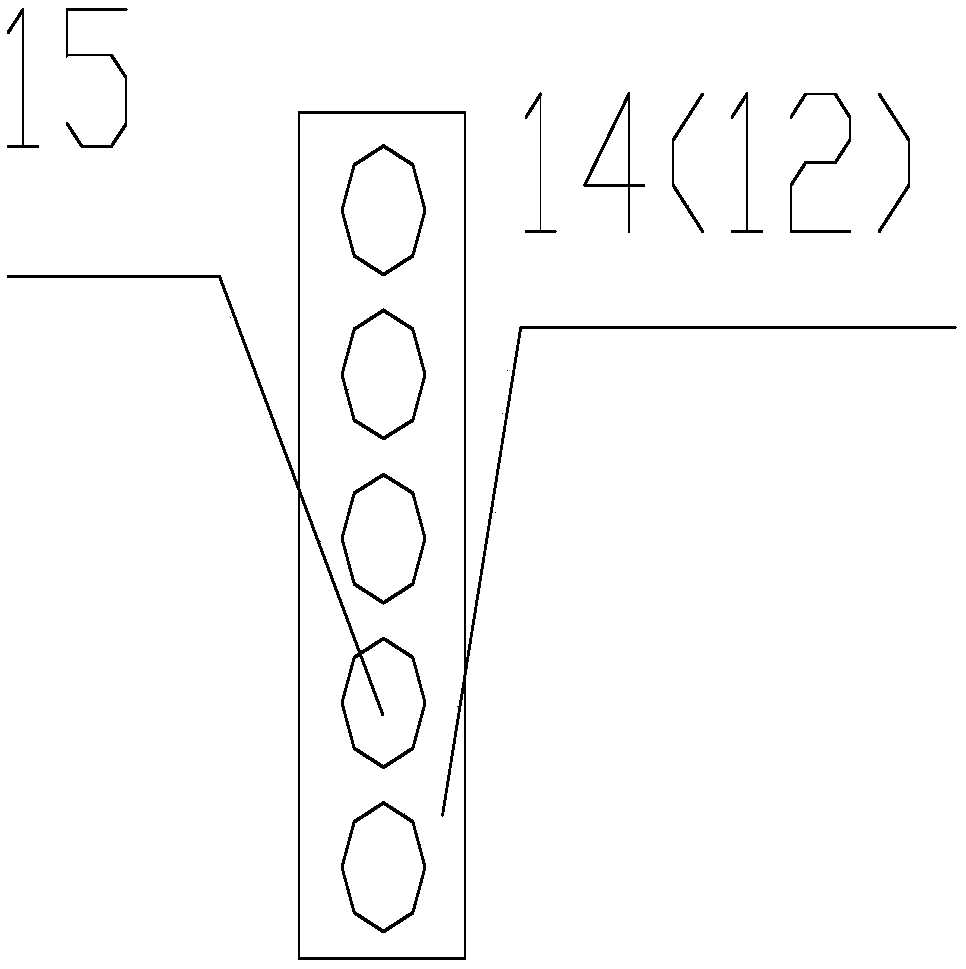

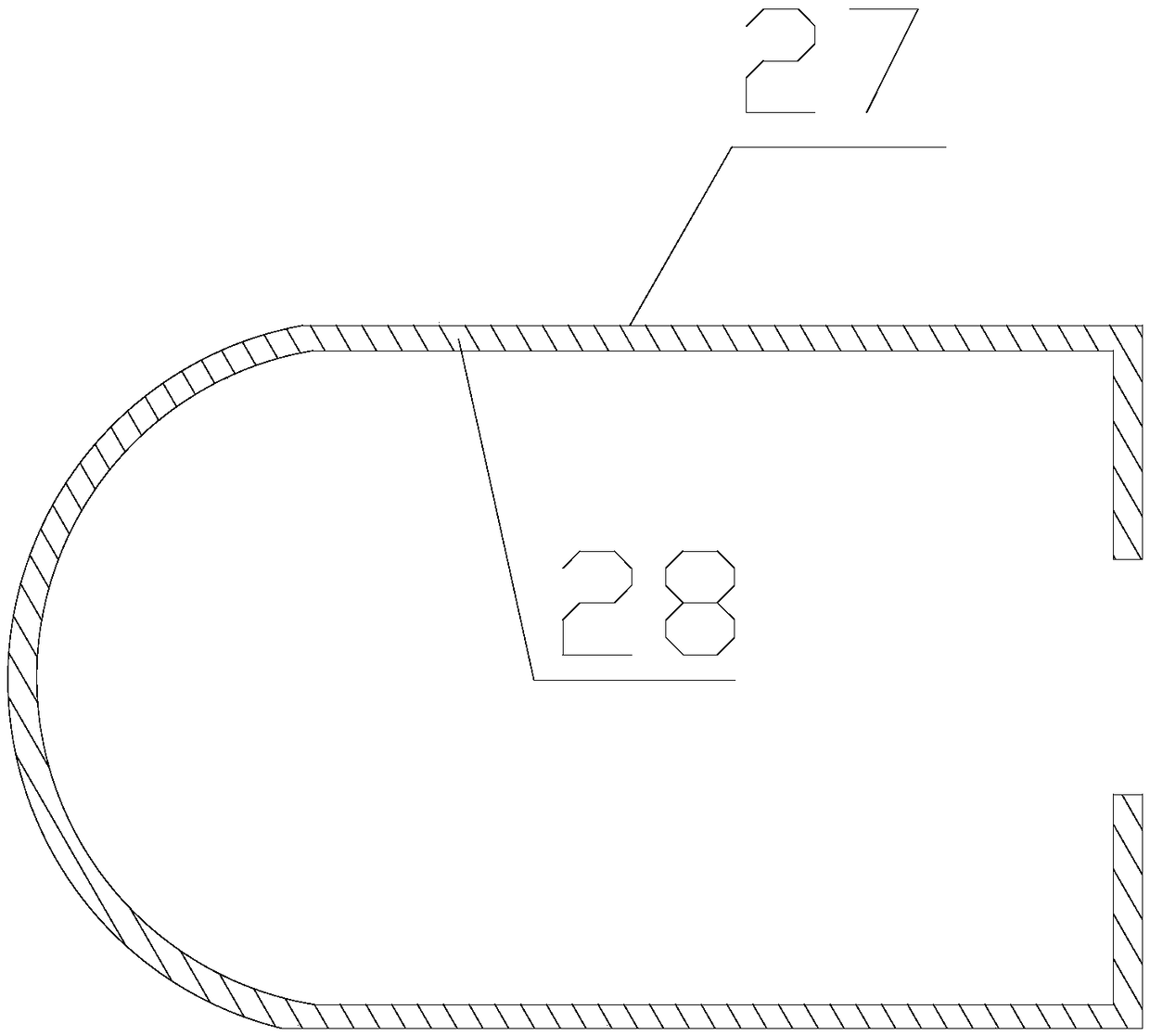

[0023] like Figure 1-3 As shown, the multifunctional cement mixer provided by the present invention has simple structure, scientific and reasonable design, convenient use, high mixing efficiency, uniform mixing, effective protection of the mixing box and driving motor, and more uniform mixing at the bottom of the mixing box. The present invention includes a stirring box 1 with a feed inlet at the top and a discharge opening at the bottom, a support frame device 2 located directly below the stirring box 1 for supporting the stirring box 1, located in the stirring box 1 and from top to bottom The first stirring device and the second stirring device of the lower distribution, the feeding device connected with the feed port, the discharge device connected with the discharge port, and the first drive motor 3 and the second drive motor 4, the stirring box The bottom of the body 1 is an inclined plane and the angle between the horizontal plane is 15°-30°, the bottom of the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com