Secondary buckling part molding angle-ejection device and injection mold

A technology of slanted top and slanted head, which is applied in the field of secondary buckle forming slanted top device and injection mold, which can solve the problems of lengthening the molding cycle, affecting the molding quality, and increasing the difficulty of design, so as to achieve the effect of ensuring smooth removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

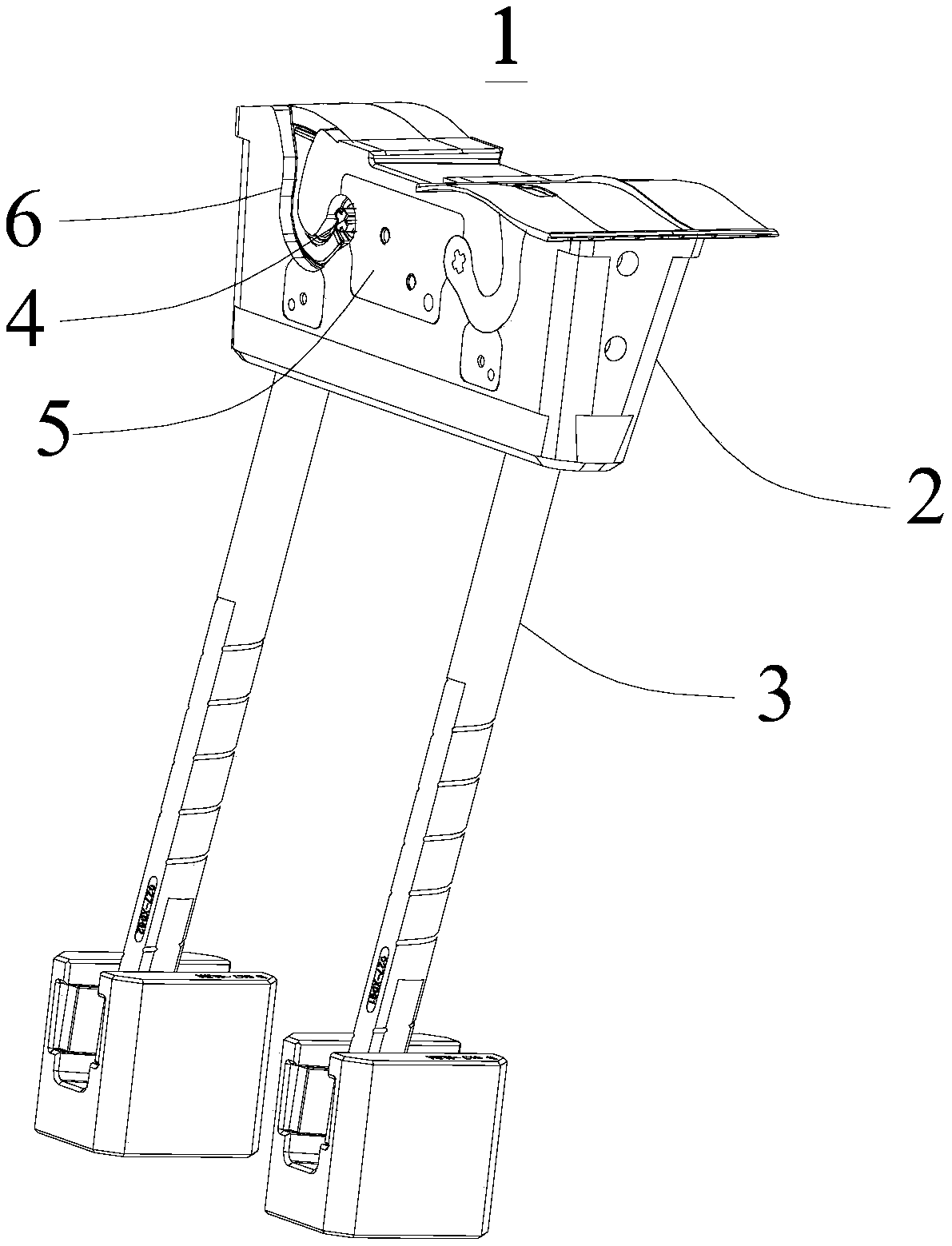

[0041] see in conjunction Figure 1 to Figure 3 , this embodiment provides a secondary buckle forming inclined top device 1, which is used to cooperate with the mold core to form the buckle structure and the buckle groove structure of the product.

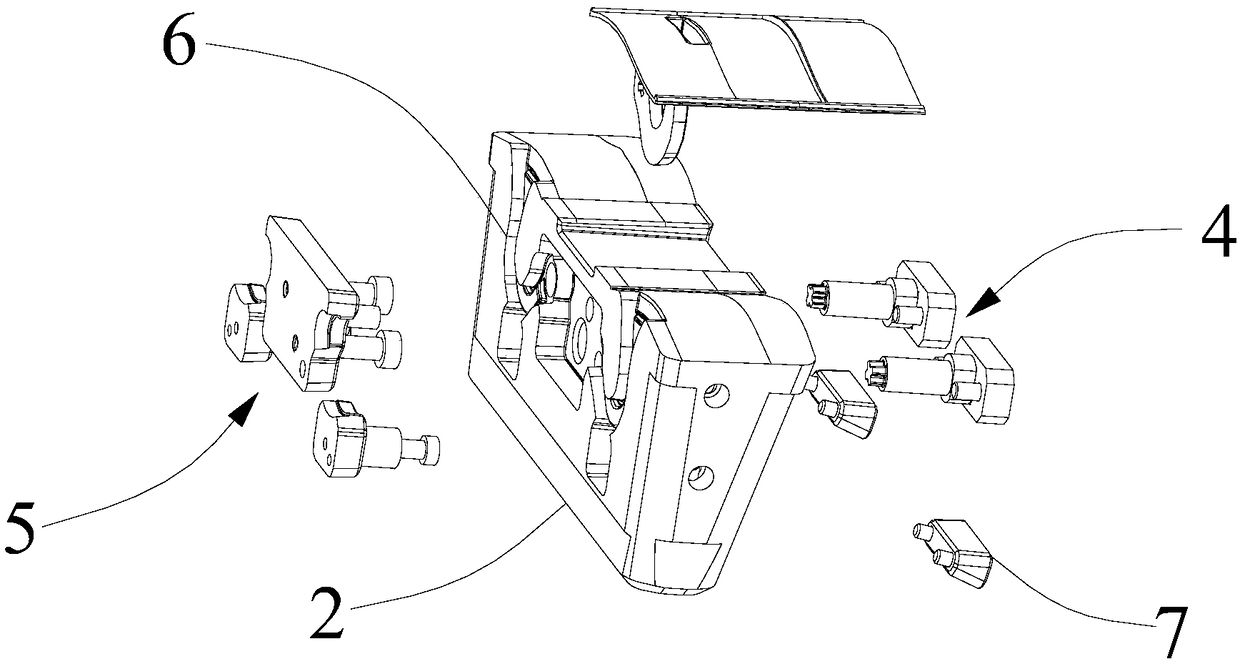

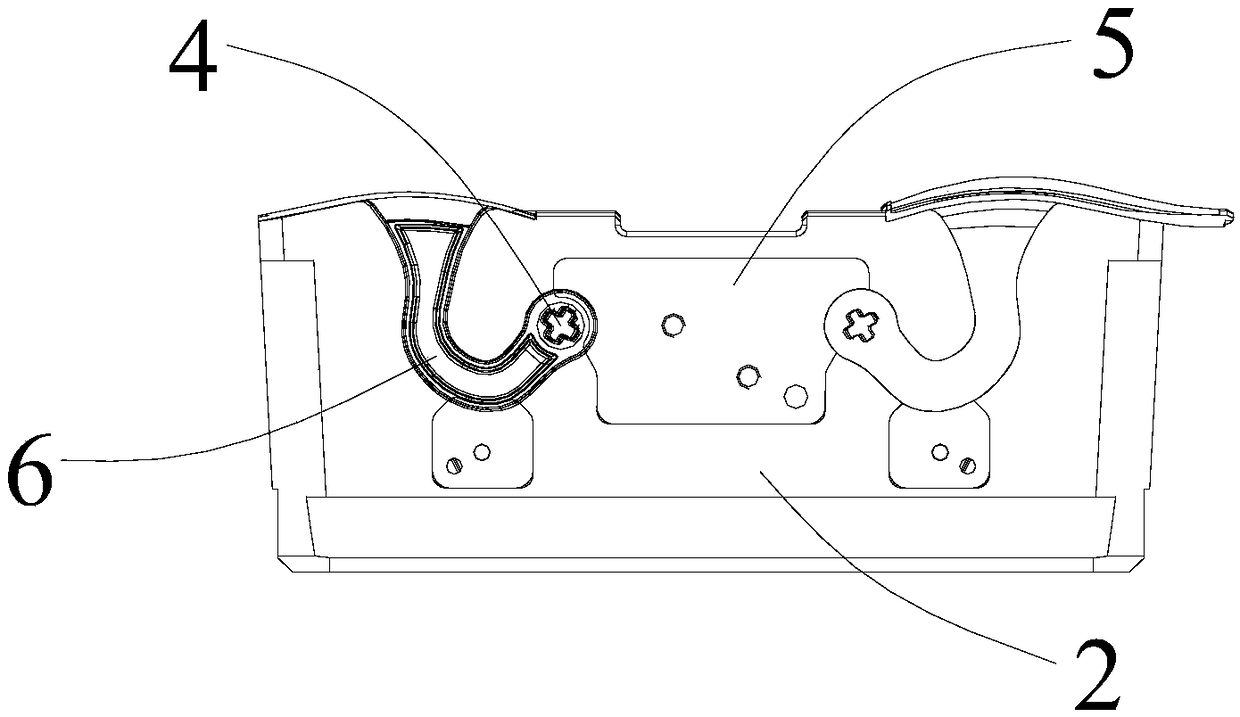

[0042]This secondary buckle forming inclined ejector device 1 comprises an inclined ejector head 2, an inclined ejector rod 3, a buckle forming insert 4 and a ejector block ejection assembly 5, the inclined ejector rod 3 is connected with the bottom of the inclined ejector head 2, and the inclined ejector head 2 has an opposite The front and back of the slanted head are provided with a molding groove 6 on the front of the slanted head, and the back of the slanted head 2 is provided with a needle jack, which runs through the slanted head 2 and communicates with the molding groove 6, and the buckle is formed with a 4 It is detachably arranged on the back of the slanting head 2 , and the end of the buckle molding insert 4 is inserted ...

no. 2 example

[0060] This embodiment provides an injection mold, which can form the buckle and the buckle groove at one time, which reduces the processing and material costs, and at the same time does not need to drive different mechanisms separately, shortens the injection molding cycle, and avoids the abnormal cooperation of different mechanism components situation arises. The injection mold includes a mold core and a secondary buckle forming inclined roof device 1, wherein the basic structure, principle and technical effect of the secondary buckle forming inclined roof device 1 are the same as those of the first embodiment. For a brief description, this embodiment For some parts not mentioned, reference may be made to the corresponding content in the first embodiment.

[0061] The secondary buckle forming inclined jacking device 1 includes an inclined jack 2, an inclined ejector rod 3, a buckle forming insert 4 and a ejector block ejection assembly 5, the inclined ejector rod 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com