Sodium remover for removing organic sodium salts in crude oil

A crude oil desodium agent and desodium technology, which is applied in the field of sodium remover, can solve the problems of difficult removal, poor solubility of sodium and salt, and sodium hazard spread, etc., and achieve the effect of effective removal, convenient use, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

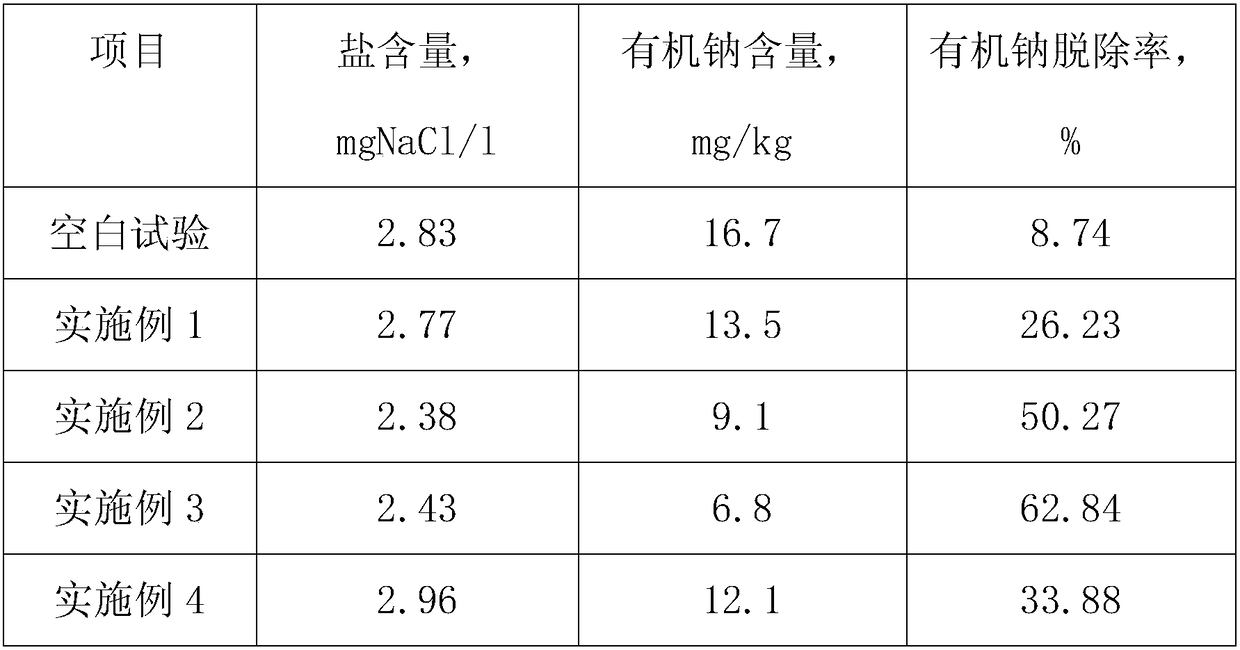

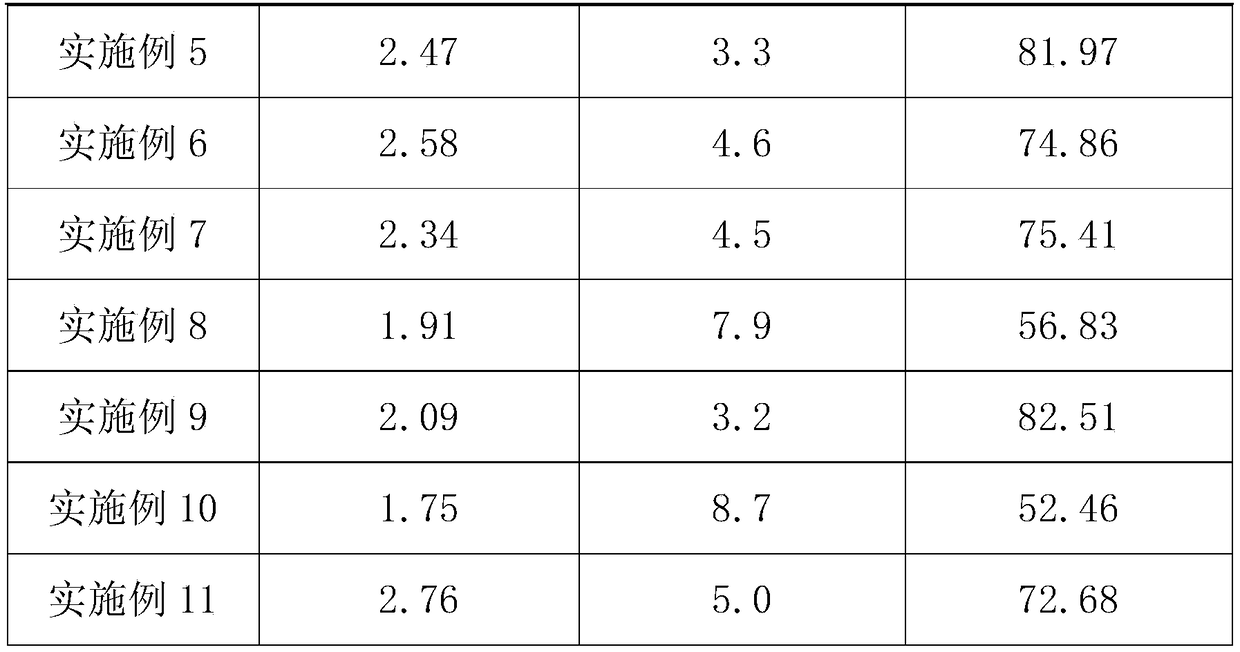

Examples

Embodiment 1

[0021] A desodiumizing agent suitable for organic sodium salts in crude oil, which is a solid mixture of organic ammonium salts and inorganic ammonium salts, including 5 parts of ammonium acetate, 35 parts of ammonium phosphate, 20 parts of diammonium hydrogen phosphate, 20 parts of ammonium nitrate, and 20 parts of ammonium chloride.

Embodiment 2

[0023] A sodium removal agent suitable for organic sodium salts in crude oil, which is a solid mixture of organic ammonium salts and inorganic ammonium salts, including 20 parts of ammonium acetate, 30 parts of hexahydroxy ammonium antimonate, 10 parts of ammonium oxalate, and 15 parts of ammonium citrate Parts, 20 parts of ammonium acrylate, 5 parts of ammonium sulfate.

Embodiment 3

[0025] A desodiumizing agent suitable for organic sodium salts in crude oil, which is a solid mixture of organic ammonium salts and inorganic ammonium salts, including 50 parts of ammonium acetate, 10 parts of hexahydroxy ammonium antimonate, 20 parts of ammonium bicarbonate, and 20 parts of ammonium carbonate share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com